Introduction

This book contains learning ressources and tutorials about many of the technologies we used for our participation(s) in the Eurobot contests.

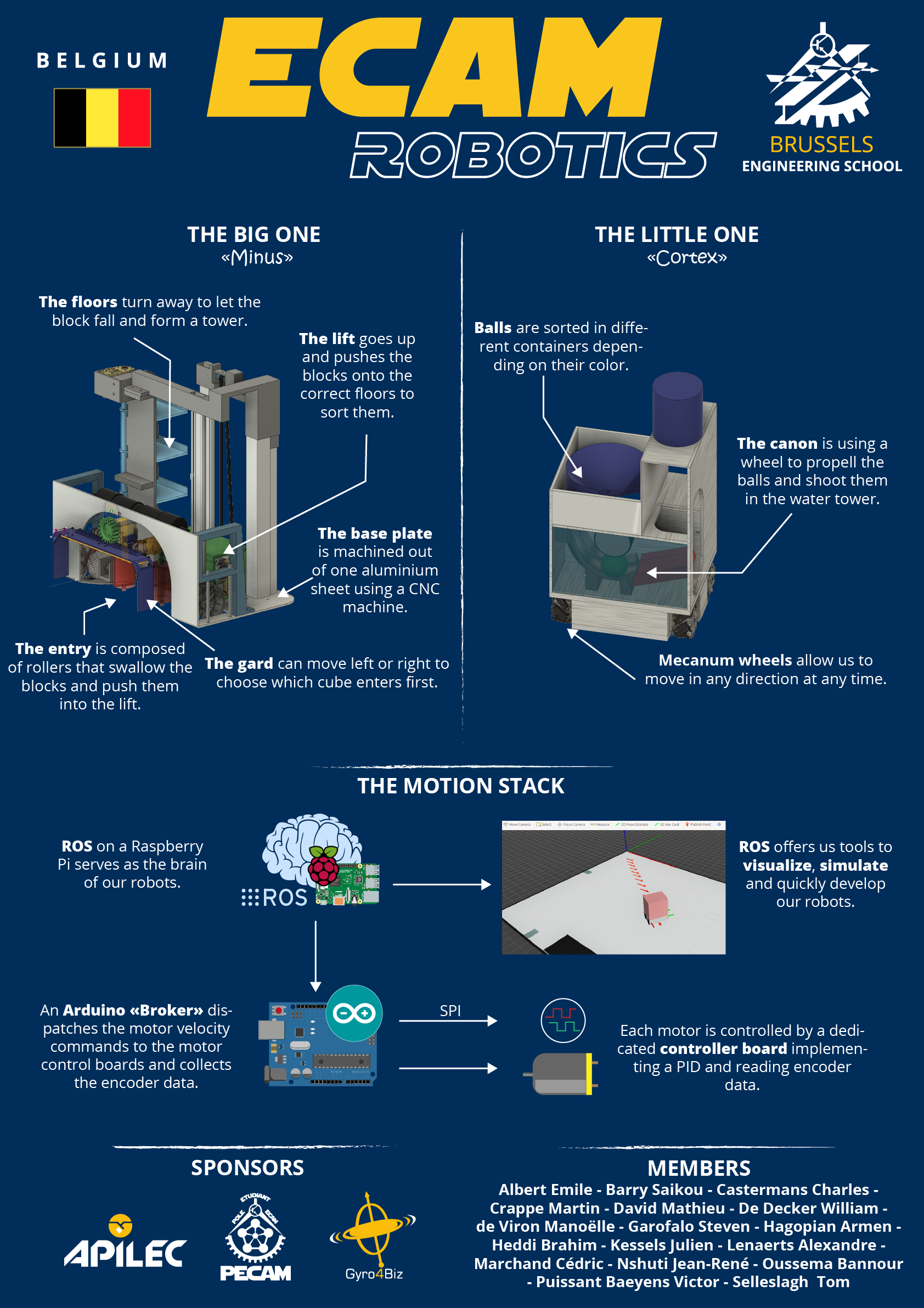

The Eurobot contest is an international amateur robotics contest. The objective is to build an autonomous robot that needs to accomplish a given set of tasks, earning you points.

Through this book, we hope to be able to transfer the knowledge and experience we have acquired during our participation to the team that will participate next year. Our hope is that over the years, this ressource will grow with each participation to become a huge source of information for anyone that wants to participate in the contest.

2018

2019

Organization

When working in a team, it is crucial to have a good way to share files, code and ressources with other members of the team. In this chapter, we explain what tools we used and how we organized our workflow for a good cooperation.

To share code, we use GitHub and git,

we have a shared Fusion360 project to store our 3D models and we have a Google Drive / OneDrive to

store all other files.

We create an office Teams to share all the non-officials files. So everybody have aces to all the information. It was the centralized drive.

GitHub

GitHub is a hosting service for software projects that use git for version control.

GitHub allows us to upload software projects to the cloud in order to facilitate collaboration. You can control who can and can't

contribute to a project and provides tools like bug tracking.

It is important to note that GitHub and Git are very separate things.

- Git is a version control system that allows to keep a history of changes made to source code files

- GitHub is a hosting service that allows to upload Git repositories to the cloud for easier collaboration and sharing

Introduction to Git and GitHub

If you have never used Git or GitHub, we recommend that you get familiar with it. They are incredibly powerful tools. GitHub has a series of simple tutorials that you can follow to get the basics. We particularily recommend to read at least:

- Hello World to learn how to create a repository on GitHub

- Understanding the GitHub Flow to learn how to use GitHub's Web interface to contribute to a project

- Git Handbook to learn the basics of Git and how to do the same as the tutorial above but using Git directly in the command line. Using the terminal may not seem intuitive, but once you understand how it works, it will greatly improve your productivity.

- Forking Projects to learn how to contribute to projects where you don't have write permissions.

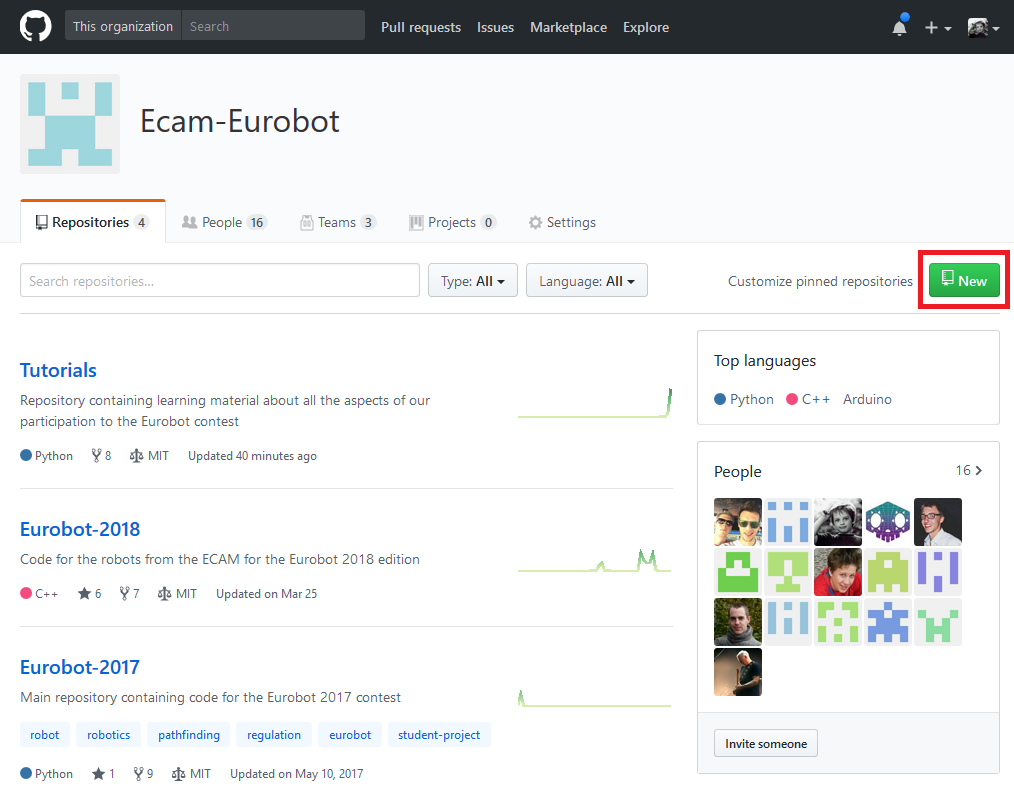

Ecam-Eurobot organization

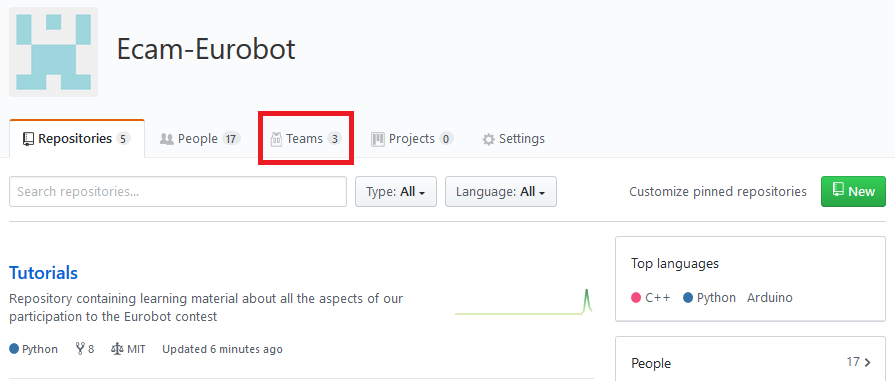

GitHub allows us to create organizations so that multiple users can easily contribute to multiple projects in the organization. We created the Ecam-Eurobot organization to put all our code under.

You can for example find the 2018 repository containing the codes for the 2018 robots, or the source code for this book in the Tutorials repository.

We create a new repository for each year. This allows us to keep old members in the organization with write access to the projects they made and welcome new members with write access to the repository they contribute to.

Administration

To add new members to the organization and configure their permissions, we need an administrator. Each year an administrator is designed who preferably has experience with Git and GitHub in order to help his peers and resolve any Git problems they may face.

This chapter is destined for the person who administrates the GitHub organization

The administrators for past years were:

- 2019 @Diab0lix (Thierry Frycia)

- 2018 @azerupi (Mathieu David)

- 2017 @charlesvdv (Charles Vandevoorde)

You can contact them (most recent first preferably) if you are the chosen administrator for your team. They will add you with the correct privileges.

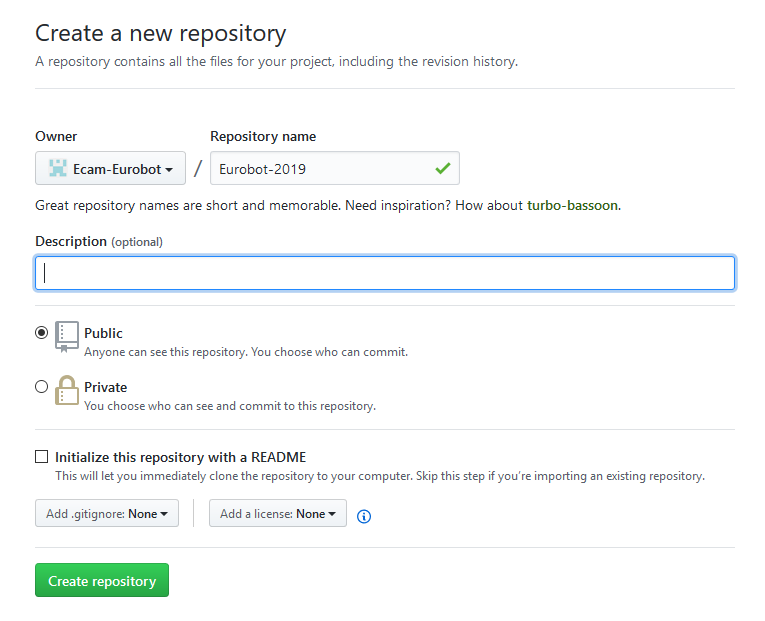

Creating a new repository

As administrator, your task is to setup GitHub and the repositories so that everyone can work on the project. The first thing you want to do is create a new repository for your year.

We do however recommend to base it off off the repository from previous year instead of starting from scratch. As administrator, head over to the organization's page to create a new repository.

Fill in the name with Eurobot-xxxx where xxxx represents the year. You can add a description if you want. Leave all

the rest blank because we are going to push the code of previous year in the newly created repository.

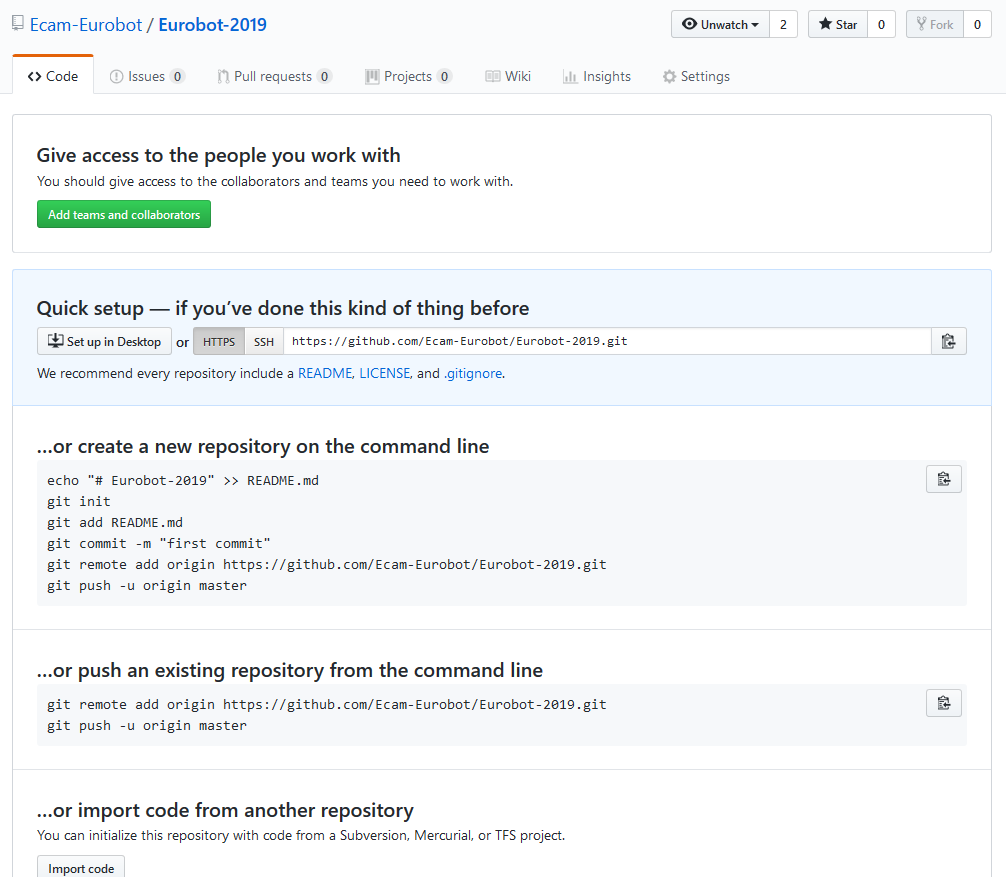

You will land on the following page

Let's push the repository from last year into the newly created repository. On the command line, clone last years repository. In this case, I will clone Eurobot-2018

git clone https://github.com/Ecam-Eurobot/Eurobot-2018.git

cd Eurobot-2018

Now you need to add the newly created repository as a remote. And verify that it was added correctly.

git remote add next-year https://github.com/Ecam-Eurobot/Eurobot-2019.git

git remote -v

Push the repository into the newly created repository

git push -u next-year master

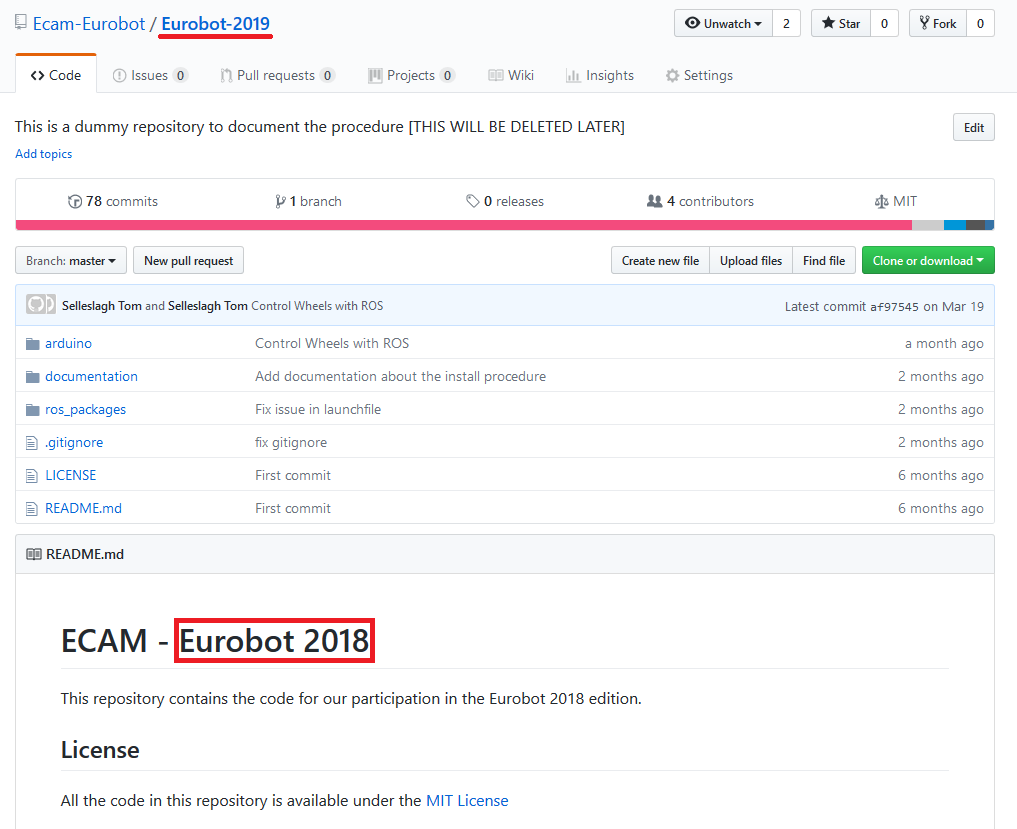

If we refresh the GitHub page for the newly created repository, we can see something similar to below.

We can see (in the top left) that we are in the new repository and if we look at the README at the

bottom we can see that it contains the files from previous year. We can now start to work in the new

repository without affecting the old one.

Note:

Now that the new repository is created, you can remove your local clone of the repository from last year. You will not need it anymore.

Adding teams

Now that the repository is created, you need to add two teams to the Eurobot organization:

- Eurobot <year>: this team will contain all the members participating this year. We will give this team the privileges to push to any branch except the master branch.

- Eurobot <year> Reviewers: this team will be given more privileges. They will be able to review and accept pull requests to the master branch.

Note:

The master branch should always be kept in a working state, this is the golden rule! As administrator, with help from the reviewers, it is your duty to make sure that this rule is followed by everyone. The normal development process should be the following:

- For any new development a new branch is created by the member that develops it

- He implements the new feature / behavior

- When done, he creates a pull request against the master branch

- At least one reviewer reads the changes, makes sure that the code meets the quality guidelines and aproves the changes

- Only then can the code be merged into the master branch.

Resist the urge of merging code that hasn't been reviewed.

To create a new team, go to the GitHub organization: Ecam-Eurobot and go to the "teams" tab.

Then click the "New team" button, fill in the name as mentioned above and then click "Create the team".

Give them correct permissions

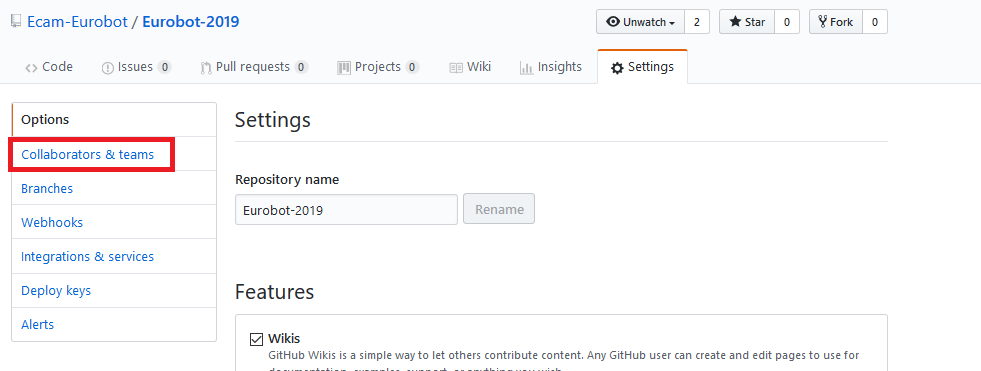

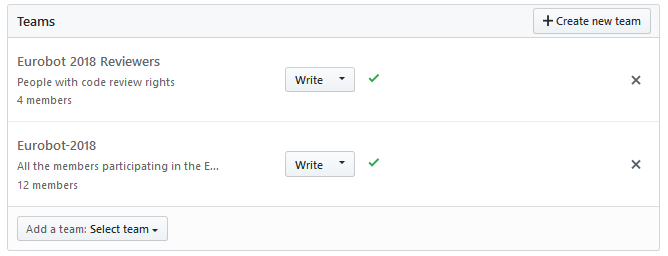

Now that the teams are created, we need to give them the correct permissions. Go to the newly created repository, under "Settings" go to the "Collaborators & Teams" section.

Then add the teams you created with the write permissions, like below.

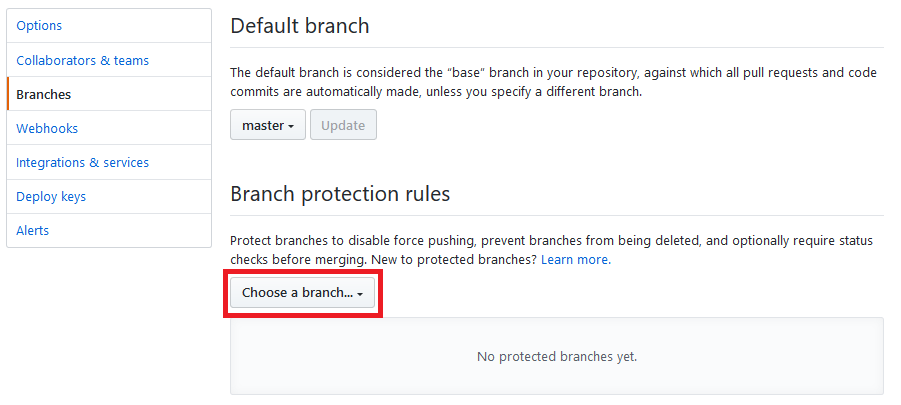

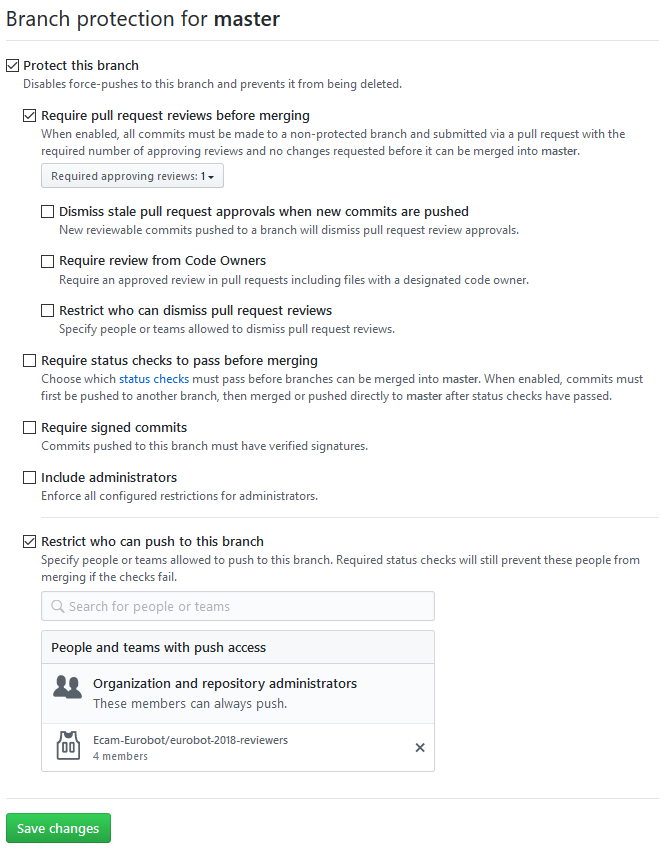

Now go to the "Branches" section and add the master branch as a protected branch.

And configure the protections like in the image below:

This will prevent anyone from commiting to the master branch directly except the administrator and the reviewers, who need push access to accept pull requests. Don't abuse these privileges, it is always better to have your code reviewed by others, even if you are a badass programmer!

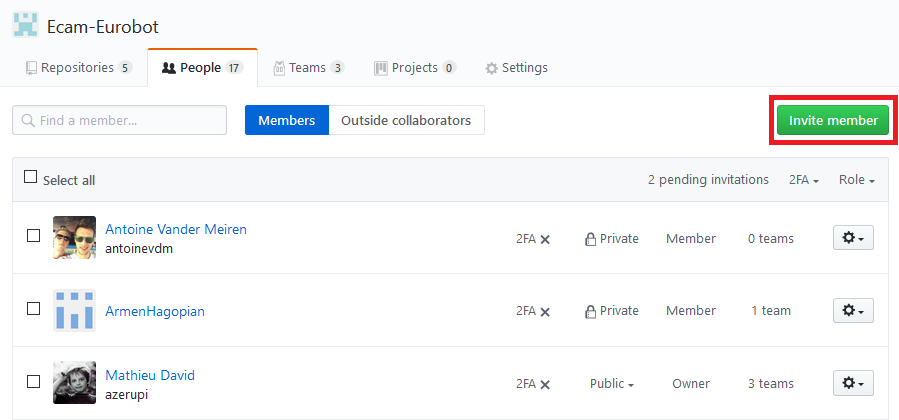

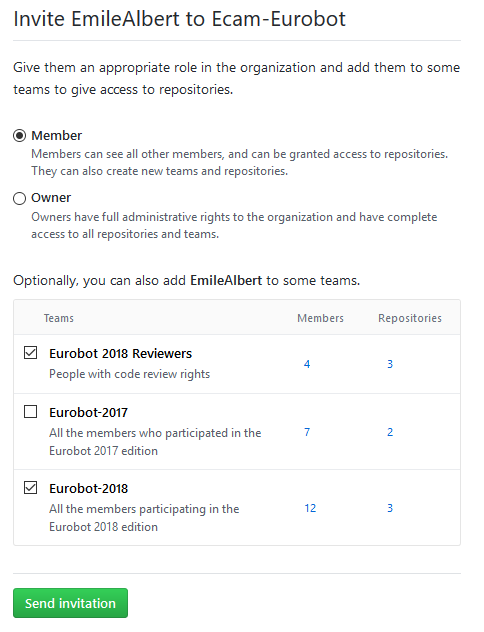

Invite members

Now that everything is setup, we still need to invite the people who will be participating with you this year and assign them to the correct teams. To do this, go to the organization's page again under the "People" tab and click on "Invite member".

Type in their GitHub user name and invite them. In the invitation, you can already assign them to the correct teams.

Once the invitation has been sent, the invited user can accept the invitation by visiting the organization's page: https://github.com/Ecam-Eurobot.

mdBook

To generate this online documentation "book", we use a tool called mdBook. This chapter will briefly introduce this tool in order for anyone to be able to contribute and improve this document.

The official documentation for mdBook can be found here

Structure of a book

A book has the following structure:

book-test/

├── book.toml

├── book

└── src

├── chapter_1.md

└── SUMMARY.md

The book.toml file contains the configuration options of the book.

In this file you can find the title, the authors, but also an option to enable math equation rendering, etc.

For a list of the options, refer to the official documentation. The book.toml file also represents the

root folder of the book. When we run mdBook, we need to either run it in that folder or point it to that folder.

In that same folder, you can find 2 folders: src and book. src contains the source files, written in markdown.

When running the tool, it will take all the files in that directory and compile them into the book which is then stored in the book folder.

Finally, the most important file is the SUMMARY.md file. This file represents the table of content of the book, giving the hierarchy of all the

chapters and where to find their source files. The folliwing is an extract from this books summary file.

# Summary

[Introduction](introduction.md)

- [Organization](organization/organization.md)

- [GitHub](organization/github.md)

- [Administration](organization/gh-admin.md)

- [mdBook](organization/mdbook.md)

- [Mechanical](mechanical/mechanical.md)

- [3D modeling with Fusion360](mechanical/fusion.md)

- [3D printing](mechanical/3d-print.md)

- [Mecanum wheels](mechanical/mecanum.md)

We can see that it is simply a set of nested markdown lists containing links to the source files.

Markdown

The source files for the book are written in Markdown, which is a very simple markup language. You can learn the basics in '60 seconds'.

Syntax highlighting

To insert code blocks with syntax heighlighting, use triple backticks followed by the language name / abreviation:

```python

import sys

sys.exit(0)

```

This will generate the following:

import sys

sys.exit(0)

Images

In mdBook, paths to images should always be referenced from the src folder. So if you image is located in src/img/my-image.png,

you should use .

Generating the book

When you make changes locally, you probably want to see how it looks before making a commit. You can install the tool for this. At the time of writing, [pre-built binaries] exist for Linux and MacOS, but not for Windows.

For windows, I have compiled a binary that you can use. You can also compile mdBook from source, but this falls outside the scope of this tutorial.

When you have mdBook, add it to your path so that you can use it in the terminal / command line from anywhere. For this, I will refer you to external documentation: Linux / MacOS & Windows.

Now everything is setup, you should be able to open the terminal / command line and type mdbook --help and see the following:

mdBook --help

mdbook v0.1.5

Mathieu David <mathieudavid@mathieudavid.org>

Create a book in form of a static website from markdown files

USAGE:

mdbook.exe [SUBCOMMAND]

FLAGS:

-h, --help Prints help information

-V, --version Prints version information

SUBCOMMANDS:

build Build the book from the markdown files

clean Delete built book

help Prints this message or the help of the given subcommand(s)

init Create boilerplate structure and files in the directory

serve Serve the book at http://localhost:3000. Rebuild and reload on change.

test Test that code samples compile

watch Watch the files for changes

For more information about a specific command, try `mdbook <command> --help`

Source code for mdbook available at: https://github.com/rust-lang-nursery/mdBook

The two command that are the most interesting for you are build and serve.

Running mdbook build in the folder where the book.toml is located will generate the book.

The generated book can then be found in the book/ folder.

Running mdbook serve is even better, because it will watch the files for any changes and rebuild the book automatically.

On top of that, it serves the book on http://localhost:3000 and automatically refreshes the browser after regenerating the book.

You launch it once, when you begin to write and forget about it. It is that simple.

Hosting

When you visit the following address: https://ecam-eurobot.github.io/Tutorials/ you can find this book online.

To host the website, we use GitHub. In the repository of the book, there is a branch called gh-pages. This is a special branch that can be used to host a

static website through GitHub.

When you push a new version of the generated book to this branch, it will be accessible online from the address above.

Note:

Don't push manually to this branch. As explained below, a new version of the book is generated and pushed automatically on each new commit on the master branch!

Travis

We have setup Travis to generate the book for each new commit on the master branch. This means that the hosted book is always up to date, with a couple of minutes delay.

The travis configuration file looks like the following:

sudo: false

dist: trusty

language: rust # We want to download the Rust toolchain (because mdBook is written in Rust)

cache: cargo # We want to cache the cargo folder to speed up the compilation of mdBook

rust:

- stable

branches:

only:

- master # We only want to execute Travis for commits on the master branch

before_script:

- (cargo install mdbook --vers ^0.1.5 || true) # Install mdBook (the || true trick is to avoid an error if it is already installed)

script:

- mdbook build # Generate the book

# Deploy the book to GitHub Pages

deploy:

provider: pages

skip-cleanup: true

github-token: $GH_TOKEN # Set in travis-ci.org dashboard, marked secure

keep-history: true

local-dir: book

on:

branch: master

Mechanical

As every year, a big part of conceiving the robot is designing the mechanical parts. The requirements change with the years, but as a big innovation in 2018, we suggest to keep the Mecanum wheels system. According to the rules, you'll have to realize diverse action in order to get points.

For example, in 2018, the actions were:

- Collecting blocs, lift them, sort them according to their color and build a tower with them.

- Collecting balls from a pipe, sort them by color and evacuate them to a lower position and to a higher one.

You'll find more information about the designed mechanisms in the two dedicated chapters (Lift & Ball mechanism).

Before that, we want to introduce you to one of our main tools to design those mechanisms and build them. These are:

- Fusion 360, to design 3D models.

- 3D Printing, to make the pieces we designed or found on the internet fast and cheap.

1. Getting in touch with Fusion360

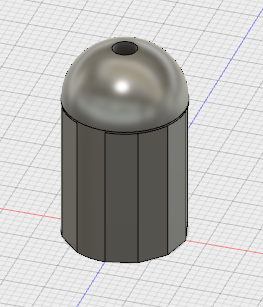

Fusion360 is a 3D modeling software used by many professionals and hobbyists to create pieces. You can directly send your models to slicers in order to print them or export the 2D plans to build it your own. The following chapters should give you a global overview of how Fusion360 works and what you can use it for. We'll try to orient our writing to learn your to design in order to print your models later and will end with some tips about the printing them.

To complete your learning we strongly recommend you subscribe to Lars Christensen's Youtube channel. He's a master in the use of Fusion360 and has very well made videos about every problem or question you might have.

3 videos in particular should hold your attention to get started: Fusion 360 Tutorial for Absolute Beginners— Part 1 and of course Fusion 360 Tutorial for Absolute Beginners— Part 2 and Fusion 360 Tutorial for Absolute Beginners— Part 3.

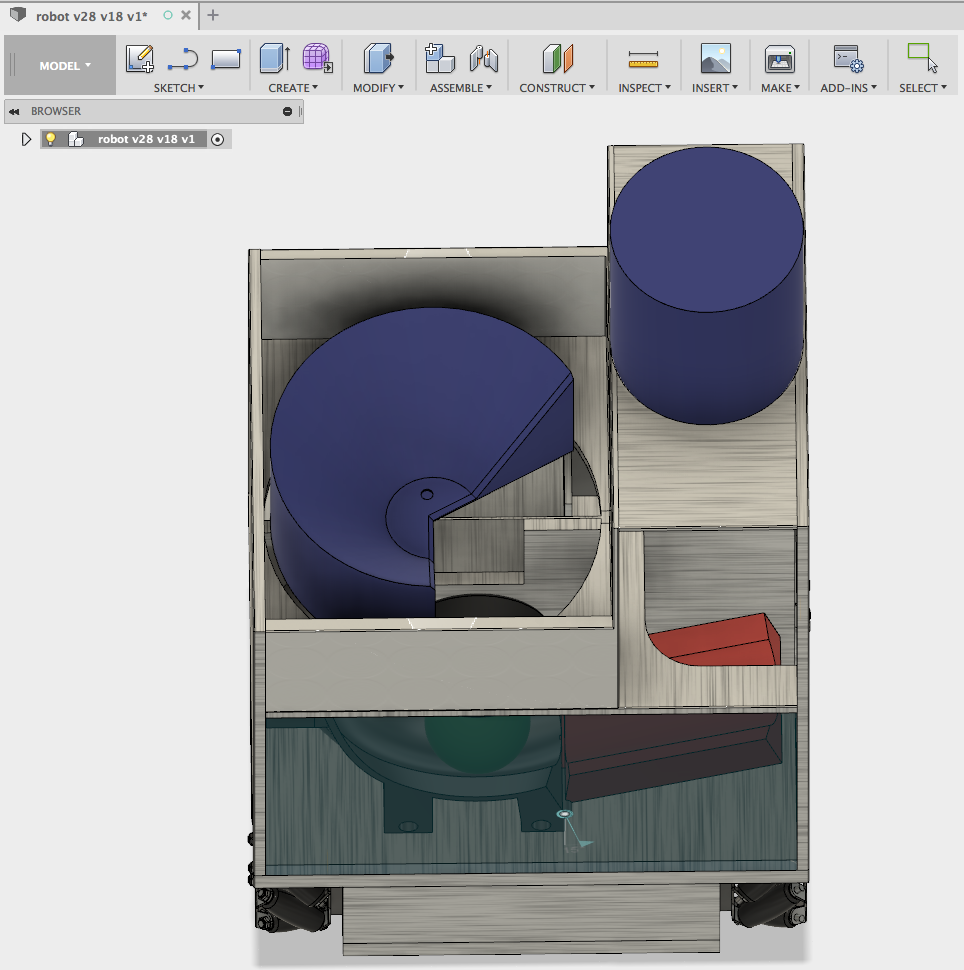

With all these tools in hands we were able to design our robot: Cortex.

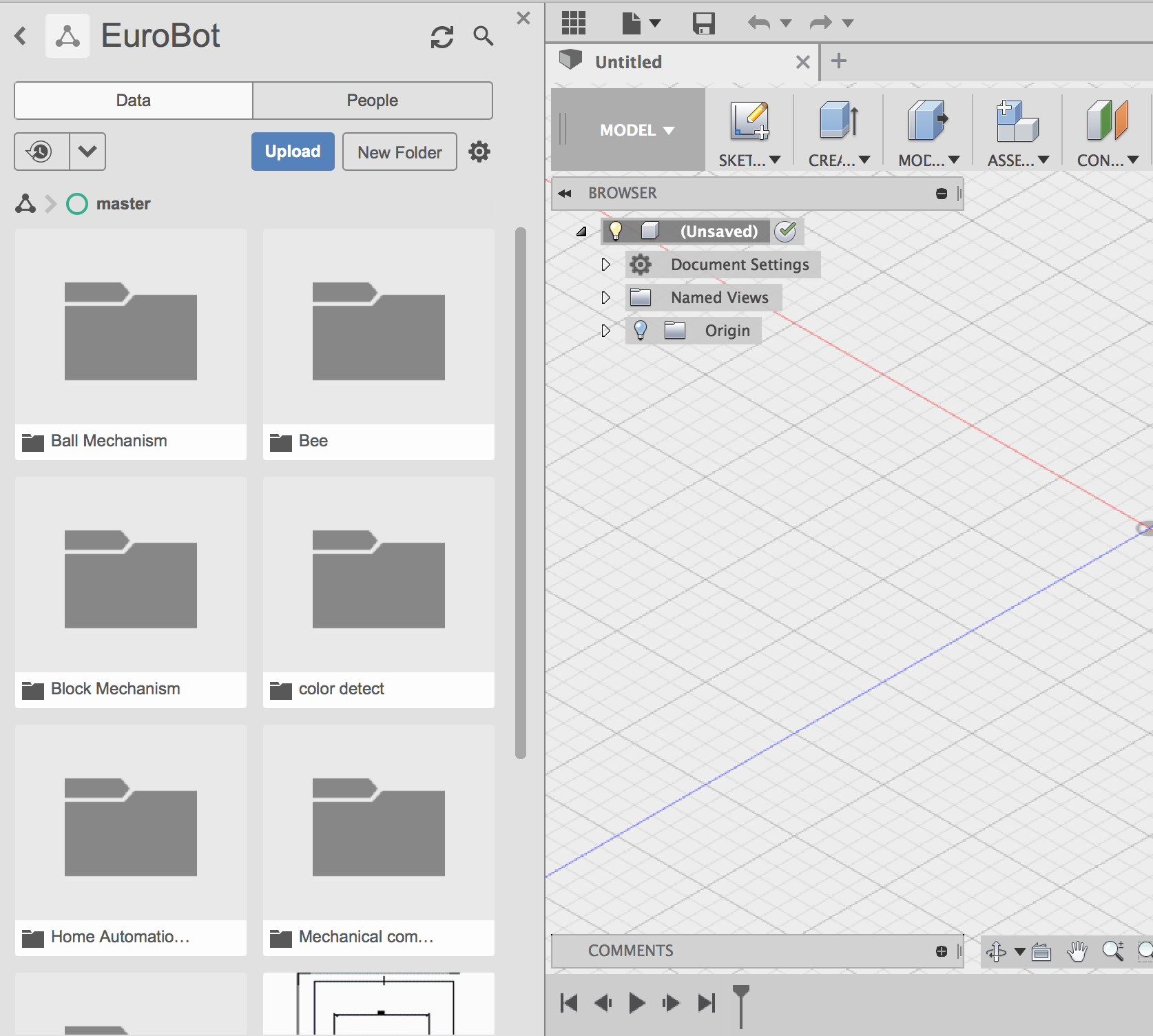

Fusion360 environment

The first window you get when opening Fusion360 should be this.

By clicking on  you access to the repository holding all your folders.

A good practice is to sort them into other repositories according to their relevance. A little bit like you would sort your computer desktop.

you access to the repository holding all your folders.

A good practice is to sort them into other repositories according to their relevance. A little bit like you would sort your computer desktop.

Project view

We'll let you listen to M.Christensen by clicking on the links to the videos we gave earlier to learn the basics of Fusion360. He's an expert on the subject and honestly the only good way to learn this kind of software is by watching someone do and copy. Please don't learn the shortcuts by heart, you'll learn the most used ones by practice.

2. Main Functions and Shotcuts

You should already be able to do your first model now, but in case you misted some of the many things explained by Lars, we would like to give you a quick recap.

To start, note that all functions are easily available trough the "s" key shortcut. Just type a word related to what you are searching for and you'll probably find it directly. Note that you can save them by clicking on the curved arrow.

2.1. Shortcuts

Please don't study them, by the way you probably know most of them after your first hour of practice . If it's still not the case, you'll find them here:

- S=Model Toolbox

- L=Line

- C=Circle

- X=Construction

- D=Dimension

- Q=Push/Pull

- M=Move

- J=Joint

- T=Trim (delete lines)

- Middel button of your mouse = Pan

- Maj+ middel button = 3D move

2.2. Useful functions

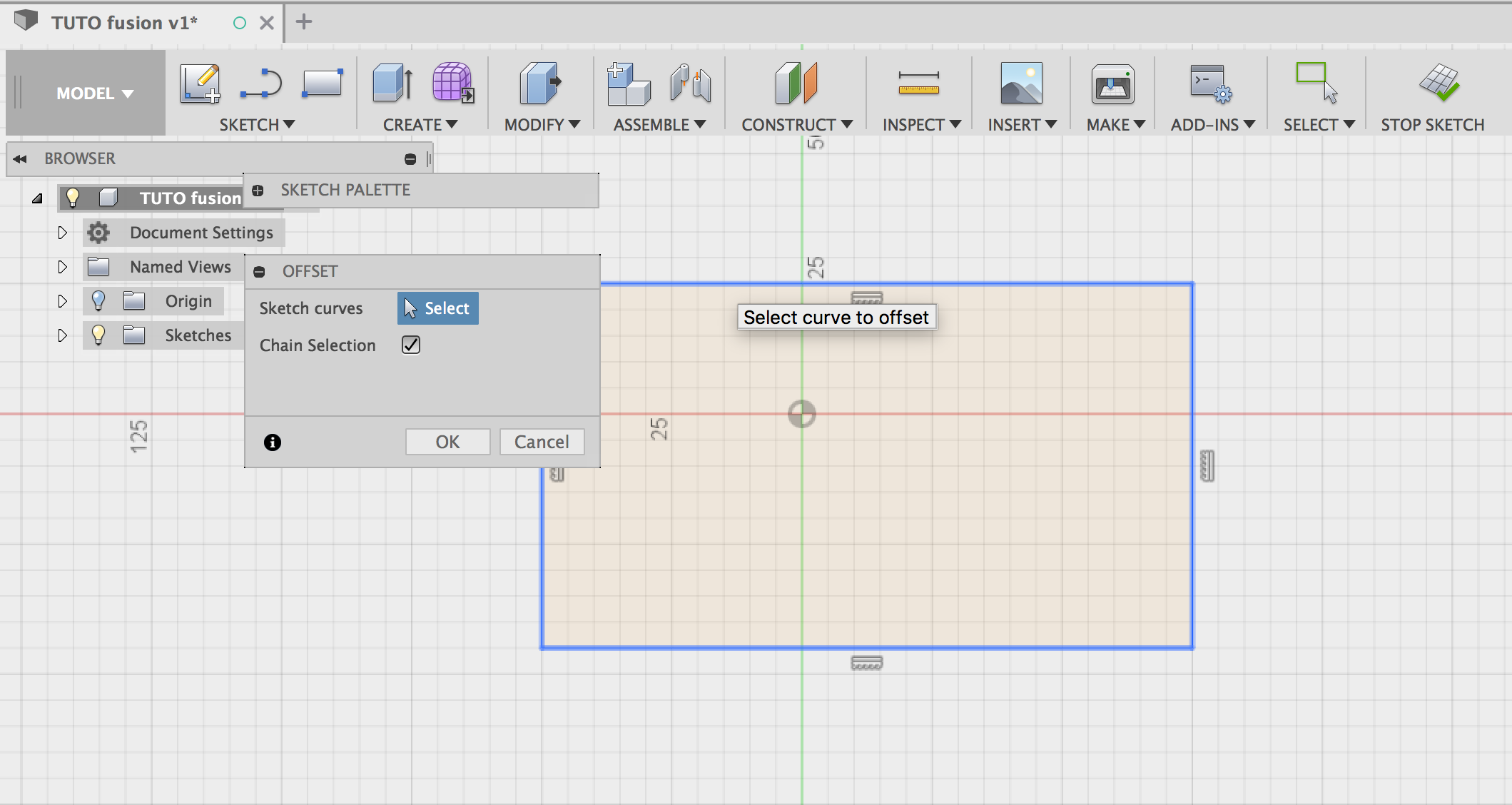

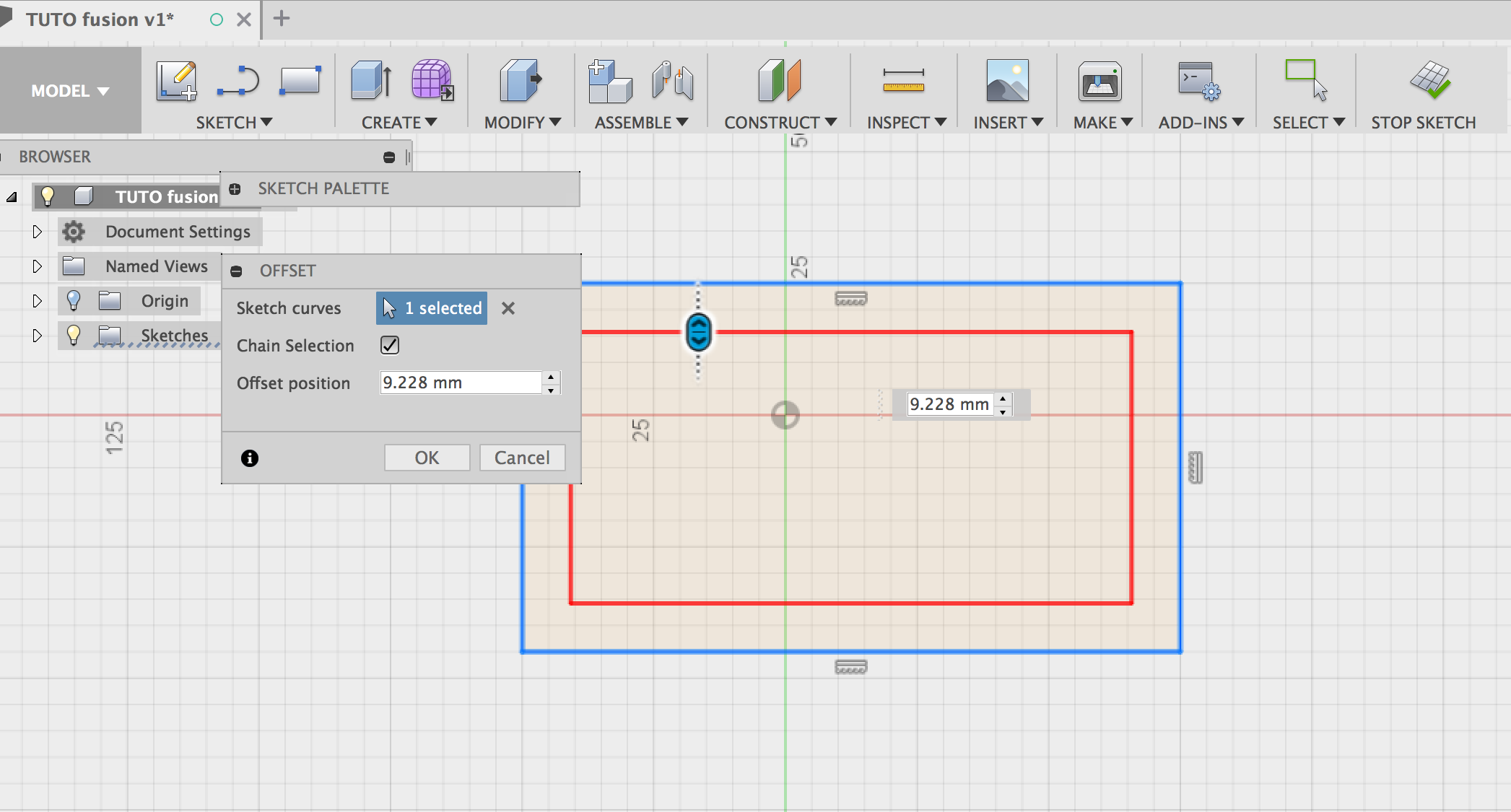

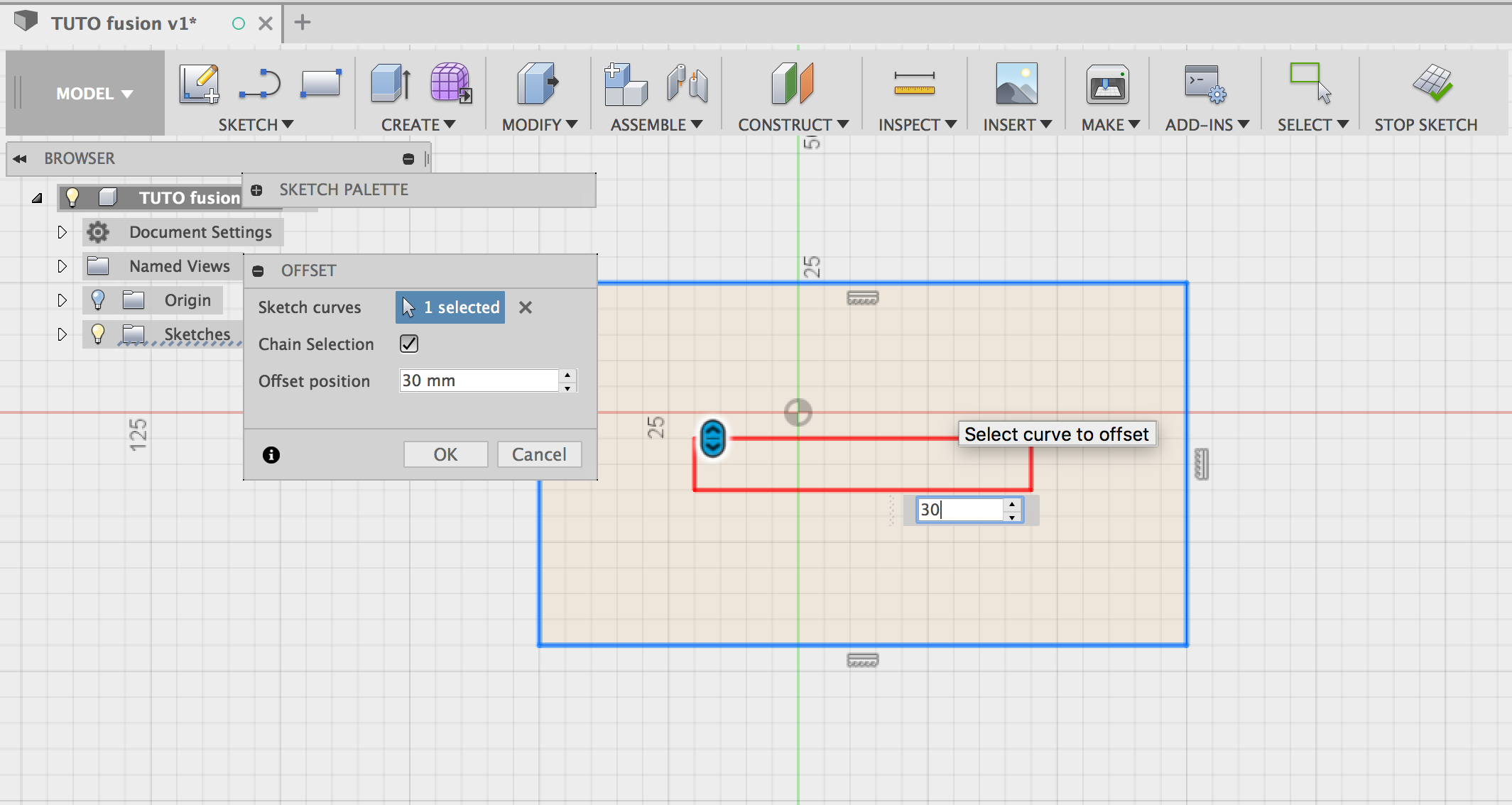

Offset

Offset is a very handy tool when it comes to drawing parallel lines.

The tools works only in sketch mode and you have to already have a reference line (or a shape).

Type the "o" key to open the "offset menu", you then have to select the reference line you want.

You can either drag and drop the cursor with your mouse or type the value you wish the offset to be.

You'll end with the line/shape you selected offset as you wanted.

Sweep

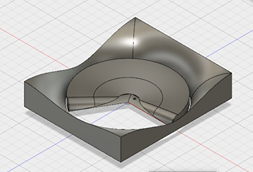

Another useful tool to make pipe, slide and so on is the "sweep" function. Start by drawing a sketch on a

face. In our example it's going to be a double circle.

Then close your current sketch. Go to another face. Start a new sketch . Use "spine" for example and draw a line following as much point as you want.

You'll be able now to use "Sweep", select the space between the two circle as "profile", select the line as "path" and you'll automatically make a curved pipe!

We used it for example for the slide in the 2018's ball mechanism.

Revolve

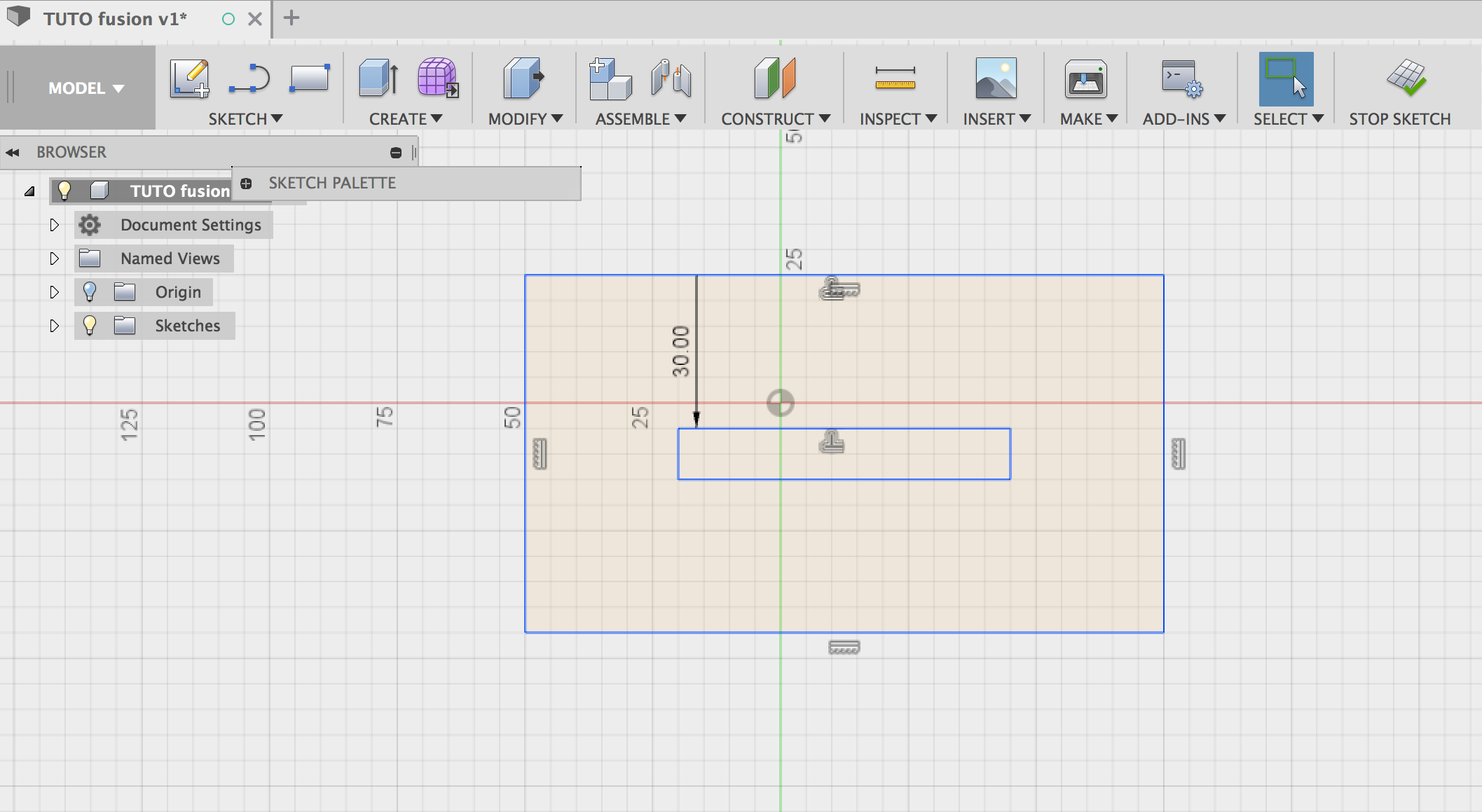

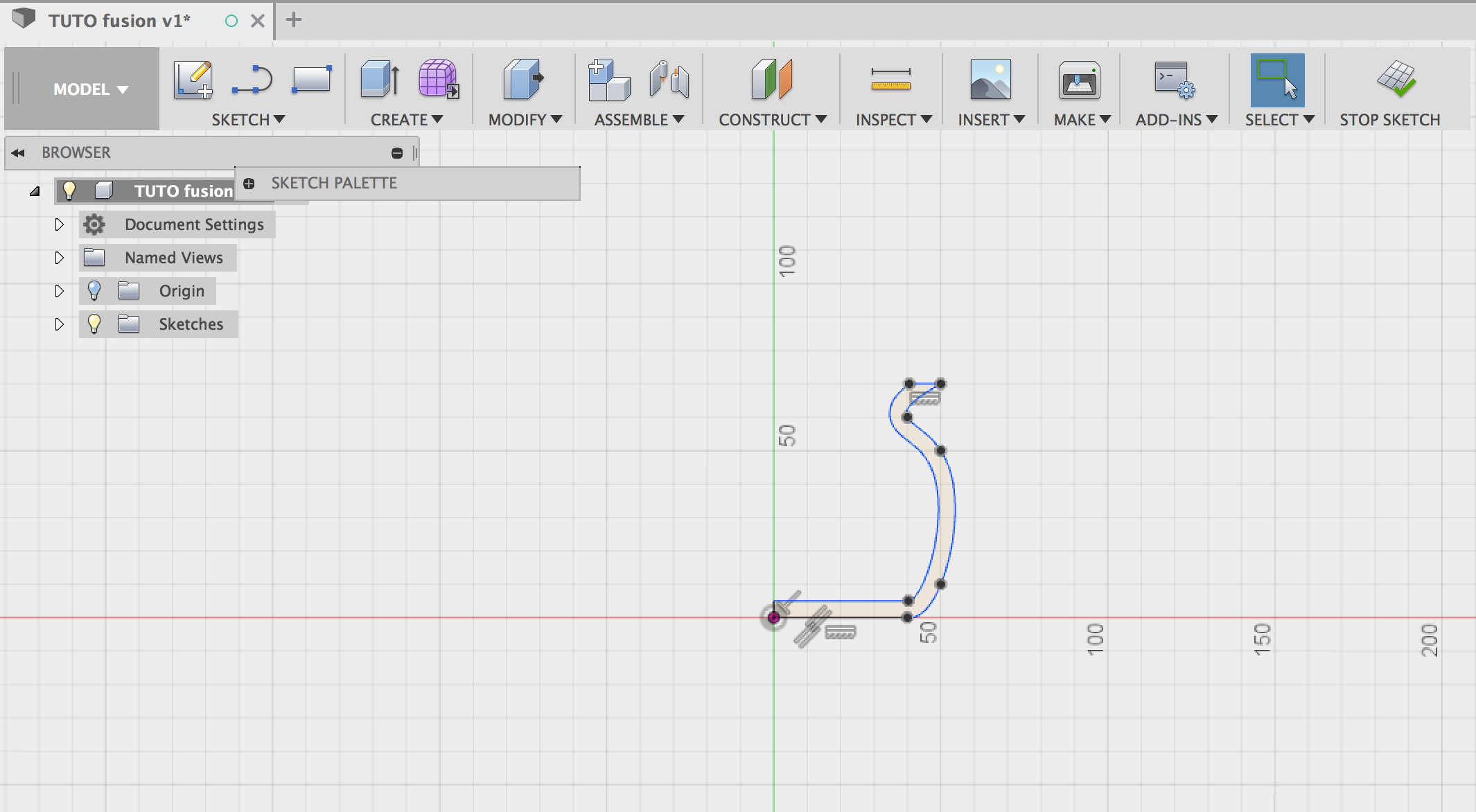

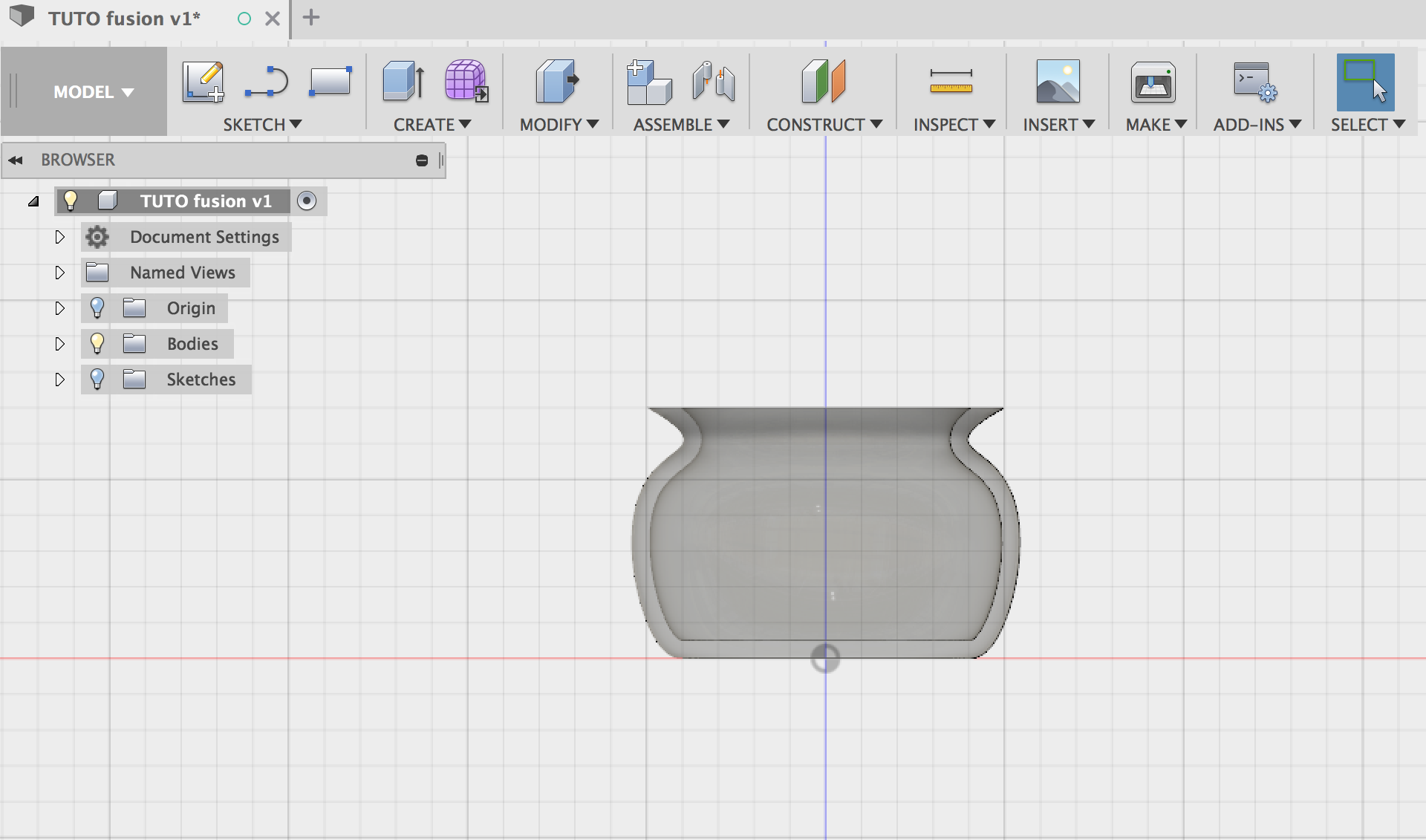

Revolve allows you to create objects as if you turned them on a lathe. It comes in handy to make wheels, cannons, ...

To used it you have to first create a shape around an axis. When you create that shape, you have to imagine it round. So you only have to draw "a half cut of your future object".

Type "s" to access the "search menu" and enter "revolve" to find the tool. You'll have to select the shape and the axis you want and press "enter".

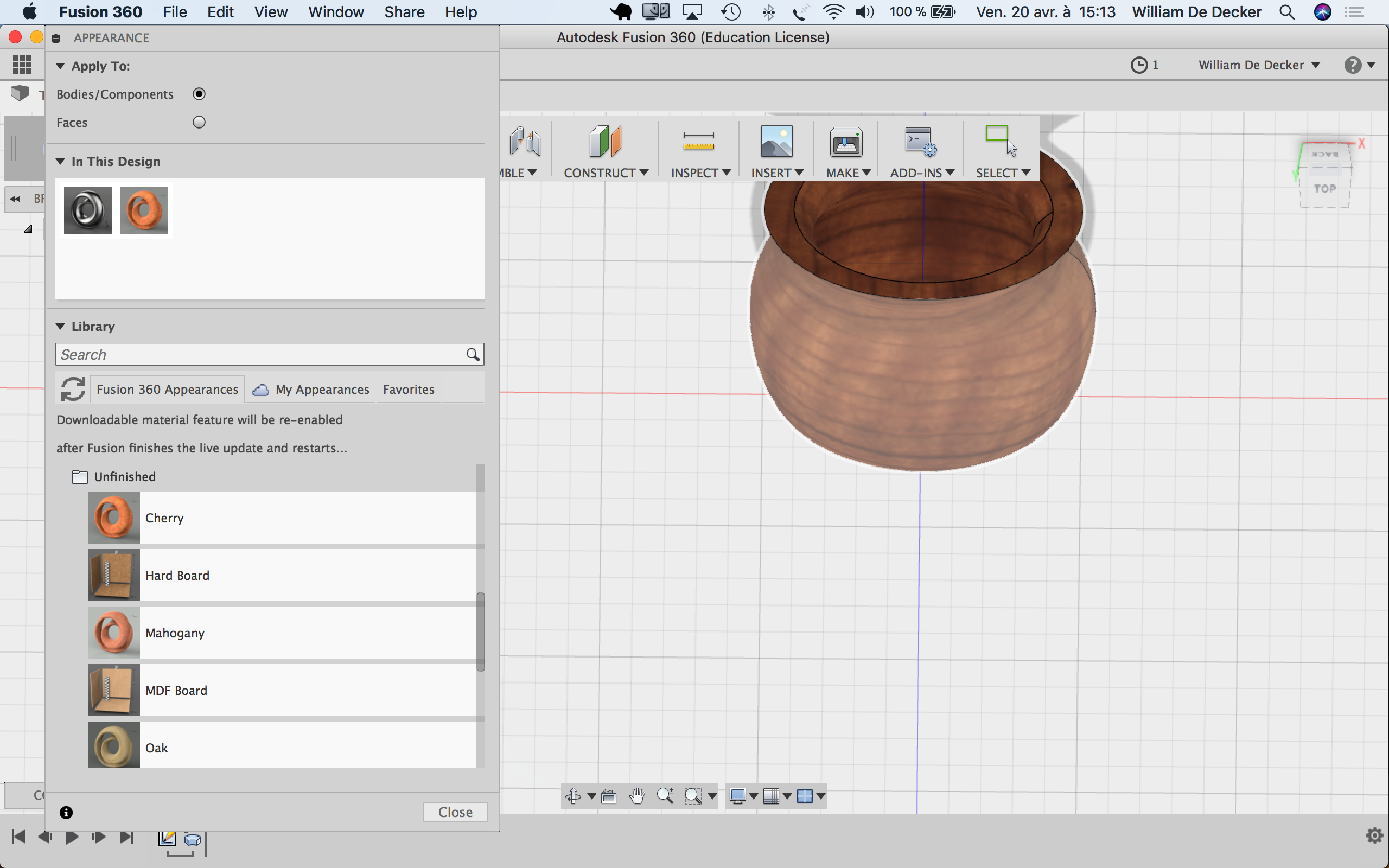

Appearance

To make design easier for others to imagine or simply to choose colors and material purely esthetically, the "Appearance" tool is a must! You can archive more or less the same result with the "Physical Material" tool, but this is more often used for simulation. You can also combine those tools to get for example a steel pipe covered in leather without having to create the wrapping in a new component. It is also very handy when creating complex assemblies with little pieces because the different appearances help to see those different pieces.

Appearance is really easy to use. Type "a", choose the look you like and drag-drop it on the body you want. You can directly drop it in the project tree or on the visual objet.

Pattern

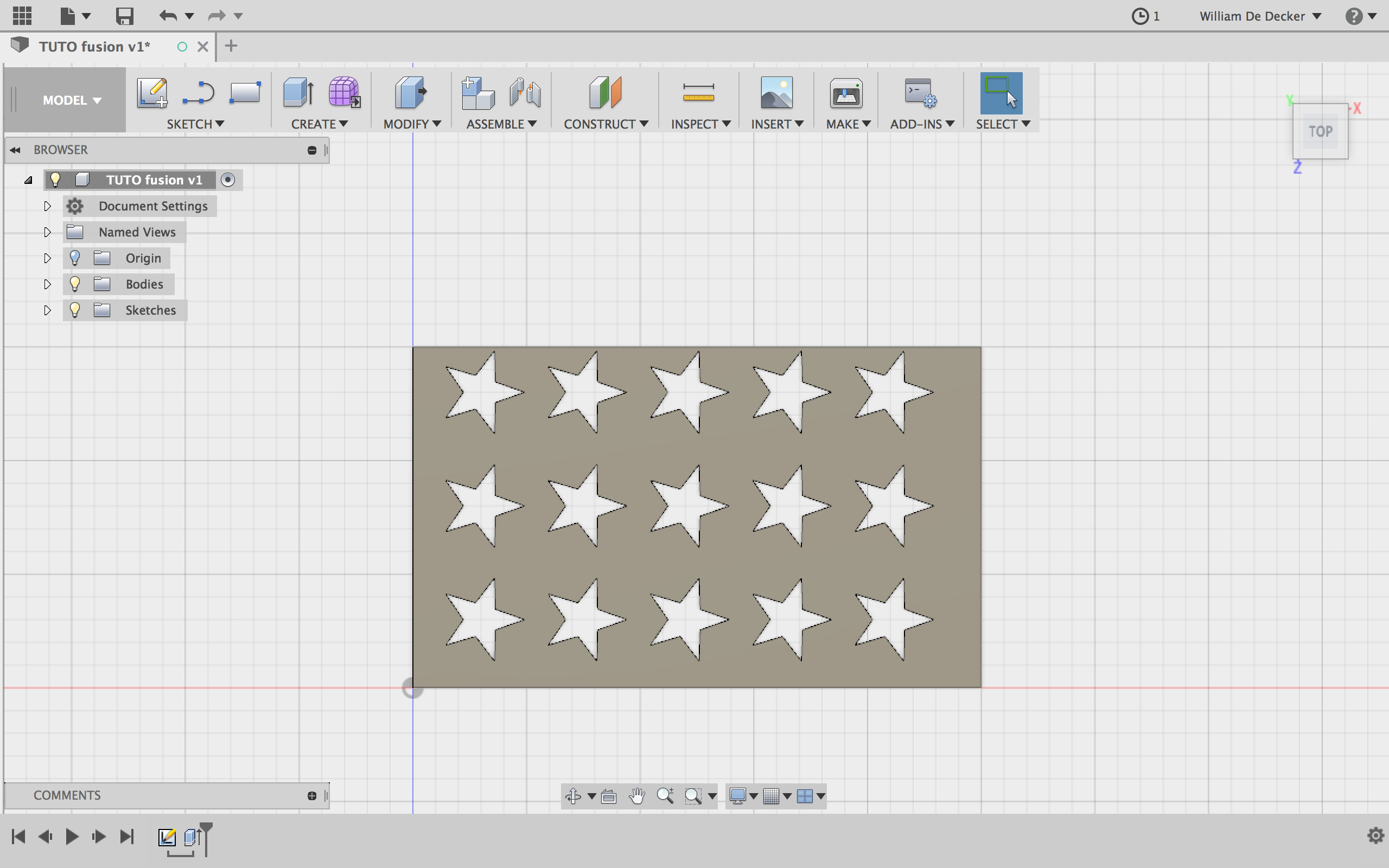

Real time savior, "Pattern" allows you to duplicate sketches, bodies and components on a given distance.

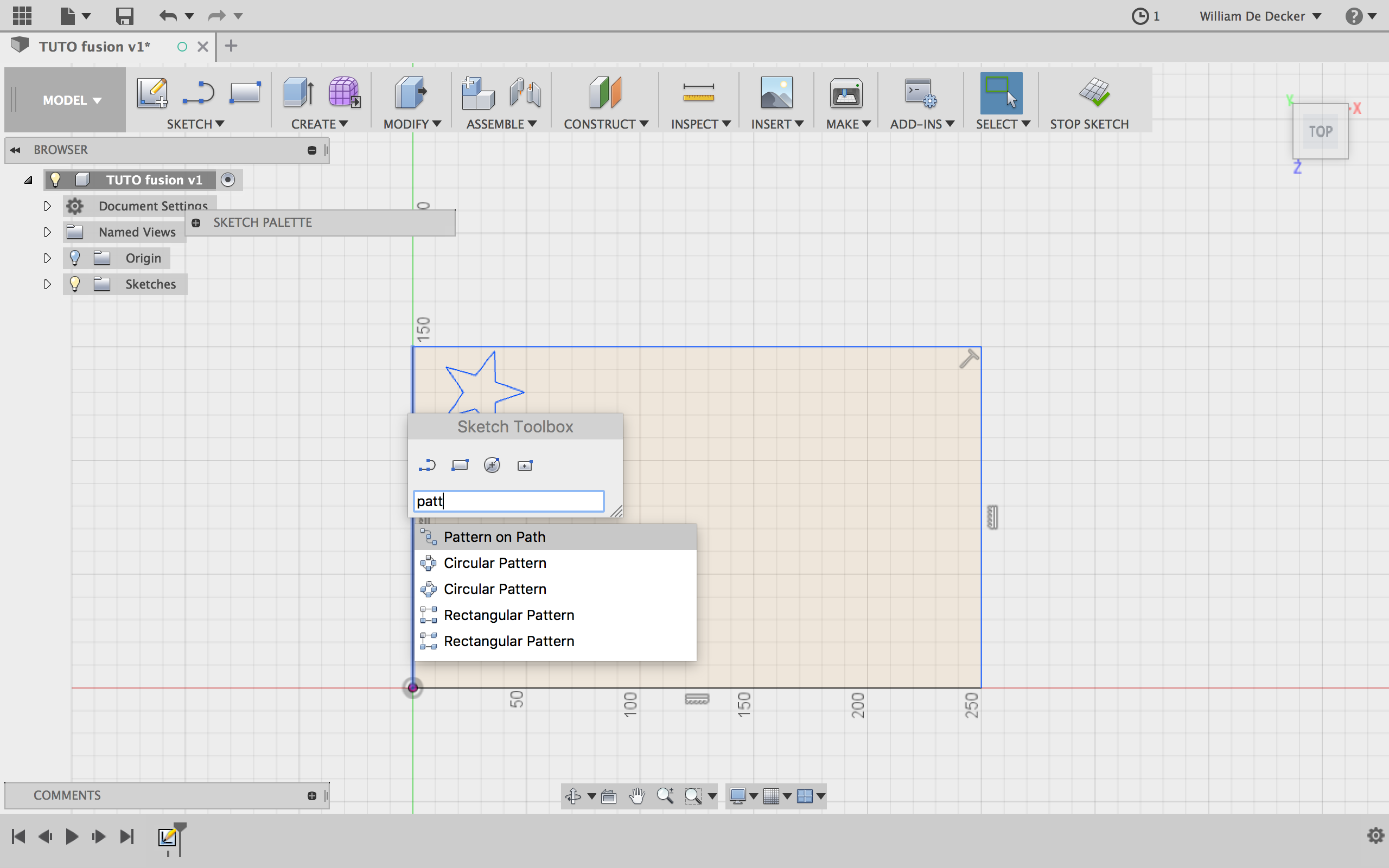

Multiple pattern tools exists. To see then go into the "search menu" and type "Pattern".

As you can see in the above picture, you can create a circular, rectangular or "free style" pattern. For both rectangular and circular patterns the ones with white square create patterns in sketches. The grey ones create patterns of volumes (bodies, components). We'll only present the sketch pattern, but the volumes work in a similar way.

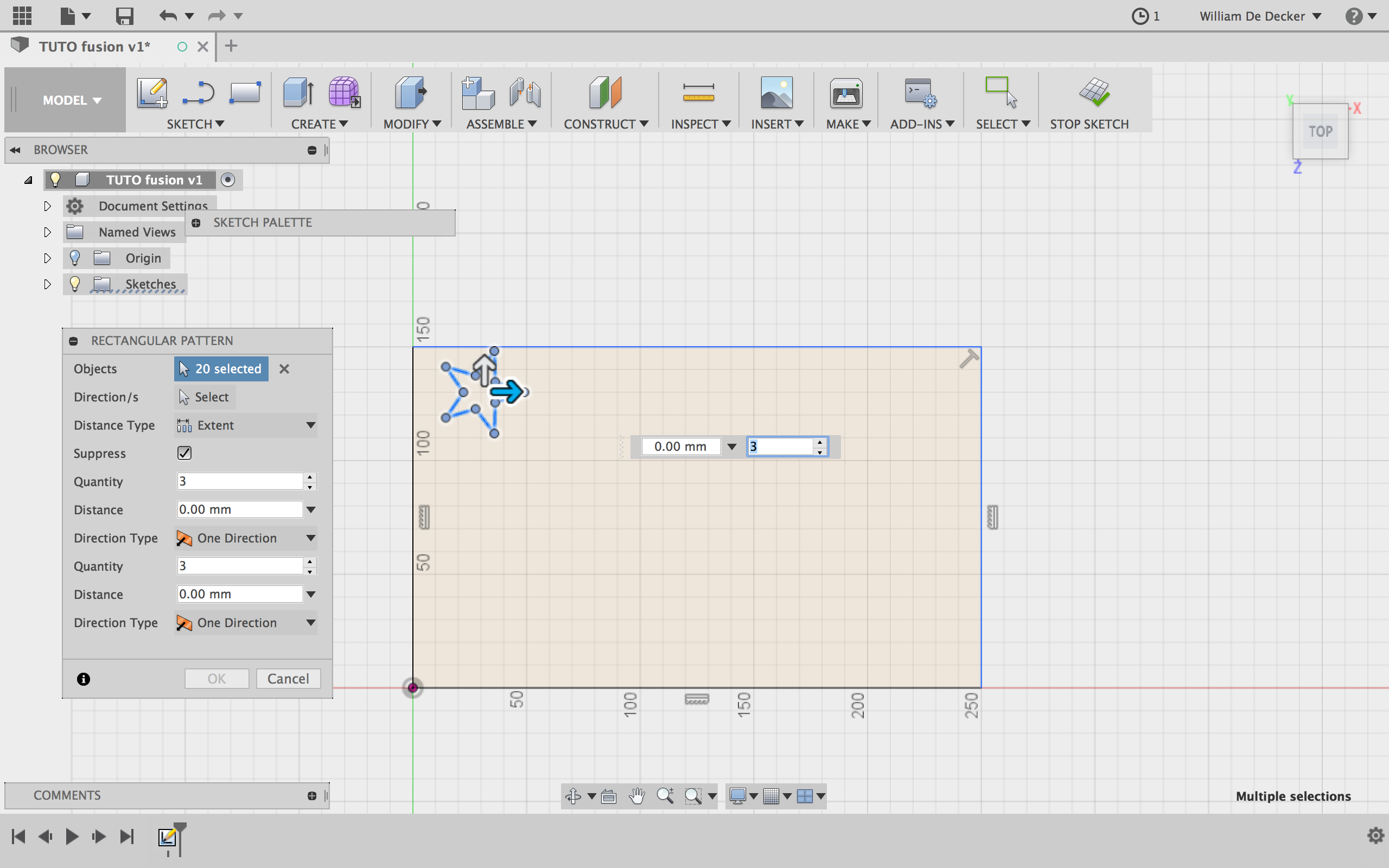

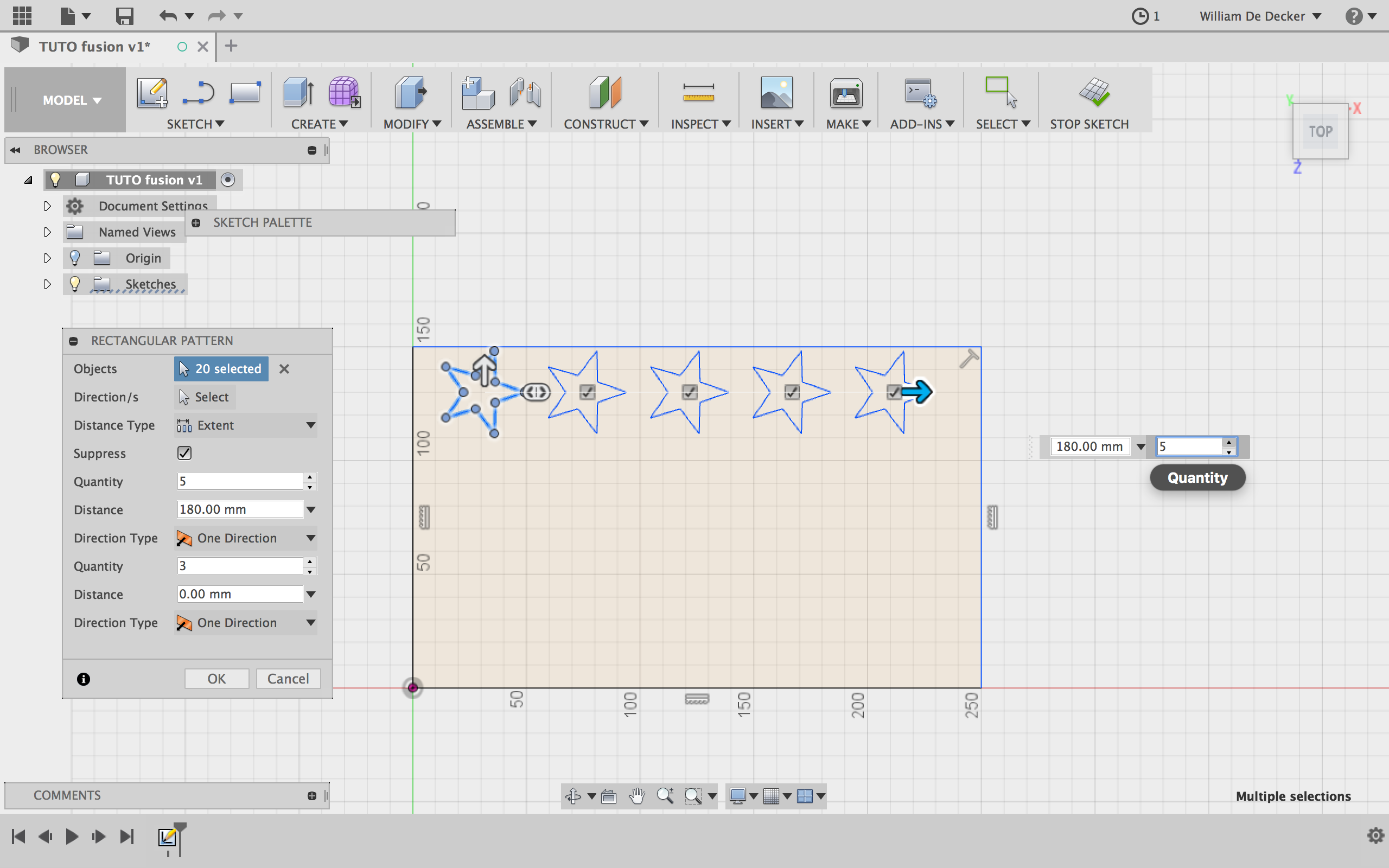

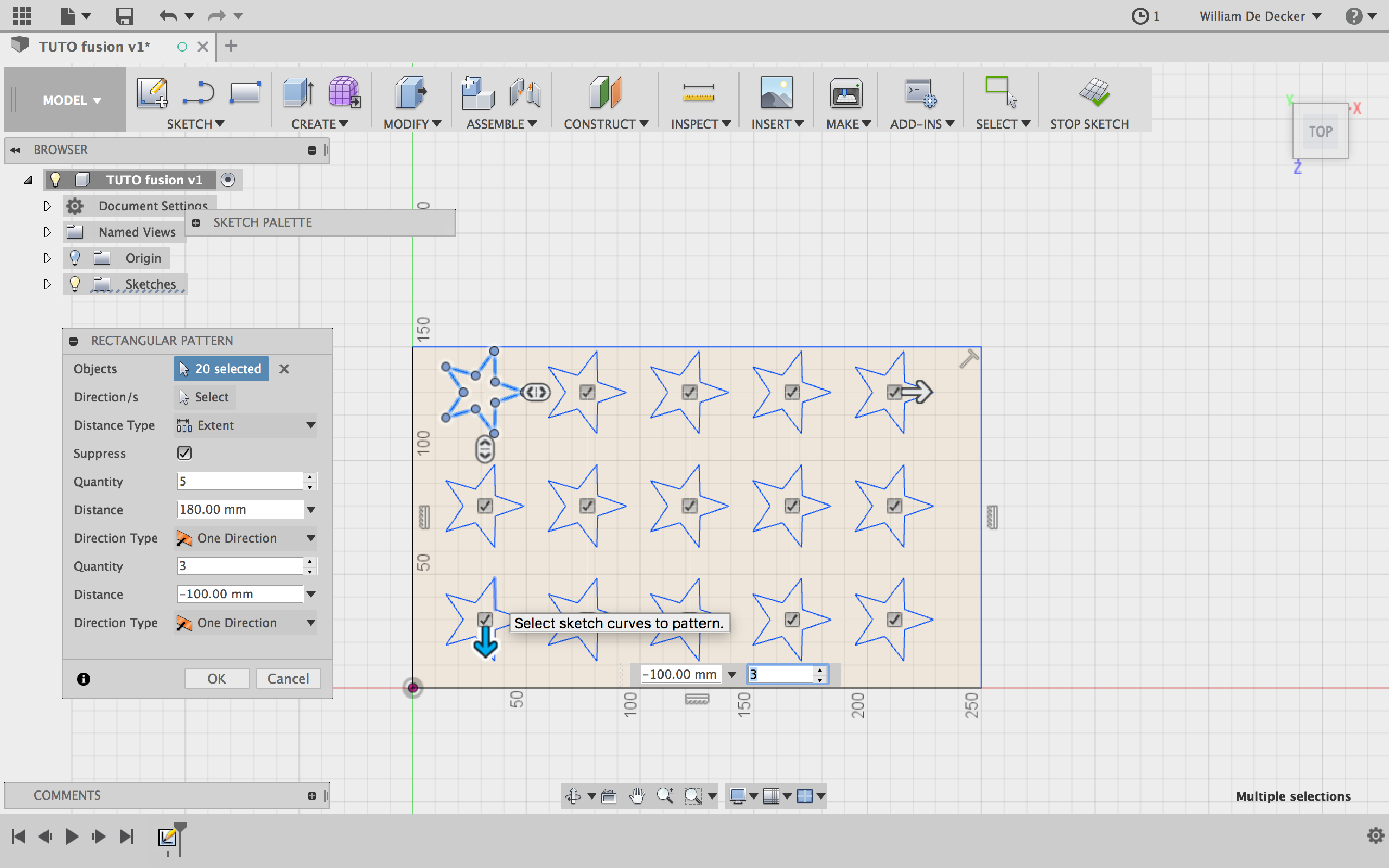

Rectangular pattern

To apply rectangular patterns, select the desired shape and the amount of copies you want in the 2 directions. You can then enter (or drag-drop) the distance on which you want to copy that shape for both directions and click "ok".

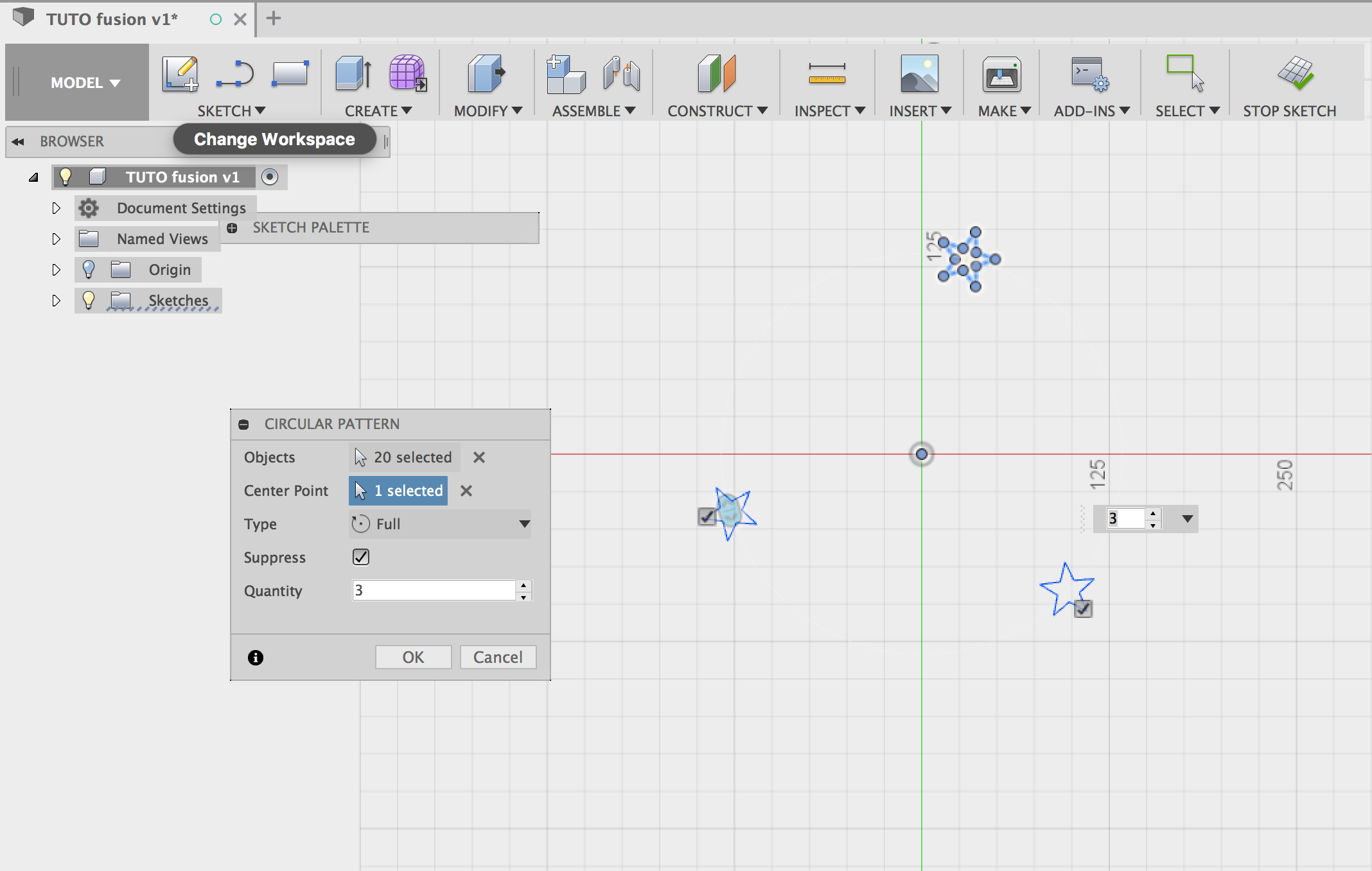

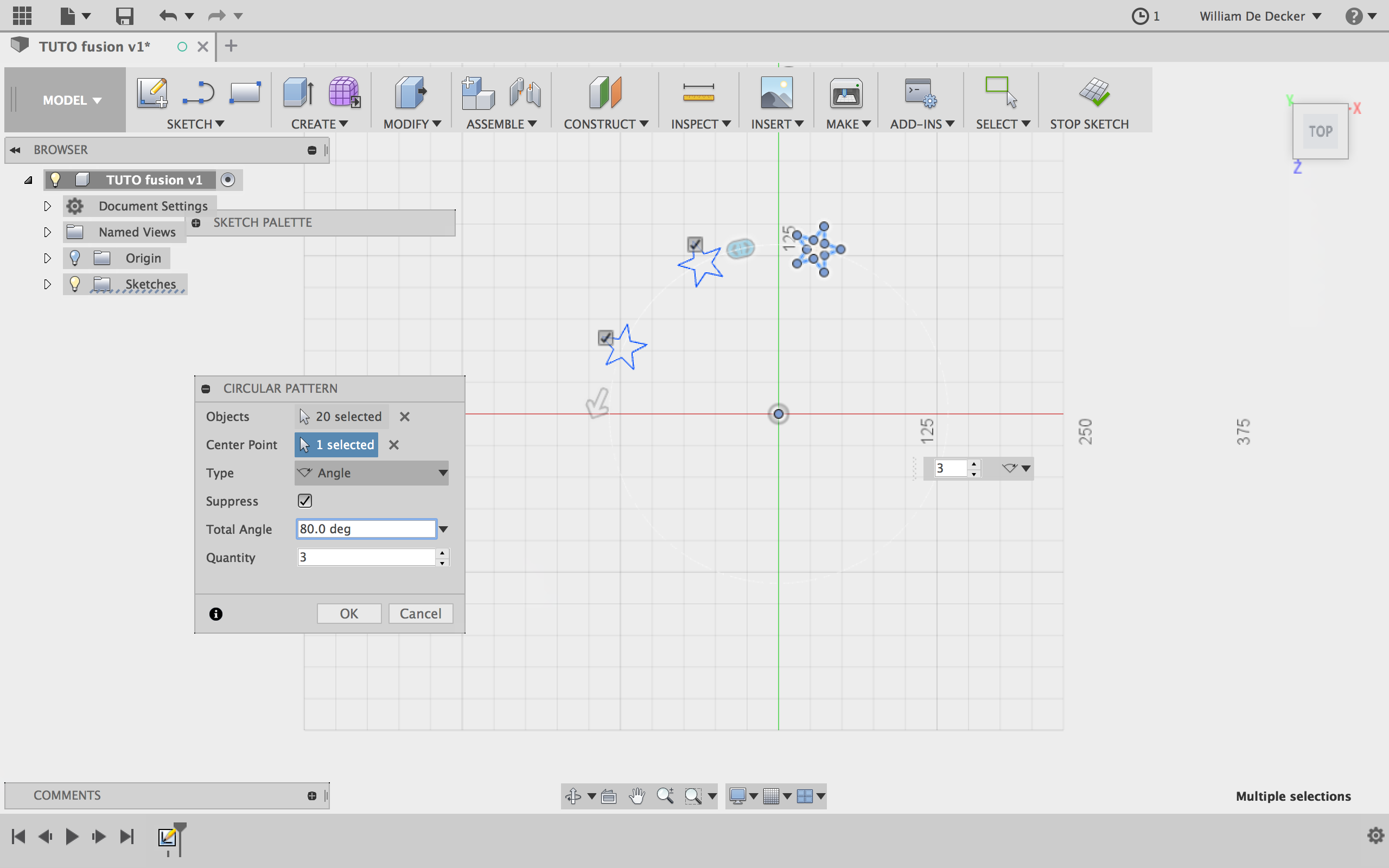

Circular pattern

Circular patterns work in a similar way accept the fact you have to choose a center point and you can choose to make a complete revolution around it, or on a given angle.

Note that it's also possible to draw a path and then follow it with our pattern.

Mirror

Available in sketch and also in 3D, the "Mirror" tool is very useful to create quickly twice the same things symmetrically from a line or a plane.

For the 3D tools, start by drawing your piece, in this case a notch to close a wall.

Use the Mirror tool, select the faces that you want to copy and then the plane.

Note that if you select only the top face of your notch you won't be able to copy it because the program doesn't allow you to create a new face in the empty space. You have to select all the three faces of your notch.

As we said, it's also available in sketch mode. So if you want to make two holes symmetrically. Just draw a circle. Draw a construction line that we'll use as our center line. Chose the distance from the center line, then select "Mirror". Select the circle as "Object" and in the "Mirror line" select the construction line

We can now make our two holes. Select the two of them (by holding "ctrl" pressed down) and then cut them through the bodie.

Fillet

As you used it in Autocad or similars, fillet allows you to joint two lines to make a curve.

In Fusion 360, as a 3D software, you'll also find the possibility to "curve" your 3D body.

To use the sketch fillet, just select it and then click on the two lines to join.

In the 3D model, just select the edge and with the arrow or value chose the radius of your fillet.

Chamfer

In the same way of thinking than for fillet, you'll have the possibility to make a chamfer.

Select the tools and click on the edge.

You'll also be able to do it with a curved edge (the one made with fillet)

Note that in this case you'll be limited by the angle of the previous made fillet.

Another option is to change the "Chamfer type" and select "Distance and angle" to make a chamfer with a selected angle.

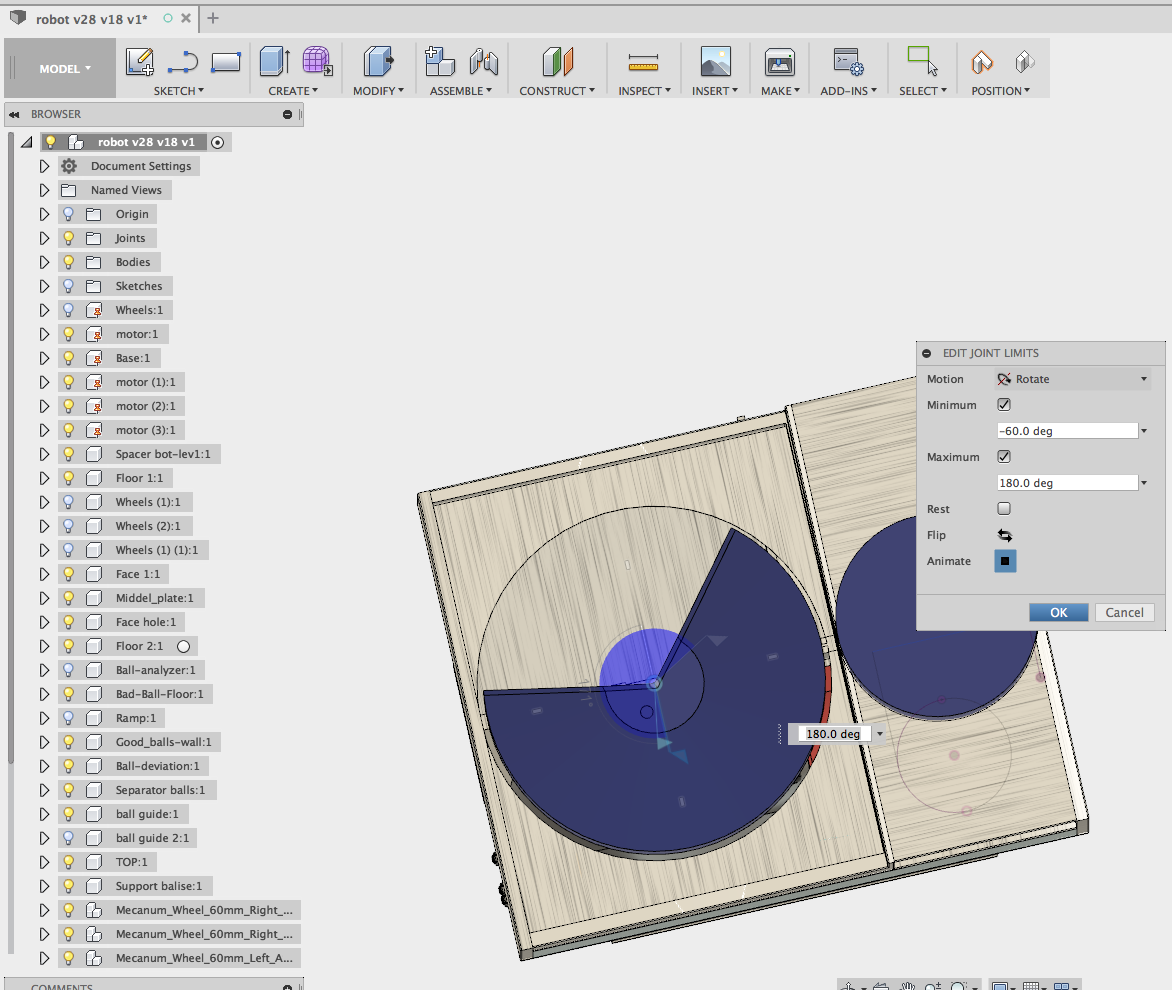

Join

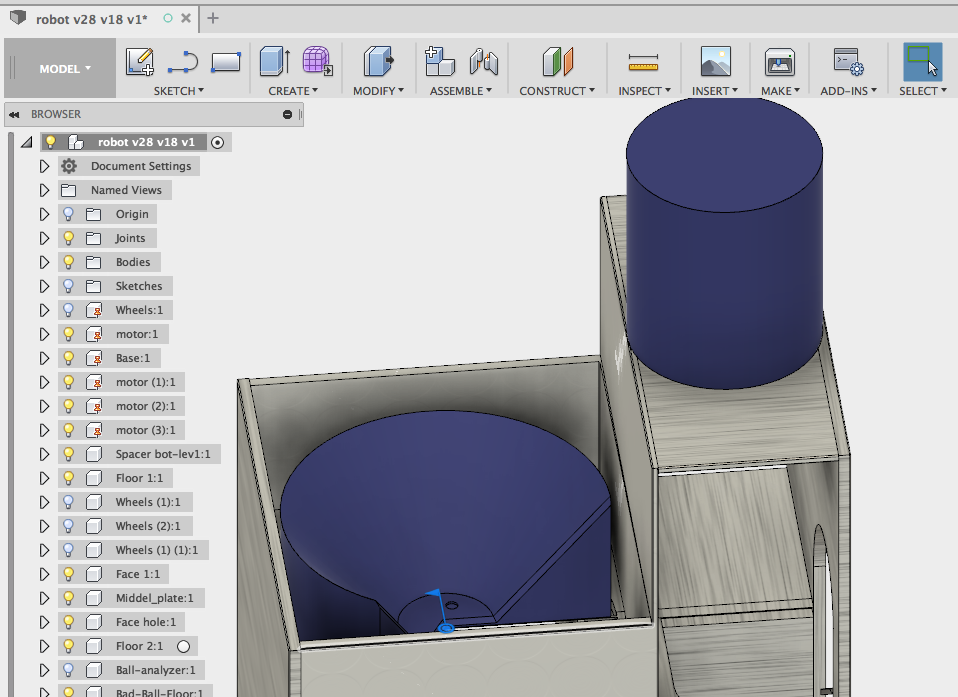

A joint is a link between two pieces that describes the way they move one on the other. It comes in handy when describing actions to external people, or when modeling pieces in an assembly to avoid collisions due to design mistakes.

To create joints, you have to first ground components. By grounding components you avoid them to move, and so you can use them as a static reference. Take Cortex for example, the base has been grounded and all the rest around him has been jointed.

This means you can not drag it around. The second thing you have to do is create rigid groups. By searching for "rigid group" when hitting the "s" key you will enter the "rigid group" menu. You can now select all the component that should move together. You'll still be able to drag them around, but only as one group and not separately anymore. This is for example the case for the mecanum wheels as you can not move their different pieces separately.

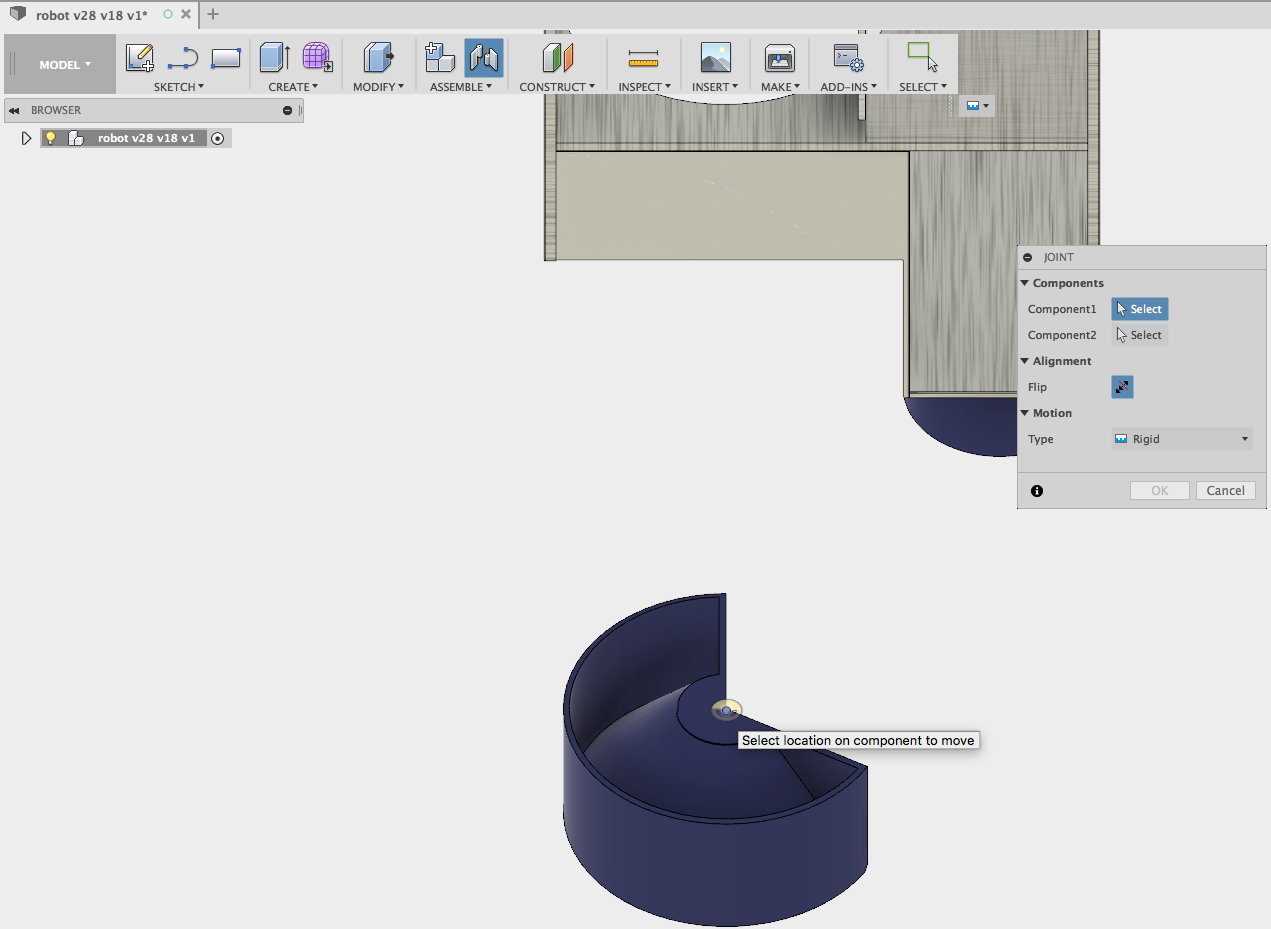

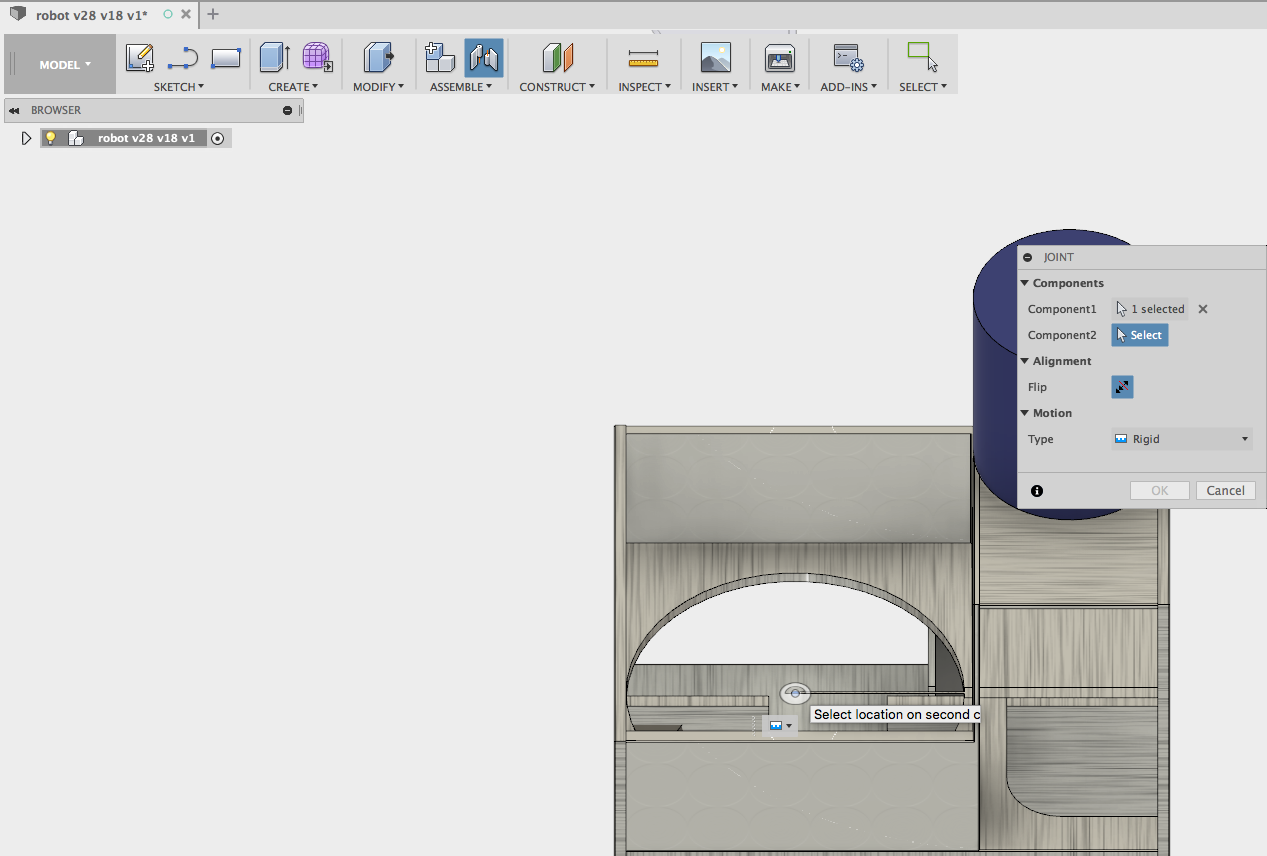

After this is done, we can now join modules together ('j' key). To do so select the points of the modules that will touch after jointing starting with the one you want to be able to move.

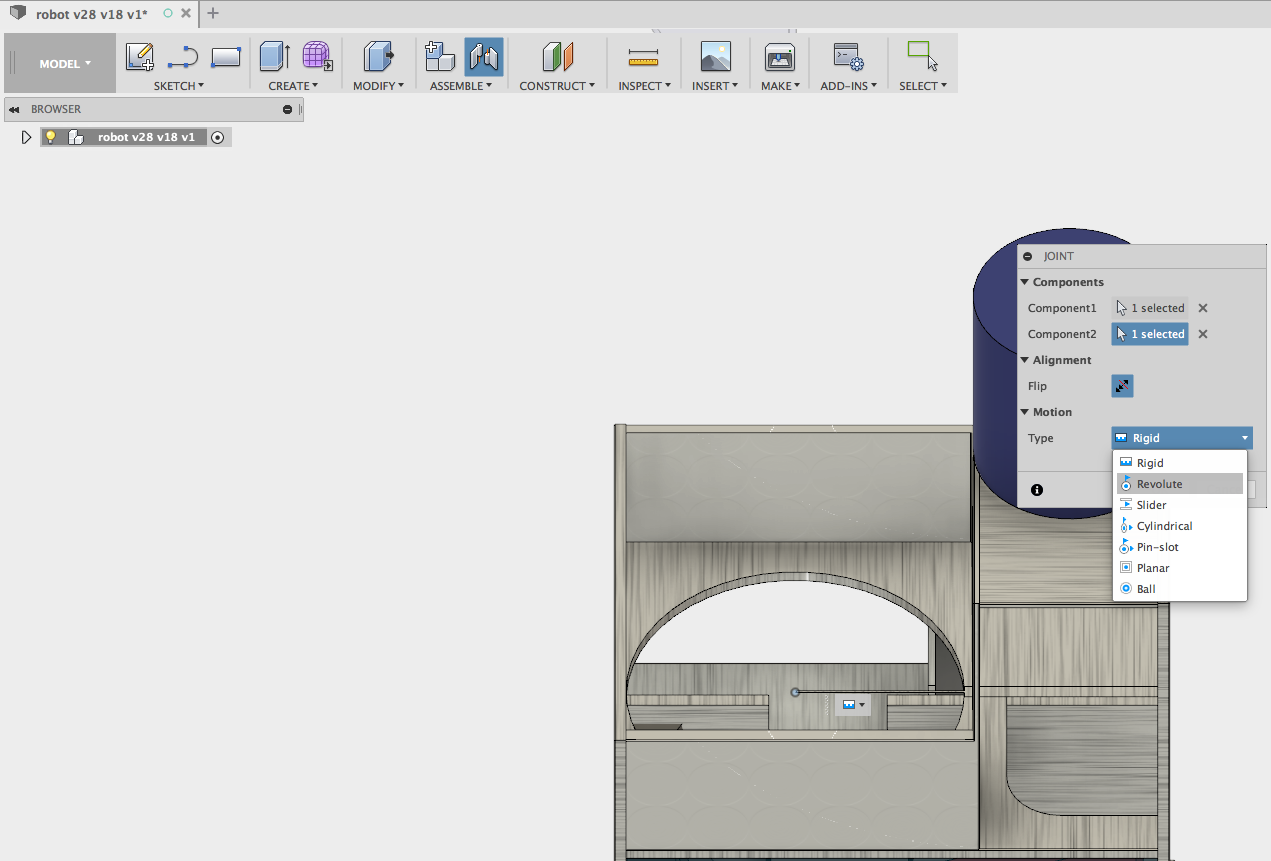

After this is done you can select the type of joint you want and the axis along which to movement will have to be.

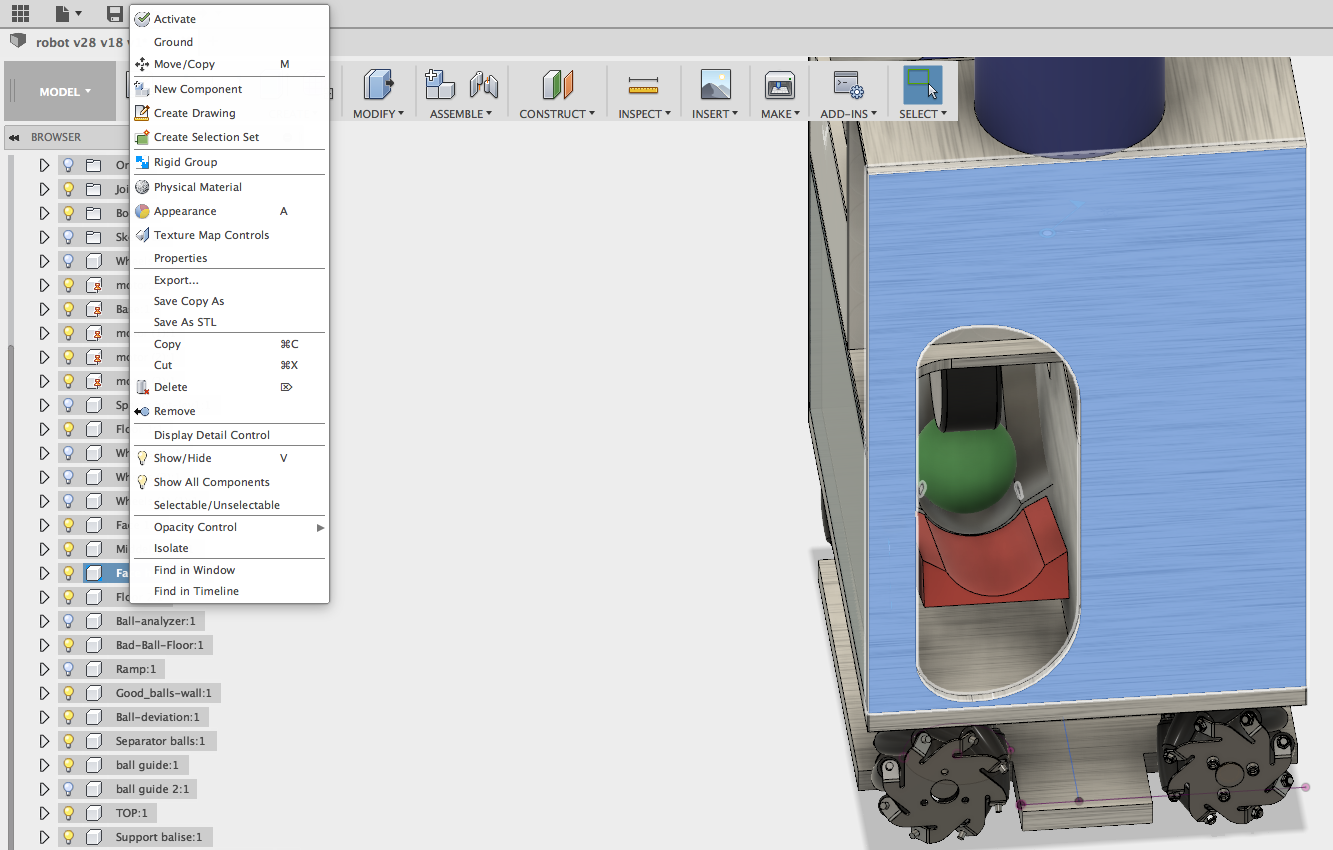

After confirming the settings, you can right-click on the joint to edit the joints limits and inverse the natural movement.

To learn more about jointing component click on the link to Lars's video about that topic Fusion 360 Tutorial — How to get a handle on Assembly and Joints in Fusion.

3. 3D Design export to plan or 3D Slicer

3.1. Design export as drawing

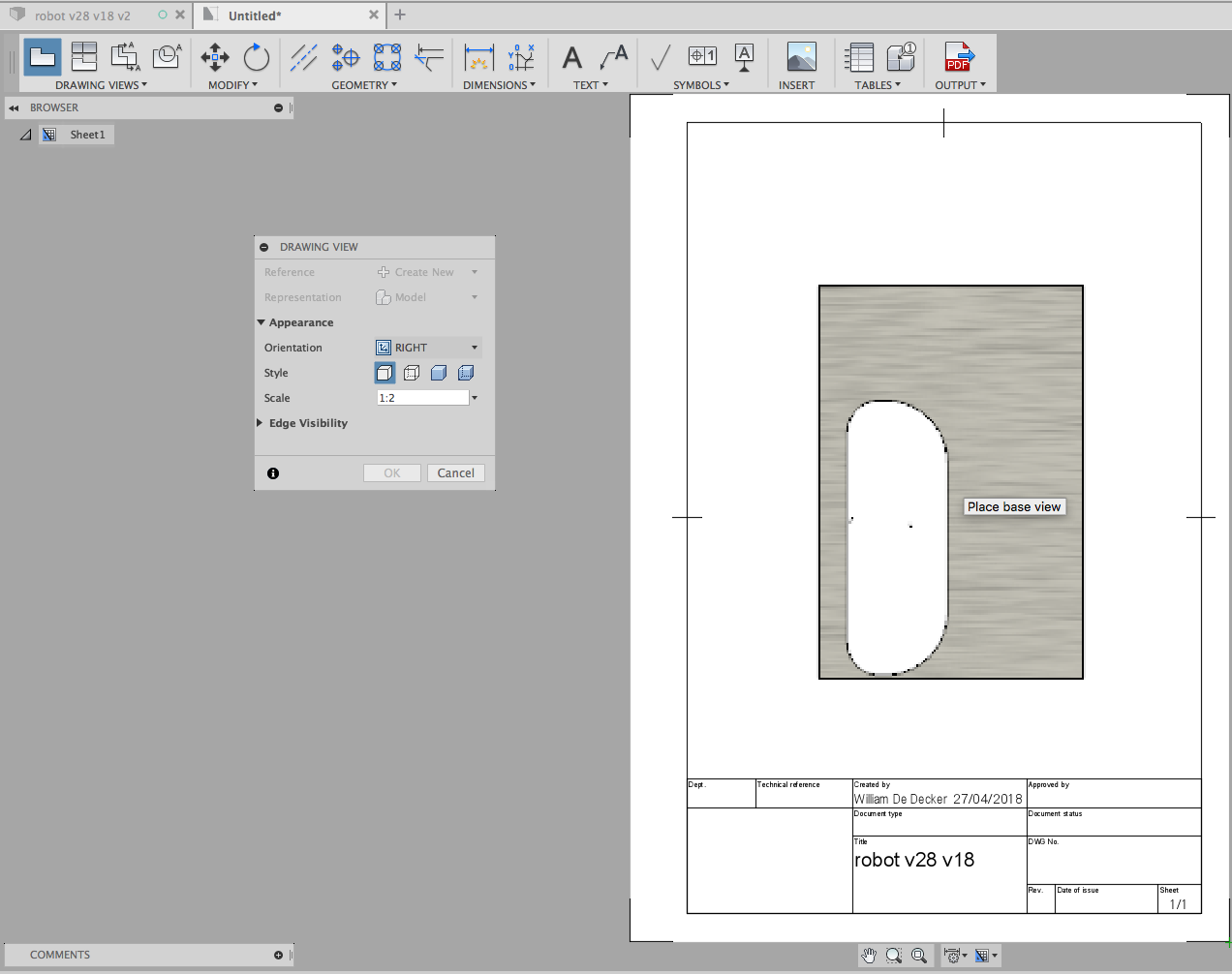

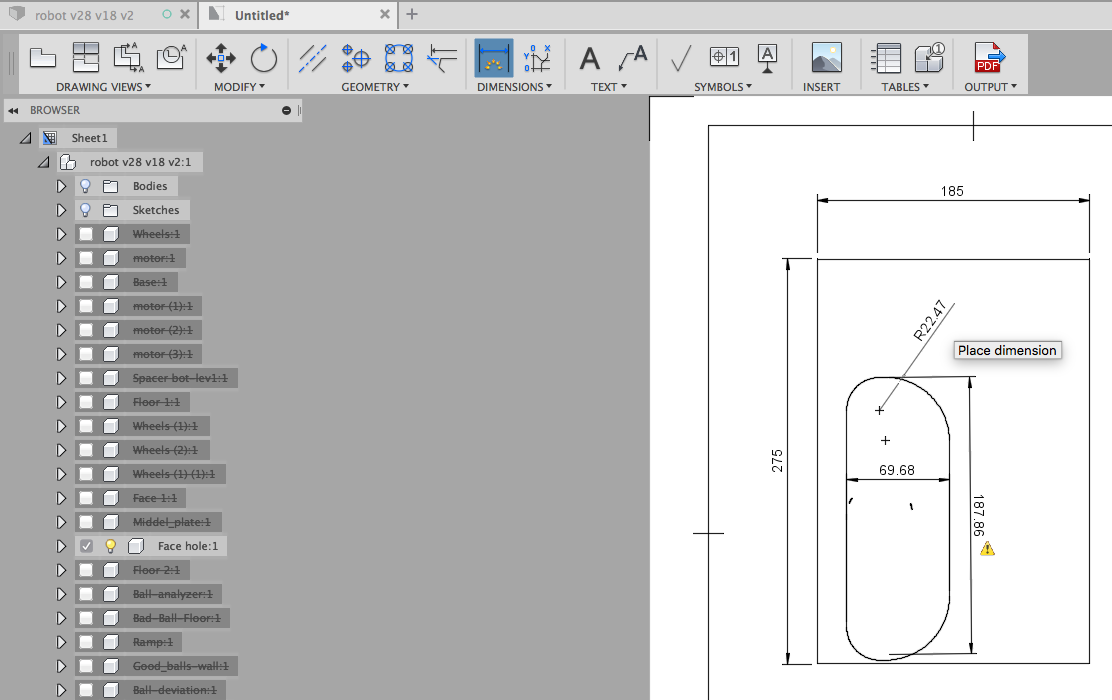

One of the main reason you have to make a 3D model before starting the actual build of your project is the ease you get to make 2D plan you can send to a manufacture or use to build the pieces your own. Making this plans will save you a lot of time and material because all the testing on designs is made virtually and not with physical materials you have to buy, cut, test, re-cut , etc... To extract the plans of the design you made, right-click on the component you want and select "create drawing".

A window pops up to specify the parts you want to include in the drawing and the format of the destination sheet (be careful on that) select the piece and click "ok".

A widget is automatically created and the component is now attached to your mouse. Notice that in the small window that comes with the widget you can select the view and scale you want to use. After dropping the component and clicking "ok" on the small window your drawing is fully generated and you can start editing it.

By hitting the "d" key you can start indicating the dimensions you want to specify. Save to PDF and your done.

3.2. Export 3D design (3D printing)

Now comes the fun part: 3D printing your own designs. You'll see that it is really satisfying to see something you designed your own "come to live" in the printer and to do so you will have to export you design as an '.stl' file.

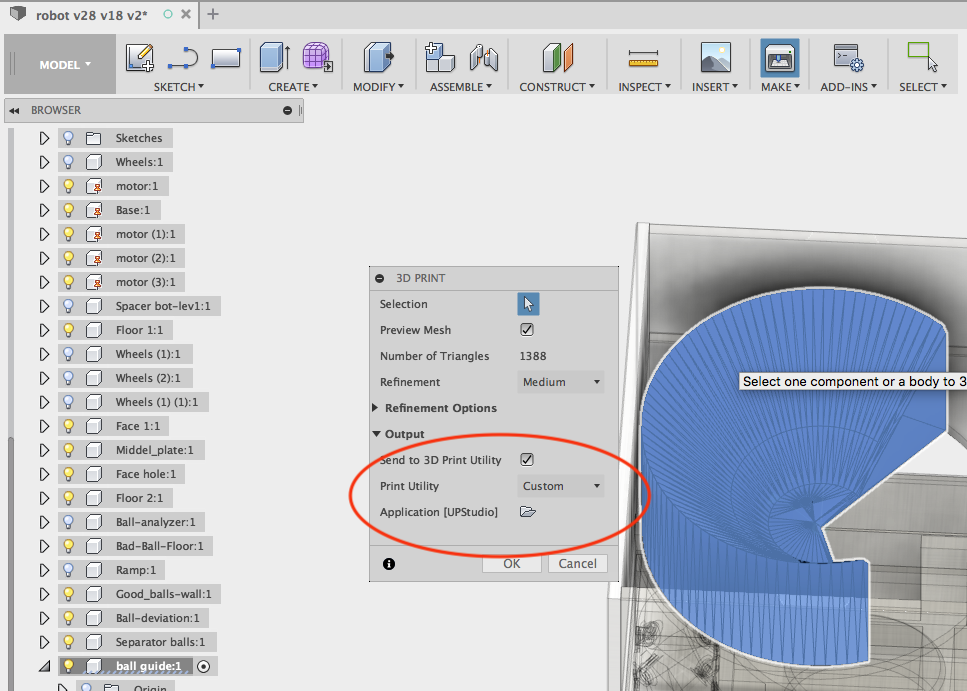

First start by hitting the "make" icon in the top bar.

![]()

It will open a window asking you to select the component you want to print and where you want to send the stl file. As you might expect you have to click on the body or component you want to print (One at the time!). As most printers have an accuracy only as good as their nozzle diameter, an assembly will always be printed as one bloc! For that reason we recommend to only select bodies when printing an assembly. It takes more time to print, but if the pieces have to move their is no other way to avoid monolithic prints.

Now comes the moment you have to choose between sending your design to a facility (and generating an stl file) or printing it from your computer and send it to a slicer software (up studio for the small printer in ECAM's electronic lab, Ultimaker Cura, Repetier-host, etc...).

To create an stl file unselect "Send to 3D print utility" and select ok.

To 3D print it from your computer select "Send to 3D print utility" and link your slicer software by clicking on the folder icon. When the slicer is linked click "ok" and launch the print form your slicer that will have been open and loaded with the design by Fusion360.

4. Design import and modification

As you probably know there are tons of CAD drawings already made that can often help you in your designs. You'll find them on different formats but in general, all of them can be open with fusion or a slicer to print them.

The best known databases are:

In GrabCAD, you'll find .stp, .sta, .SLDPRT files that you'll have to send into fusion to modify them and then send them in your slicer. You'll find really useful and complex design to add to yours to verify dimension and so on. We used it for example for our Home Automation Panel during the 2018 Edition, where the design of the LCD, the Arduino and the motor really helped us to fix the dimensions of the panel.

When you'll have the file that you want to implement in Fusion, just click on the upload button (top-left corner, on the project panel).

Always use this method instead of opening the file with fusion directly or it will make errors during the conversion

You now have the possibility to link these new designs into yours. Just open the main design to see it, right-click on the secondary design and "Insert Into Current Design". The now linked component will be shown with some chain link on it.

In Thingiverse, you'll find .stl files, already thought for the 3D printing, with some tips on how to print them sometimes.

It's also possible to modify them with the following steps.

Contributors

- Puissant Baeyens Victor, 12098, MisterTarock

- De Decker William, 14130, WilliamHdd

1. How to think 3D printing

Now that you know how to design in 3D and export your file to a slicer, we'll take you straight to the world of the 3D printing. We'll see his amazing abilities but also his limitations.

1.1. Think "mechanical properties"

When you'll have to create a mechanical piece for your robot, you have to think about the way you'll use it. For example, if it's a piece that will be in contact with water, a lot of people will have the tendency to say: "You have to use ABS!" Right now there are other possibilities as the PETG that have similar properties but has less warping. Each one of them have their advantages and their defaults. It's true that the ABS will have better mechanical resistance against wear and tear than PLA but you'll have to pay more attention at the temperature variation and the wrapping problems. That's only the top of the iceberg for the materials, if you're interested by knowing more about it, you can still find a lot on the web on divers site like: Primant3D.

Another simple tip is to think about the way the fibers during the use of the pieces.

As you can see on this piece, a Pelton wheel , at first the shaft and the wheel were design as in one piece.

After thought, as the shaft will have to oppose strength in the radial way, it's way more efficient to print it horizontaly than verticaly (where the layers would detache).

For the wheel, it's the opposite. The spoons have to go against strength in the perpendicular way, so it had to be printed also horizontal, laying on the bed.

It was then decided to print them in two pieces.

1.2. Think about the supports

As you'll see in the point 3. Printer Configuration, there are a lot of different parameters to take into account. In this point, we'll speak about the supports, their necessity and their troubles.

As you can see on the picture below, there a lots of support placed to help the printer. As the print is done layer by layer, it needs supports to help the extrusion of part on empty space.

Note that you'll have to be in layer view to see them (Top-Right Corner)

The most used to tune your print is the Overhang Angle, it will allow you to control the amount and place of the supports.

The use of limiting the amount of support is to reduce waste, reduce printing time (in this case 1h45) but also cleaning time as you'll have to cut or tear them apart by hand. There is a possibility with dual extrusion to print them with PVA (water soluble filament) but it requires a more expensive printer.

However, I recommend to try the parameters shown on the picture because they make the removing of supports way easier than the default one.

1.3. Think about the face laying on the heat bed

As said before, the printer will often need support, but the orientation of the piece on the bed will also help a lot to reduce them.

In this piece, simply by laying it on one face, you'll remove all the need for support.

In this case, it would be absurd to put it on the other face as it will require a lot of support and their will be very complex to remove.

On this final picture, imagine many of this cubes needing to be plugged one in another and that have to be printed on their left face. You can use two different design:

- In the first design (the two top cube) the top-left one will require support.

- In the second design (the two cube below) the low-left one can be printed easily.

More, in the second design, all the cube are the same so you can print a lot of them really fast.

2. What printer to choose?

The offer in mater of 3D printers is enormous and can be confusing to an unexperimented printer. And even if you know what you are looking for, you can find the same looking printer for at least 10 different prices and brands. As a matter of fact a lot of companies copy the "big ones" and sale these copies a lot cheaper. These copies can be a very good investment for non-professional work and can save you quite a few euros, but can also be a real nightmare.

A general advice is to read as many reviews as possible and to try to choses a printer that a lot of people have. Isolated brands are often isolated for a very good reason (quality issues for example) and you'll struggle finding informations on settings, performances and things like parts to print to upgrade you printer.

The Anet company for example is very popular brand that sells versions of open source printers. The are close to the cheapest you can find, but have very decent quality and high liability. Hereby lots of people have one and you can find tones of parts on Thingiverse AnetA8 to upgrade their models.

Other companies like FLSUN sale some of the same open source models (prusa i3) a like more expensive but are less reliable and upgrade parts are pretty difficult to find.

So what to chose ?

Well we are not going to give you a list of printers to buy or not to buy, but we'll try to give you guidelines to follow when comparing what the market offers.

2.1. Technologies

Men have developed different ways to 3D print stuff, each and every one of it with its own advantages. The cheapest and thus most used is the extrusion of molten plastic, but others like resin printing (where a laser hits a bath of liquid resin hardening it instantly) or metal printing (same idea as for resin but with a bath of metal powder), are starting to emerge. These however are really expensive (2 000$ up to hundreds of thousands of dollars for the machine only) for the moment and won't be discussed any further.

The rest of this document will so only speak about plastic extrusion printing.

2.2. Structure of the printer

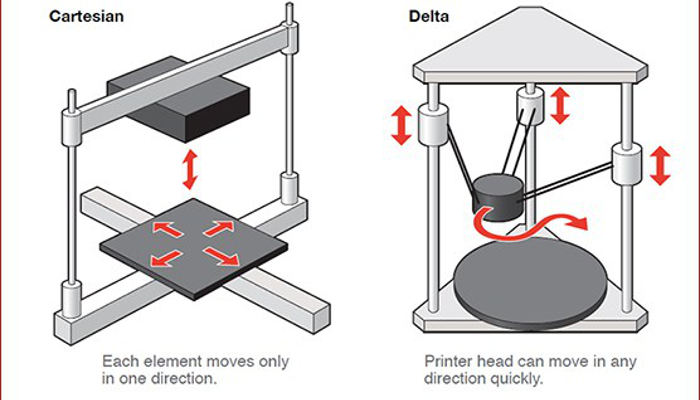

You'll find two main types of structures: cartesian and delta.

Delta 3D printers were designed for speed, but they also have the distinction to have a print bed that never moves, which may come in handy for certain print jobs. In the other hand, their speed comes with a certain weakness for details and a lack in precision.

Cartesian printers are better for details and easier to build and maintain, but slower.

2.3. Precision

As you might expect, cheap printers (100€-400€) don't have the same accuracy as semi-professional ones that cost about 2000€-5000€ (Ultimakers for example). This can be scaring at first, but think about it this way: do you really need to print at a resolution of 20 microns (an aluminum sheet is about 16 microns )? For most of the prints you'll make a precision of 0,2mm and a little bit of sanding is more than enough. You can find more than decent printers for around 200€ (Anet A6) for medium bed sizes. Larger bed printers will cost about 300€ (Creality3D CR - 10). Note that these printers are DIY printers so you'll have to assemble them your own. This might take a few days, but is a piece of cake with the manual and will save you a few hundred euros.

2.4. Links

To close the subject, here are some links you could find handy in your search of a 3Dprinter to acquire or to improve.

- Thingiverse AnetA8

- Instructables improvement

- Choose between a Bowden or Direct extruder

- Anet A8 vs A6

- Anet A8 improvement

3. Printer Configuration

There are tons of different parameters that will influence the quality of your print. It would be out of the topic to list them all but we encourage you to read the following document to calibrate your printer as good as possible.

4. Some tips before printing

The Ultimaker 2+ is the printer that we are using for our 3D model. Before using the printer, there are some points to check :

- The filament

- Is it a PLA ?

- Is it a 2.85 mm width ?

- Isn’t it stuck ?

- Is it in the right position?

- The build plate

- Placement, adjust it accordingly (follow the instructions on the printer)

- They may have some adherence issues, the trick is to use glue on the plate

When you lunch the printing, always wait for the 1 layer before leaving, it may have some adjustment error or filament can be stuck.

Troubleshooting

If the filament is stuck, it doesn't come out, stop the printing.

It may happen because :

- The filament is stuck and it can't feed the printer

- The nozzle is clogged

If the nozzle is clogged try the Atomic solution

Else try https://ultimaker.com/en/resources/11704-extrusion-problems

Contributors

- Puissant Baeyens Victor, 12098, MisterTarock

- De Decker William, 14130, WilliamHdd

- Ping Tian-sen 16333

Rules of good use of 360° merger

Make files for each part of the robot. Explicitly name the name of each folder If necessary, create a folder for electronic components, tags,.....

Make each part of each part independently to have a faster modification later on.

Give an explicit name for each part in order to be readable by everyone who would like to consult the hub. Try to keep the same name of every same parts, like right panel, right side,…

Make an assembly with all the parts drawn and make an overall drawing. Do not forget to create rigid groups and joints to make it easier to place the parts. The advantage is that when we modify a part included in the set, the assembly will be updated with the new dimensions of the part.

Assemble all the assemblies to finish the robot drawings. Once again, the assemblies will be updated as they are modified

Mecanum wheels

A mecanum wheel is a wheel with rollers attached at its circumference at an angle of typically 45°. When four mecanum wheels are used together, we can achieve a net resulting direction in any direction by varying the direction and speed of rotation of the wheels.

Assembly

Wheel adapter

To mount the wheels onto the motors, we need to use an adapter. Due to an error in our order, we didn't receive the correct adapters and the ones we received didn't fit on the wheels.

We decided to 3D print our own as a replacement. The STL file for this part can be found here.

Note:

3D printing parts that will be under moderate or heavy mechanical stress is often not the best idea, because those parts will tend to break and/or wear out quickly.

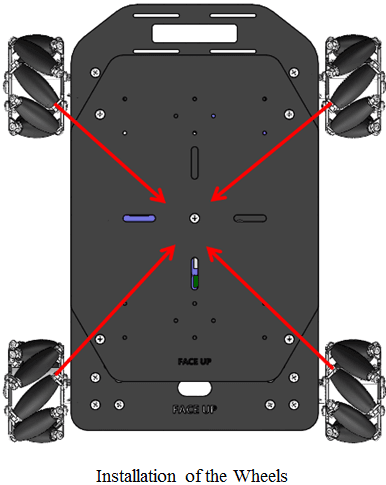

Wheel orientation

When assembling the wheels onto the robot, we need to pay attention to their orientation. If we look from the top view, the rollers should all point to the center of the base.

Kinematics

Forward kinematics refers to the use of the kinematic equations of a robot to compute the position of the end-effector from specified values for the joint parameters. In our case, the forward kinematics allow us to compute the global velocity of the robots base when given the angular velocities of the individual wheels.

The reverse process that computes the joint parameters that achieve a specified position of the end-effector is known as inverse kinematics. The inverse kinematic equations allow us, in our case, to compute the individual wheel velocities needed to achieve a given base velocity.

The equations presented in the next sections come from the following research paper: "Kinematic Model of a Four Mecanum Wheeled Mobile Robot"

Inverse kinematics

The inverse kinematic equations allow us to compute the indiviual wheel velocities when we want to achieve an overall base velocity.

- \(\omega_{fl}\), \(\omega_{fr}\), \(\omega_{rl}\) and \(\omega_{rr}\) represent the angular velocities for the front left, front right, rear left and rear right wheel respectively.

- \(v_x\) and \(v_y\) represent the robot's base linear velocity in the x and y direction respectively. The x direction is in front of the robot.

- \(\omega_z\) is angular velocity of the robot's base around the z-axis.

- \(l_x\) and \(l_y\) represent the distance from the robot's center to the wheels projected on the x and y axis respectively.

Or in matrix form:

\[ \begin{bmatrix} \omega_{fl} \\ \omega_{fr}\\ \omega_{rl}\\ \omega_{rr} \end{bmatrix} = \frac{1}{r} \begin{bmatrix} 1 & -1 & -(l_x + l_y) \\ 1 & 1 & (l_x + l_y) \\ 1 & 1 & -(l_x + l_y) \\ 1 & -1 & (l_x + l_y) \end{bmatrix} \begin{bmatrix} v_x\\ v_y\\ \omega_z \end{bmatrix} \]Example

If we want to let the robot move diagonally at 0.22 m/s in the x direction and 0.11 m/s in the y direction. At what speed should we set the motors of each wheel?

The robot is 15 cm in width and 20 cm in length. The wheels are placed at the extremities and have a diameter of 60 mm.

\[ \left\{\begin{matrix} \omega_{fl} &= \frac{1}{0.03} \left[0.22 - 0.11 - (0.2 + 0.15) \cdot 0 \right ] = 3.66 \; rad / s\\ \omega_{fr} &= \frac{1}{0.03} \left[0.22 + 0.11 + (0.2 + 0.15) \cdot 0 \right ] = 11 \; rad / s \\ \omega_{rl} &= \frac{1}{0.03} \left[0.22 + 0.11 - (0.2 + 0.15) \cdot 0 \right ] = 11 \; rad/s \\ \omega_{rr} &= \frac{1}{0.03} \left[0.22 - 0.11 + (0.2 + 0.15) \cdot 0 \right ] = 3.66 \; rad/s \end{matrix}\right. \]

Forward kinematics

The forward kinematic equations allow us to compute the robot's base velocity when given the individual wheel velocities. This is usefull to compute the robot's odometry using the motor's embedded quadrature encoders.

Odometry is the use of sensor data to estimate the change in position of the robot over time.

\[ \left\{\begin{matrix} v_x & = (\omega_{fl} + \omega_{fr} + \omega_{rl} + \omega_{rr}) \cdot \frac{r}{4}\\ v_y & = (-\omega_{fl} + \omega_{fr} + \omega_{rl} - \omega_{rr}) \cdot \frac{r}{4}\\ \omega_z & = (-\omega_{fl} + \omega_{fr} - \omega_{rl} + \omega_{rr}) \cdot \frac{r}{4(l_x + l_y)} \end{matrix}\right. \]Or in matrix form:

\[ \begin{bmatrix} v_x\\ v_y\\ \omega_z \end{bmatrix} = \frac{r}{4} \begin{bmatrix} 1 & 1 & 1 & 1\\ -1 & 1 & 1 & -1\\ -\frac{1}{(l_x+l_y)} & \frac{1}{(l_x+l_y)} & -\frac{1}{(l_x+l_y)} & \frac{1}{(l_x+l_y)} \end{bmatrix} \begin{bmatrix} \omega_{fl}\\ \omega_{fr}\\ \omega_{rl}\\ \omega_{rr} \end{bmatrix} \]Code

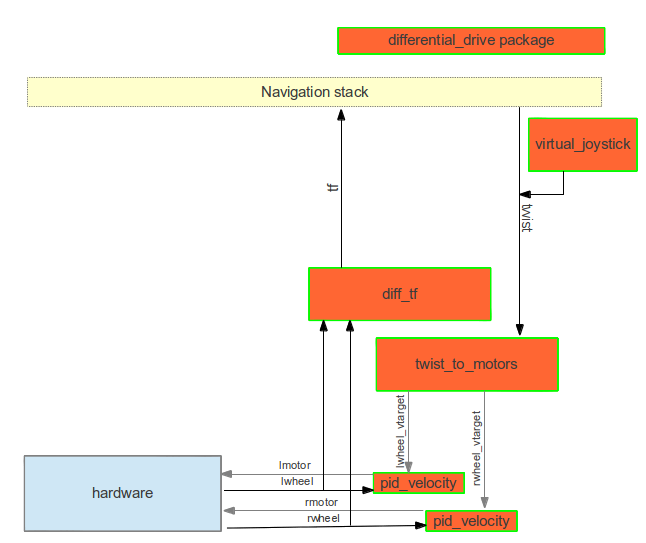

For an implementation of the mecanum wheels in the code, refer to chapter: Mecanum wheels in software

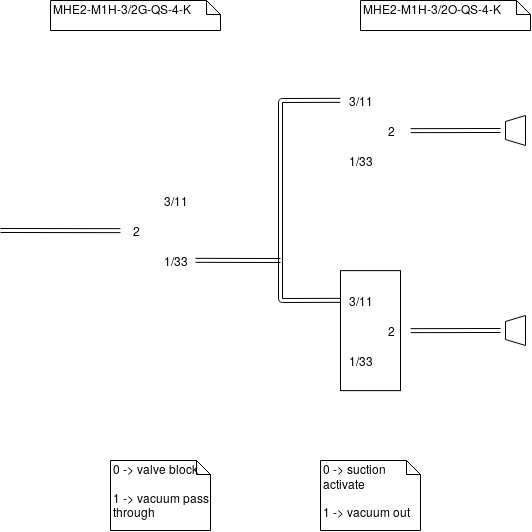

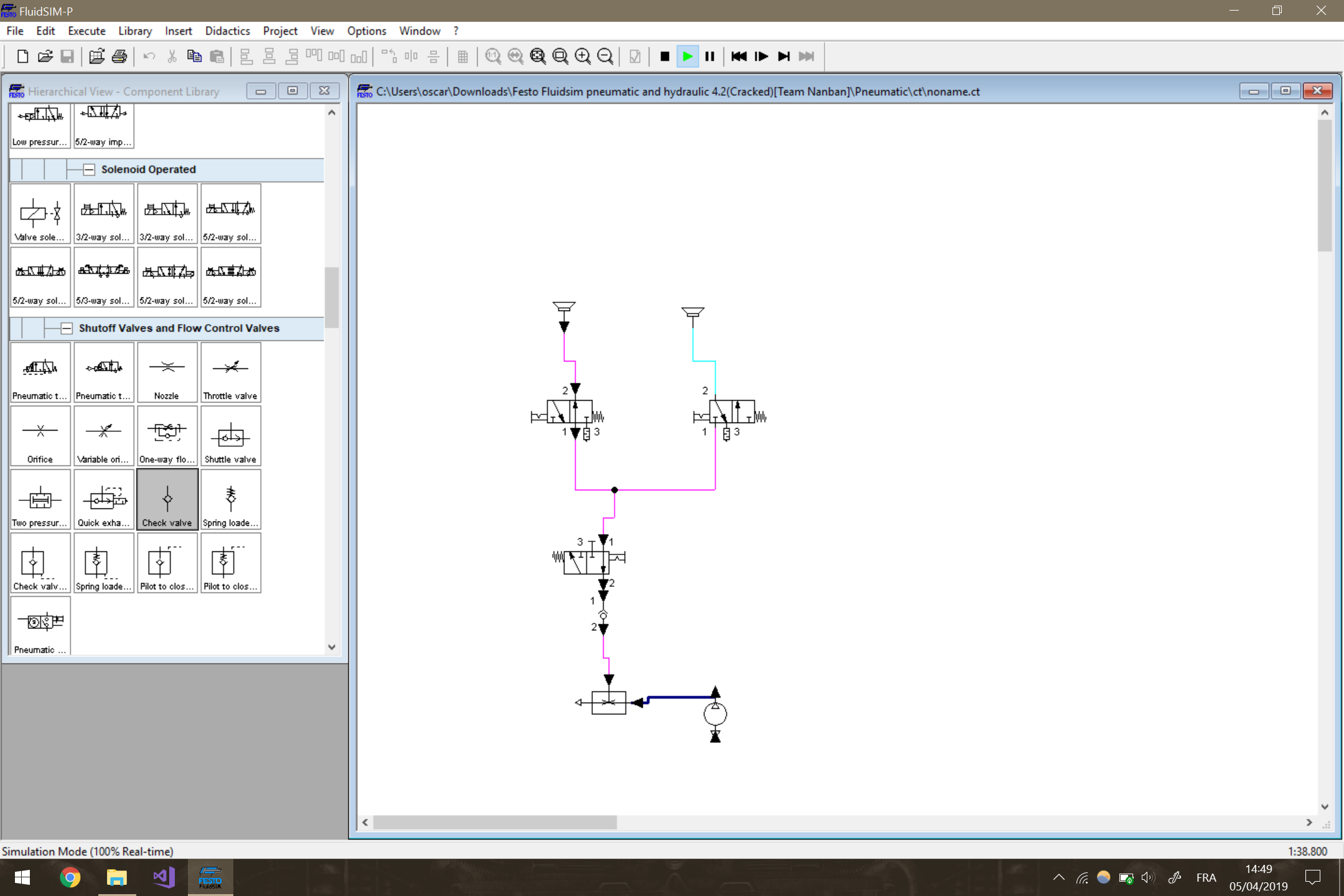

Vacuum prehention

To take the pucks, we use a vacuum system.

The material list:

- pump

- valve

- suction cup

The material is from Festo (we can have good price for student projetcs)

Other prehention systems were use to take the pucks of the 2019 contests: like shovel.

Pros

- mechanism is easy to take flat surface

Cons

- the pump use lot of power

- the pump and the valve take lot of space

2018 Specifics

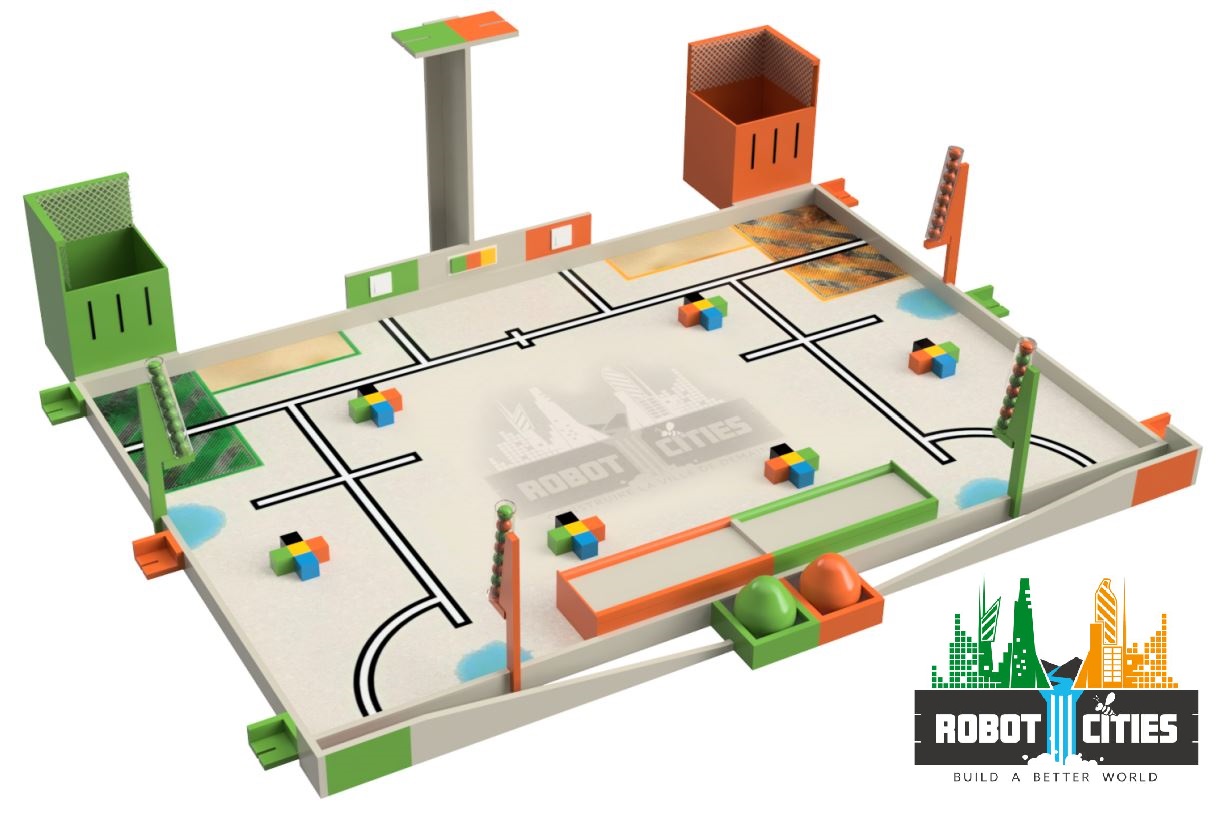

In 2018, the two big mechanical tasks were:

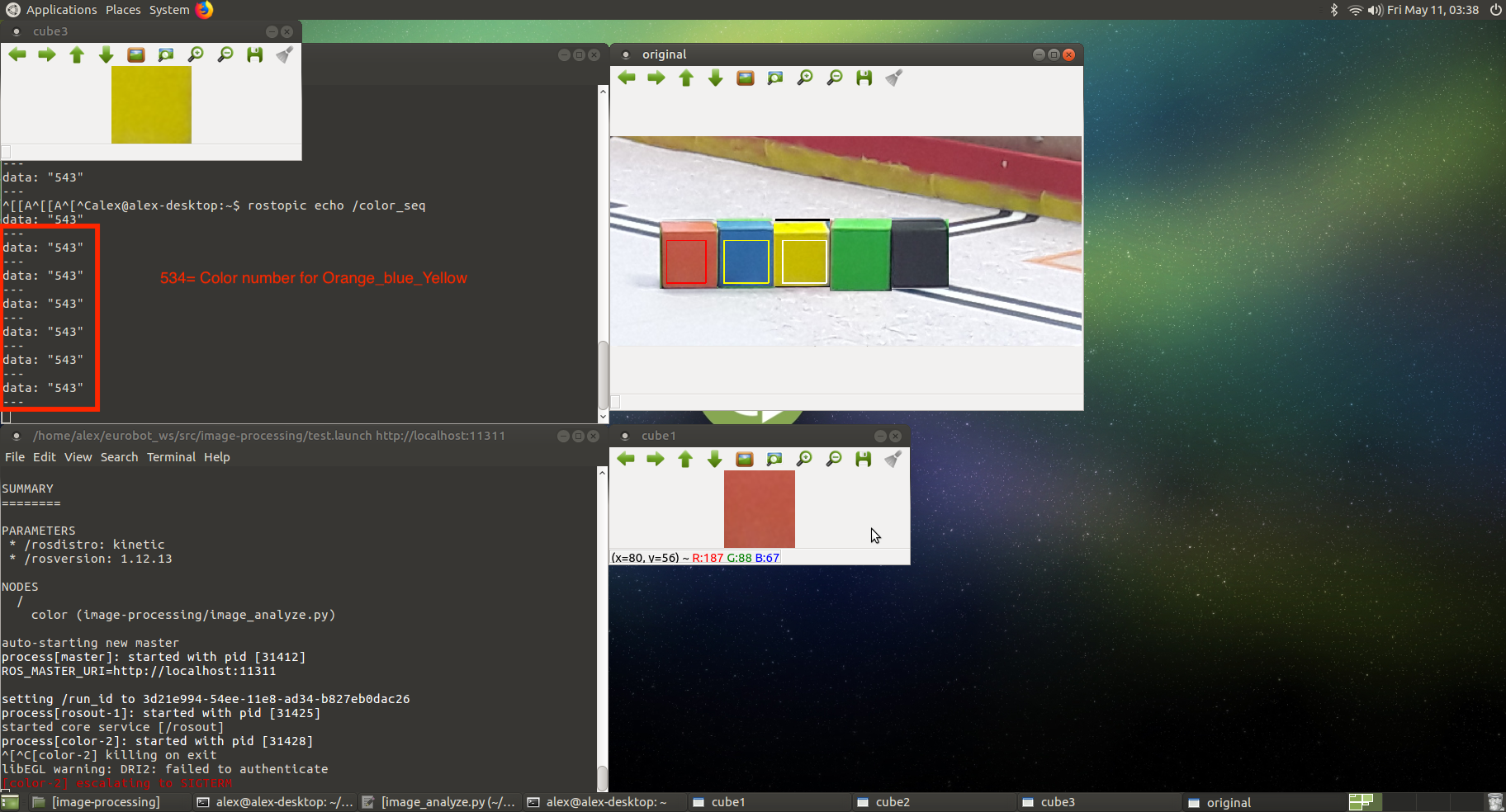

- Collect cubes that are distributed at specific locations on the playing field. The collected blocks then need to be stacked to create a tower. For each story (level), a bigger amount of points were given. Additionally, if the tower contained the 3 cube séquence, revealed at the beginning of the match, additionnal points were earned.

- Collect foam ping-pong balls from the dispensers. The robot first has to open the lock so that the balls can fall out of the dispenser. Then the robot had to sort the balls and, depending on their color, either shoot them into a "tower" or put them in another recipient.

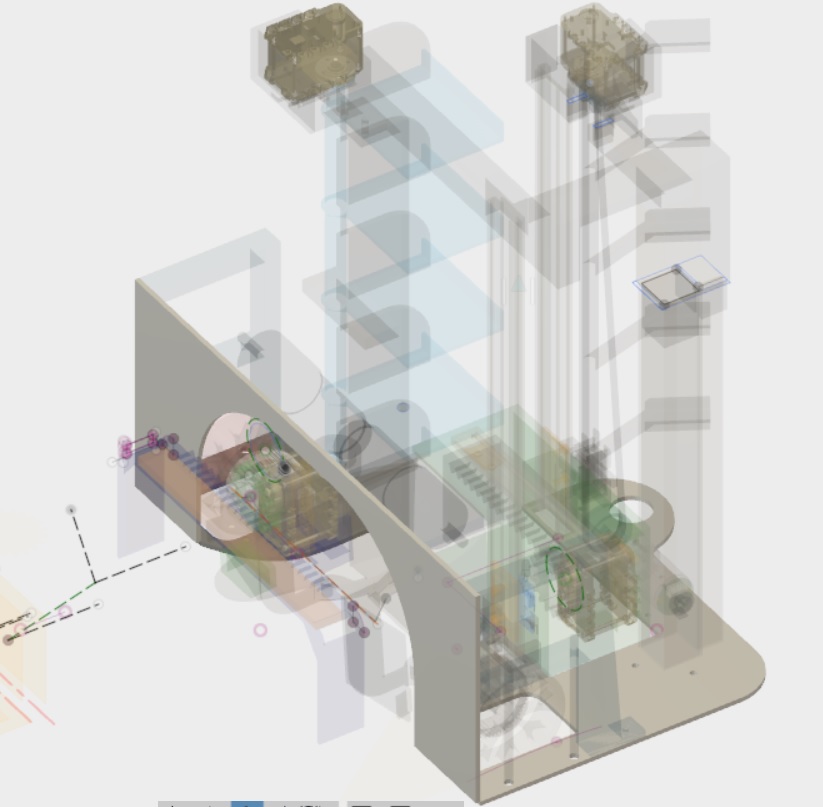

The big robot specifications

Fusion 360

The entire robot is designed in Fusion 360 and is available on the Eurobot cloud. The final version is called SHARK FINAL V17

Here is the link to download de fusion projet : BigRobotModel

The goal of the 2018 edition

The robot starts from the inital surface (number 1).

The robot has to collect the cubes and to build a tower of 5 cubes maximum in the construction zone (number 4). The team earns a lot a point if it respects the construction plan shown on the wall (number 7).

Sections ( How does it work ?)

This paragraph explains the differents conceptions's steps and all the parts needed to build a tower. Here is the general flow diagram :

The system doesn't need any color detection because all the stars of cubes are always in the same order in the same direction.

The base

This is the firt thing I'm going to talk about but it was the last designed part. Indeed, every part had to be designed to know the constraints and dimensions. Thoses informations where essentials to design the base.

After the design in Fusion 360 in the model environment, the design was imported to the CAM environment still in Fusion.

It was then machined with a CNC :

The entry

To swallow the cubes, an entry was designed. It uses simple DC motor with paint roller bought at the Brico.

The entry swallows the first 3 cubes and then select the fourth cube between the 2 last by pushing it with the toothed rack. After that the robot do the same step with the last cube. The rack moves with a rail available on RS component :

IGUS rail:

- Rail :Igus N Series, NS-01-17-300, Linear Guide Rail 17mm width 300mm length

- Carriage : Igus Linear Guide Carriage NW-02-17, N

To detect when the cube is in the lift, the robot uses a limit switch available on RS Component :

Limit switch : Snap Action Limit Switch, Roller Lever, Thermoplastic, NC, 125V.

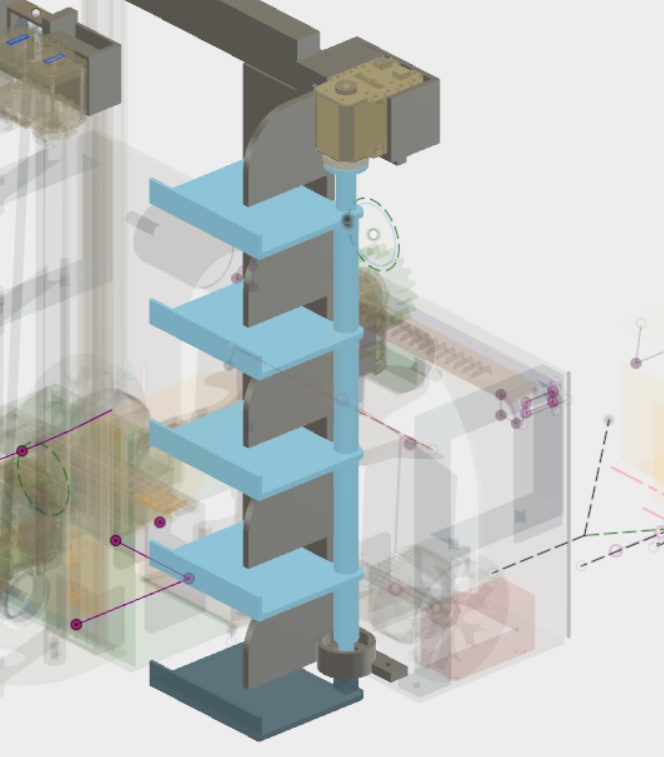

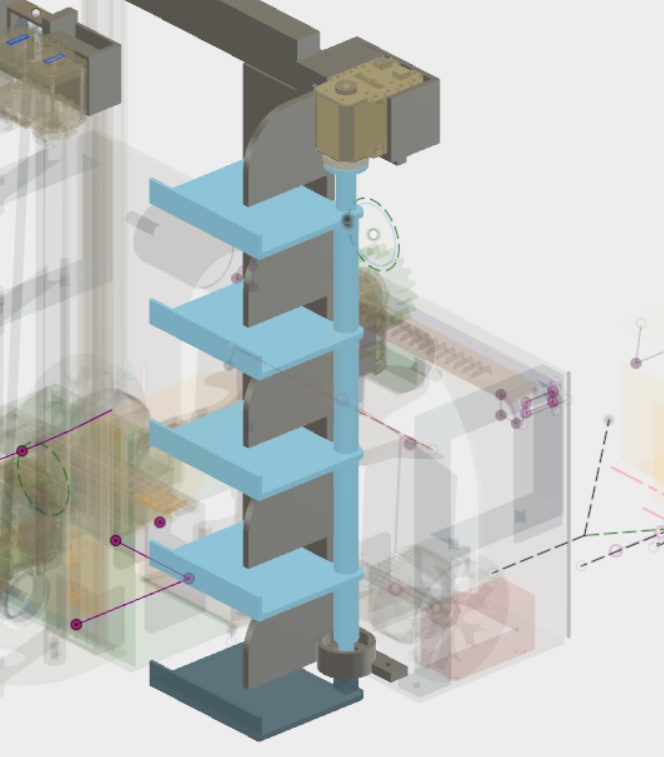

The lift

The limit switch used in the entry is connected to a pin of an Arduino Uno board so we can detect the state change when a block touches the switch. That event triggers the lift and thus the block starts to raise up. Therefore we are using another DC motor with a belt as you can see on the picture below.

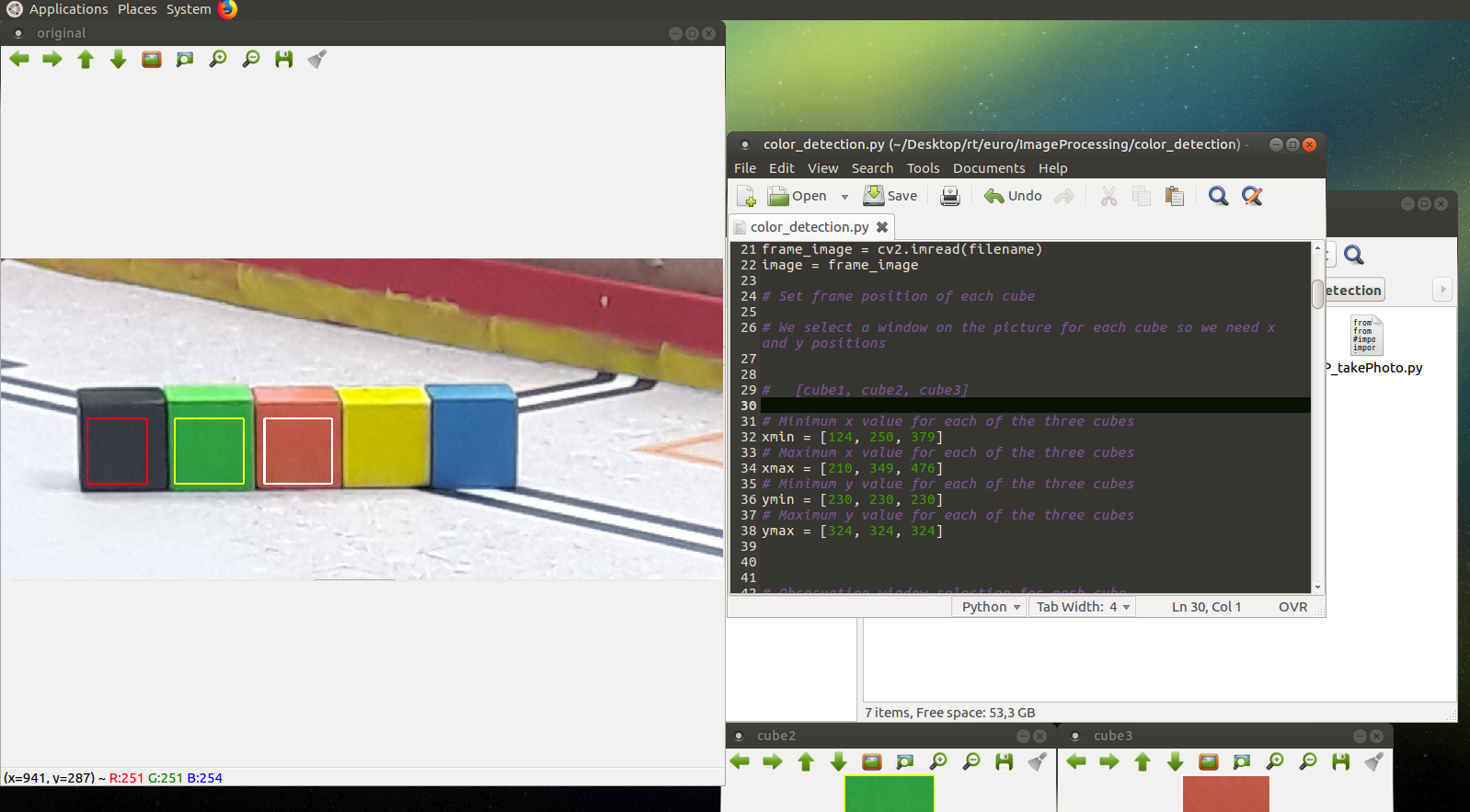

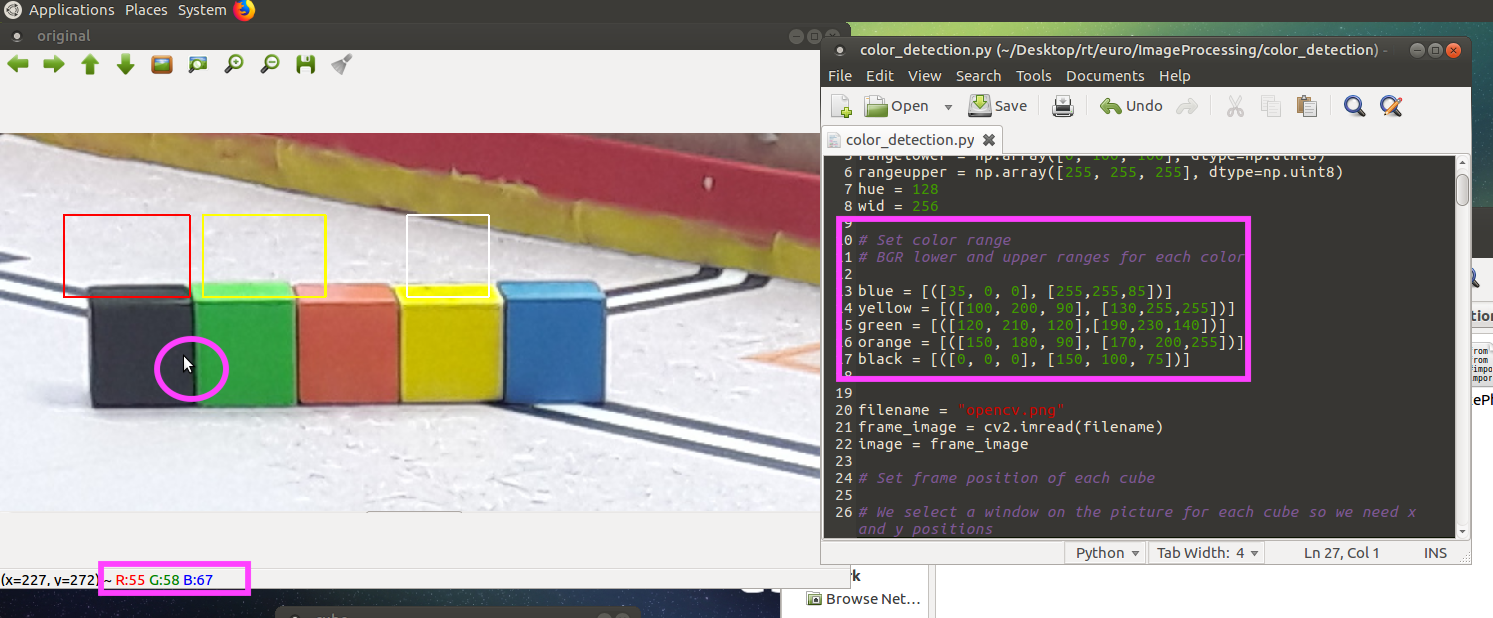

Thanks to the colour detection we know in which order we have to collect the blocks on the field, so we also know which one comes first in the lift and which floor it has to go to. It is important to know the specific floor in order to create the pattern showed at the beginning of the game and recognised by the colour and sequence recognition part.

To know when the lift has to stop, we use the encoder of the DC motor so we can precisely know when the motor has to stop. The encoder is connected to an interruption pin on the Arduino board so the tick counts can be more accurate and have priority.

Once the block is on the right floor, it has to be pushed outside of the lift to already be placed in its position on the tower on a kind of shelf (as you can see in the picture below) which supports the blocks even if there is no other block below.

Furthermore, to push the block, we use a dynamixel with a gear and a tooth rack to slide a plate along which pushes the block until it reaches the « shelf ».

Then the lift (without any block inside) goes down. To make sure it doesn’t go too much we use another limit switch. Therefore the lift is immediately stopped, another cube comes in and we can do the cube lifting steps mentioned before over again until all the cubes of the tower are placed.

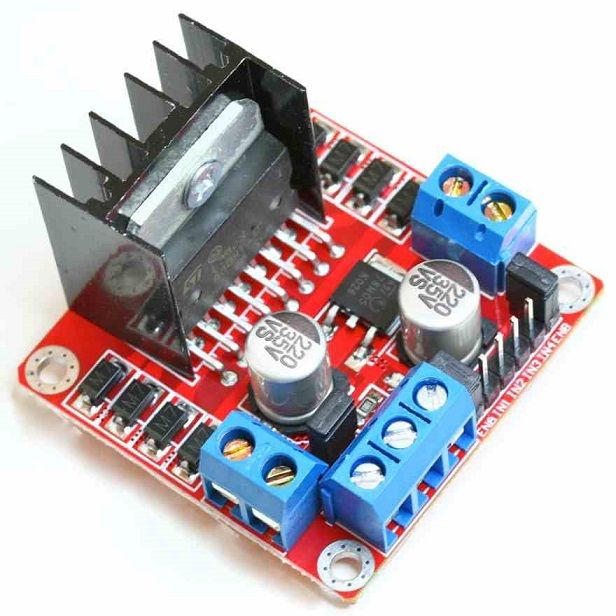

As mentioned above, we are using DC motors to control our lift. We have in all 3 motors and they are all connected to a L298 driver (see picture below) controlled by an Arduino Uno board.

Here is a link where you can buy the driver :

https://www.amazon.fr/L298-Motor-Driver/s?ie=UTF8&page=1&rh=i%3Aaps%2Ck%3AL298%20Motor%20Driver

We use 2 motors for the rollers to collect the blocks. In order to do so, each one has to turn in the opposite direction of the other but at the same speed. Thus we connected them to the same driver but inverted the pins of one motor compared to the other one. These motors don’t have an encoder so their only 2 pins are connected to the driver. We also have the third motor to make the lift go up and down. As we said before, we use the encoder to know where we have to stop so there are pins of the motor connected to the Arduino board. On the other hand the motor is also connected to the driver so we can control its speed, stop it and launch it.

The cage

The floors can rotate thanks to a dynamixel and a bearing wheel. To place the bearing wheel on the rotating axis we insert the last floor into the others floors with the bearing wheel between them as shown in the next figure :

External parts

Most of the part are home made (CNC, 3D printing) but some parts a bought on the market :

-

IGUS rail

- Small one

- Rail : Igus N Series, NS-01-17-300, Linear Guide Rail 17mm width 300mm length

- Carriage : Igus Linear Guide Carriage NW-02-17, N

- Big one :

- Rail : Igus N Series, NS-01-27-300, Linear Guide Rail 27mm width 300mm length

- Carriage : Igus Linear Guide Carriage NW-02-27, N

- Small one

-

Lift transmission

- Pitch (distance between teeth) : 2.032 mm

- Pulley : aluminium, Glass Filled PC Timing Belt Pulley, 6mm Belt Width x 2.032mm Pitch, 36 Tooth, Maximum Bore Dia. 5mm

- Timing belt : RS Pro, Timing Belt, 315 Tooth, 640.08mm Length X 6mm Width

-

Limit switch

- Snap Action Limit Switch, Roller Lever, Thermoplastic, NC, 125V

Authors

Crappe Martin

Hagopian Armen

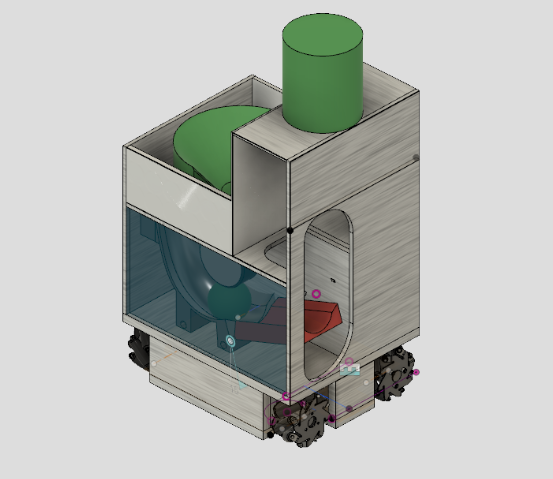

The Cortex (small) Robot

This year, the Eurobot task was water purification. As water is not practical around prototype electronics, they used balls to represent water. The balls of the same colour that is assigned to you during a match will represent clean/purified water whereas balls of the same colour as your opponents represent dirty water that has to be treated. To ease readability the word "balls" will be used synonymously with "water" for the rest of this article. We are also going to assume that the team colour assigned to our team is GREEN and therefore green balls = clean water and orange balls (the colour of the opponent team) = dirty water.

At the start of each match the Cortex robot has to collect 8 balls from two different containers on the playing field, sort them and then send them either to the "home tank" if they are green balls and into the reservoir if they are orange balls. We will take a look the mechanisms we put in place to collect, sort and send balls during each match for Eurobot 2018.

Ball Mechanism

Introduction

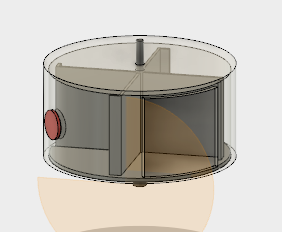

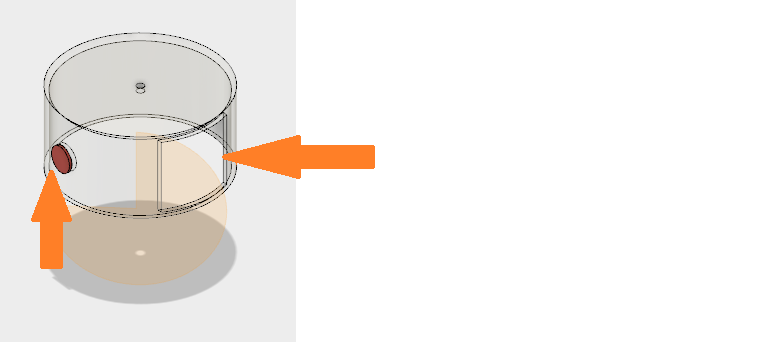

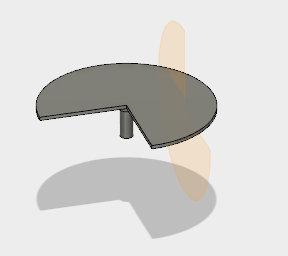

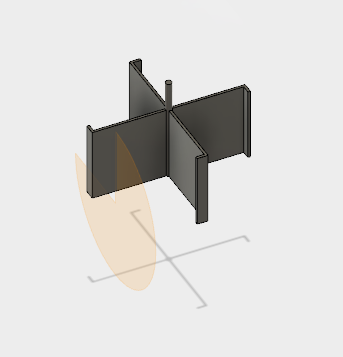

Initially, after much thought, we created a system composed of 3 basic parts and a colour detector. There are two parts that are mobile parts and one stagnant outer case. The system is divided into 4 compartments: the entry point, the colour sensor (CS) compartment, green trap compartment and the orange trap compartment. The colour detector is embedded in the stagnant outer case. Underneath the outer case is a moving plate controlled by an actuator (the dynamixel AX-12A) and a rotating "pusher" controlled by a stepper motor to move balls within the outer case.

Essentially there are 4 main steps for a ball to be separated in this system:

- The ball enters the mechanism at the entry point.

- The stepper motor activates and moves the ball to the CS compartment.

- The colour sensor detects the colour of the ball. Once the colour of the ball is known, the dynamixel AX-12A is activated and the opening of the mobile plate is moved into the corresponding colour position.

- The stepper motor activates and moves the ball into the green trap or orange trap.

The interest behind this idea is the fact that as the "pusher" is activated and moving another ball can enter at at the entry point and therefore creating a chain effect which we hoped would gain us time.

The outer case and colour sensor

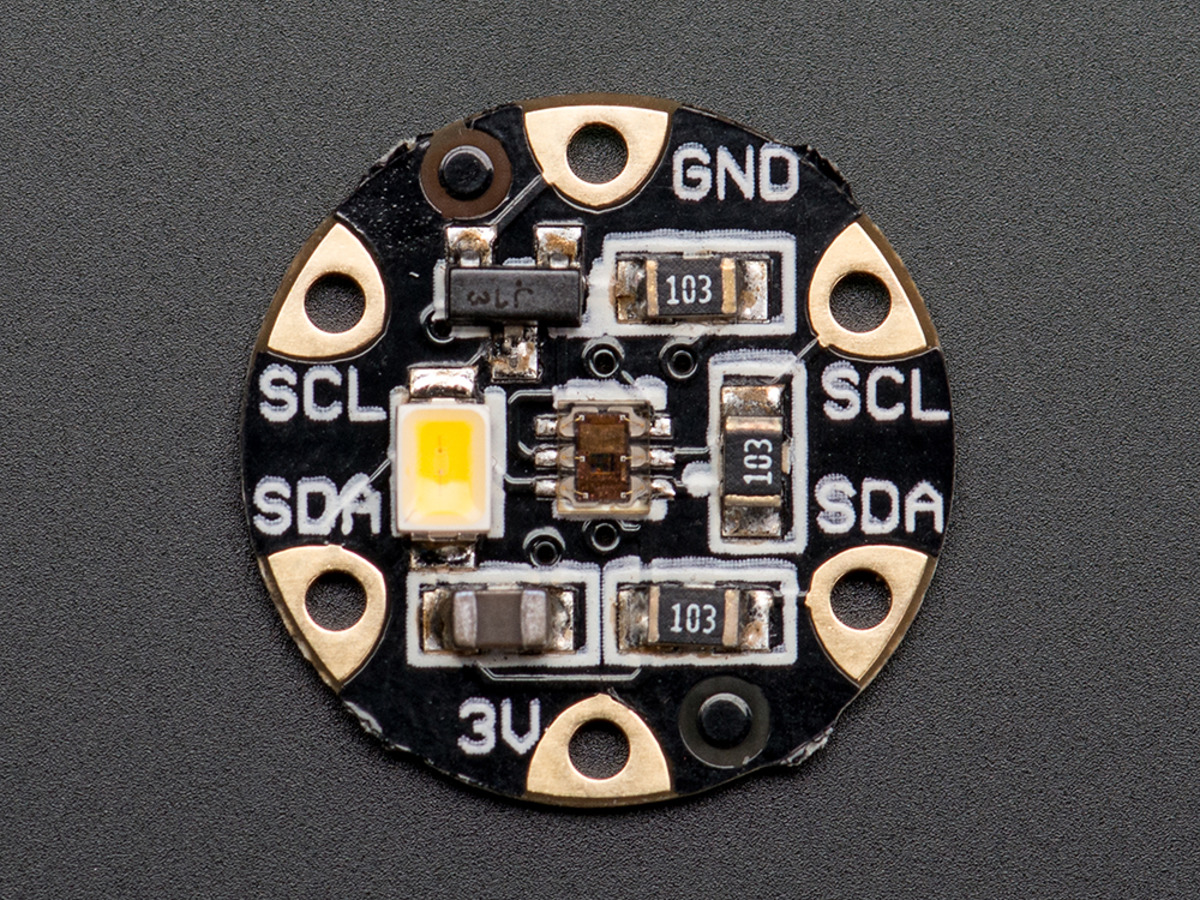

As you can see here we have the entry point and the colour sensor. How the colour sensor works and its corresponding code can be found in the sensors section.

The mobile plate

Control of the mobile plate was done with a dynamixel AX-12A.

The "pusher"

The pusher as well as the colour detector were eventually excluded from initial prototyping for the Cortex robot because of time constraints and on the basis of a strategic decision to simplify the mechanism for the qualifying stages. However, the link to an open-source library very useful for controlling stepper motors is supplied in this document under the actuator section as well.

Ball mechanism used in qualifying stages

This is the system that we used during qualifying stages which only makes use of a mobile plate and rounded edges on the sides and corners to guide the balls collected. The mobile plate was controlled by dynamixel and the corresponding code and application can be found under the actuators section of this report.

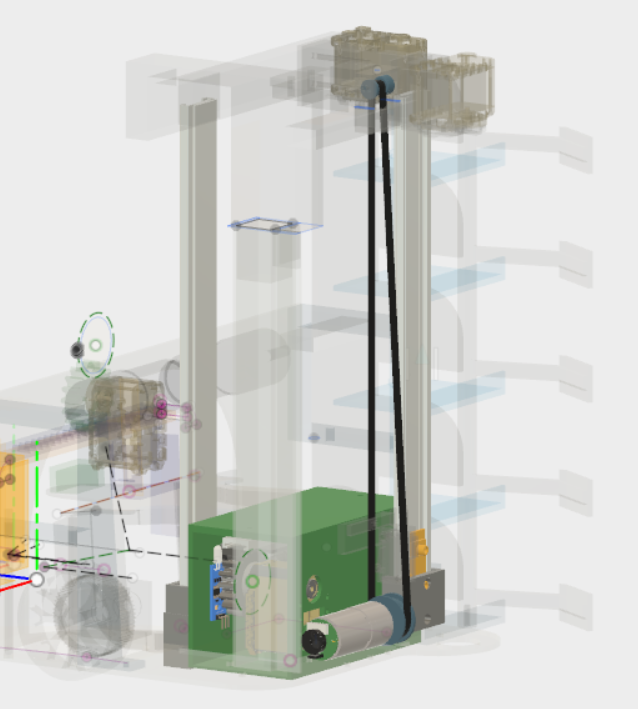

Ball Gun (Sending Mechanism)

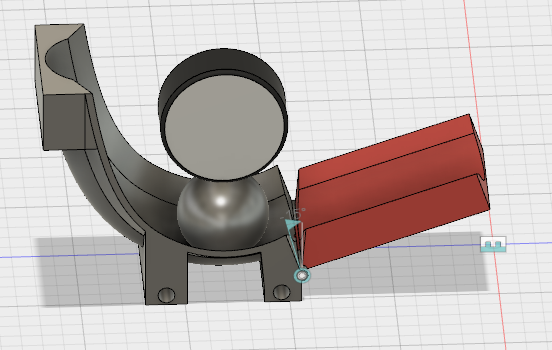

3D sketch

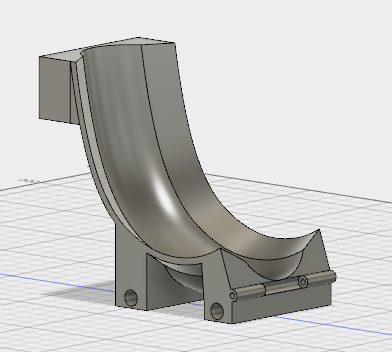

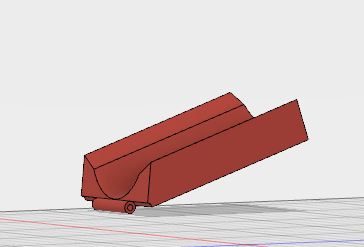

All the parts of the ball gun is designed on Fusion 360 and printed on a 3D printer except of the balls and the wheel.

Why a ball gun?

For the 2018 contest, we had to collect and sort balls by color and then put all the balls collected in the color of the team previously known in a big tank that made reference of a water castle as the balls made reference of water itself. The more balls we threw in the tank, the more points we earned.

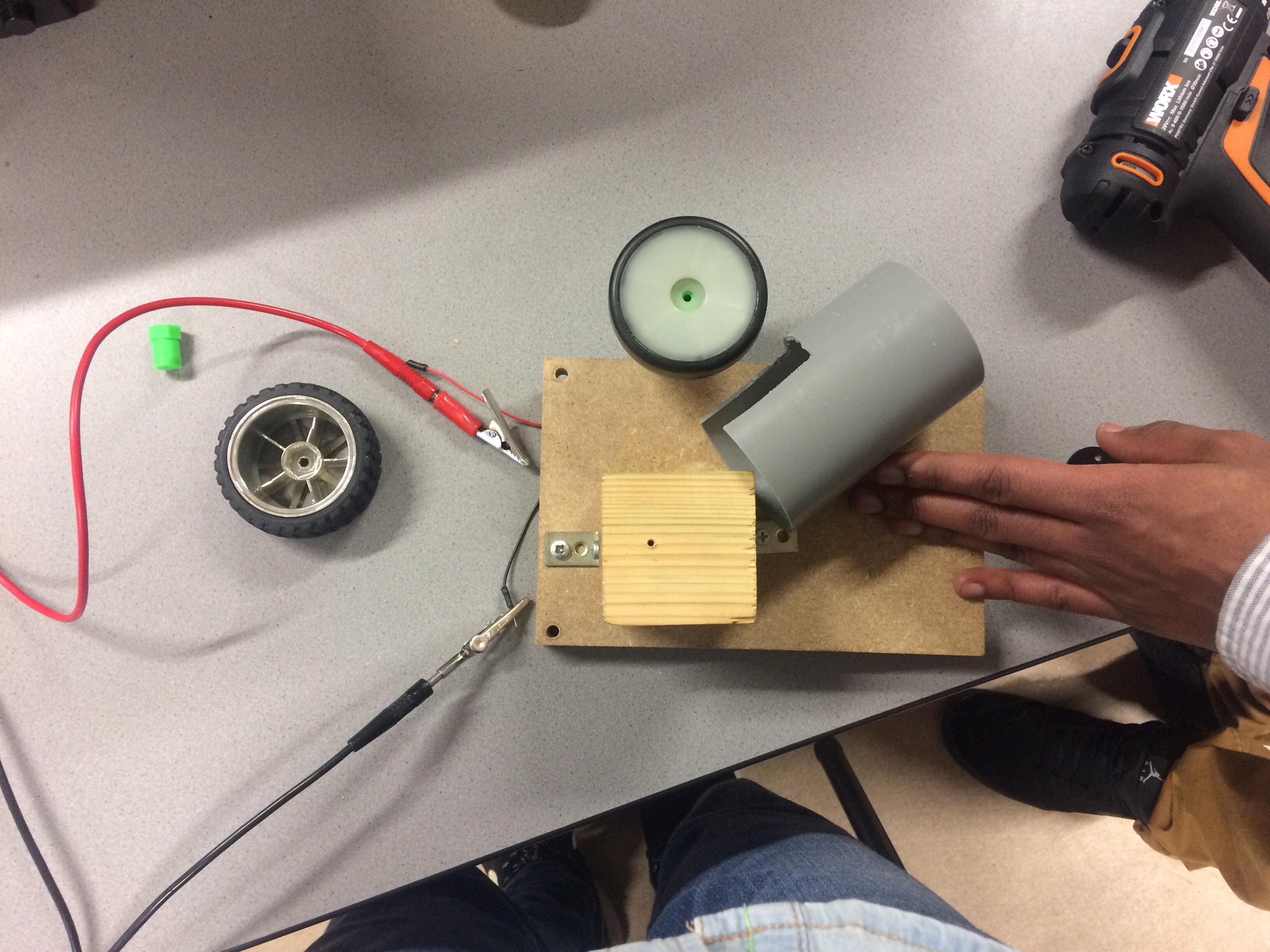

We choose to throw the balls with a gun made of a ramp for the direction of the ball and a wheel with a DC motor. as shown on the picture, you can see a fixed ramp, an adjustable ramp and the wheel.

Construction step by step

After lots of discussions with the team, I decided to choose the ball gun to complete the task of throwing balls in the tank. So I first made a prototype of the ball gun made of wood and a small DC motor I found in the lab but for the first tests it appeared that the small DC motor wasn't powerfull enough. So I choose a more powerfull and a better speed motor as a Maxon motor found in the lab and the results were very conclusive.

The next step was to control the speed of the wheel so we could control the distance the ball make after throwing by the ball gun.

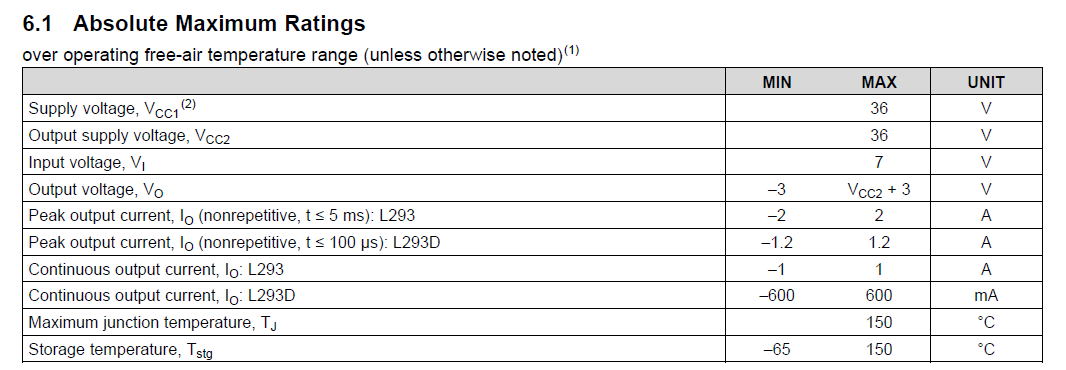

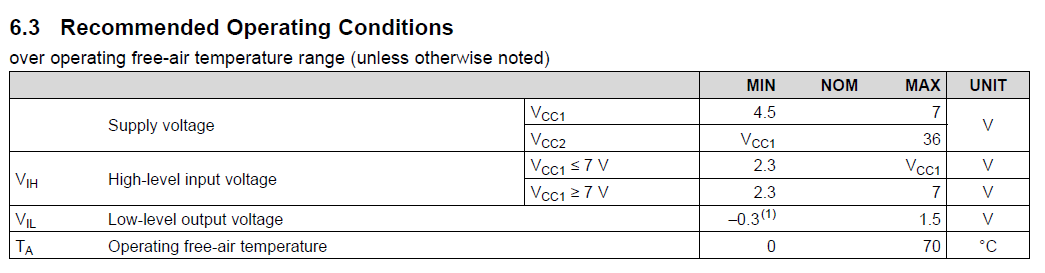

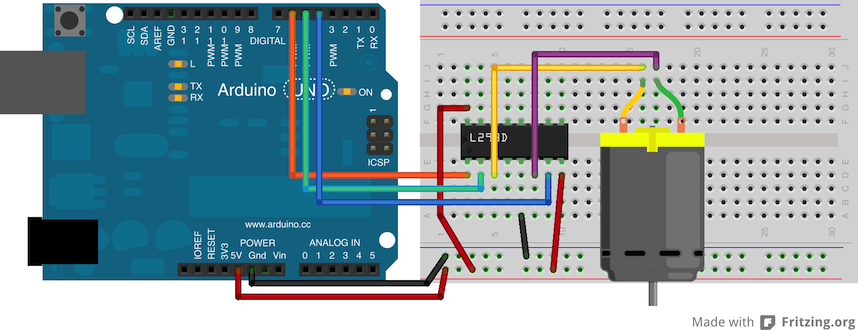

I used a small motor driver as the L293D which the specifications were in agreement with the needs of the DC motor.

You can find the datasheet of the L293D here : https://github.com/Ecam-Eurobot/Tutorials/tree/StevenGaro-patch-1/src/mechanical/2018/BallGun_SRC

To control the H bridge driver, I used a simple arduino uno with a PWM signal so we could test different speeds of the motor.

The precision of the distance the ball make was made experimentaly when we did the different tests.

The code I first used to test the driver with the motor is the next code in arduino :

int inputPin = A0; // set input pin for the potentiometer

int inputValue = 0; // potentiometer input variable

const int motorPin1 = 5; // Pin 14 of L293

const int motorPin2 = 6; // Pin 10 of L293

void setup() {

// declare the ledPin as an OUTPUT:

pinMode(motorPin1, OUTPUT);

}

void loop() {

// read the value from the potentiometer:

inputValue = analogRead(inputPin);

// send the square wave signal to the LED:

analogWrite(motorPin1, inputValue);

digitalWrite(motorPin1, HIGH);

delayMicroseconds(inputValue); // Approximately 10% duty cycle @ 1KHz

digitalWrite(motorPin1, LOW);

delayMicroseconds(1023 - inputValue);

}

When the tests were conclusive enough, we designed a ramp that fit in the robot correctly with an adjustable ramp for the ball to go higher or lower in case we need to modify the distance during the competition.

First we made the fixed ramp that comes from the ball sorting mecanism and end around the wheel.

After that we made a straight ramp that shows the ball the direction it must take.

And finaly, we designed a small piece that maintain the straight ramp from below and that you can adjust.

After that, all we had to do is to install the gun in the robot and make some tests to determine the best power to give as a PWM to the motor to throw the balls from the distance chosen in the tank and to incorporate the code of the ball gun in the main code of the robot.

Electronics

In the next chapters, we will describe all everything related to the electronics of the robots. Including:

- Technologies we used

- Printed circuit boards we designed

- How to use particular sensors

- How to use particular actuators

- ...

Introduction

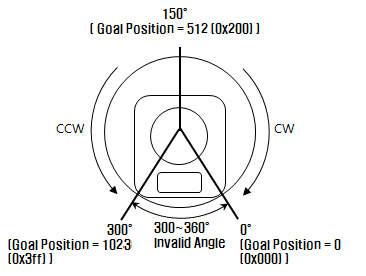

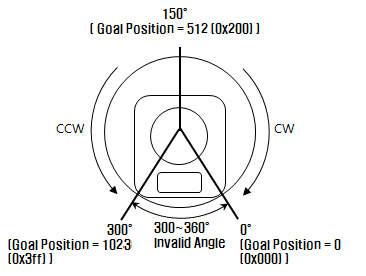

Dynamixels are servomotors with a working angle of 300° dispatched on values 0 to 1023.

They also have the particularity of beeing able to be used as DC motor. They have a very good motor torque what makes them efficient for a big number of applications. In our robots, we used them for the tasks the robots had to realise during the competition as :

- Sort balls of different colors

- Deploy an arm to push an object on wheels

- Deploy a platform on multiple floors to liberate cubic blocks

- Maintaining the blocks on every floor or not

- Actionate a gear to move blocks

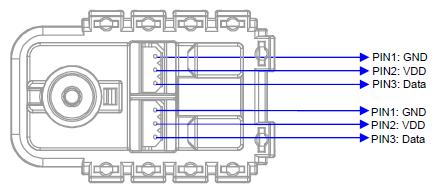

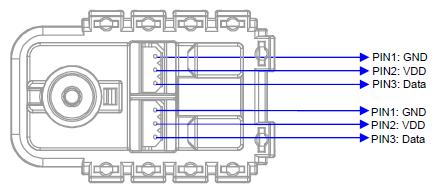

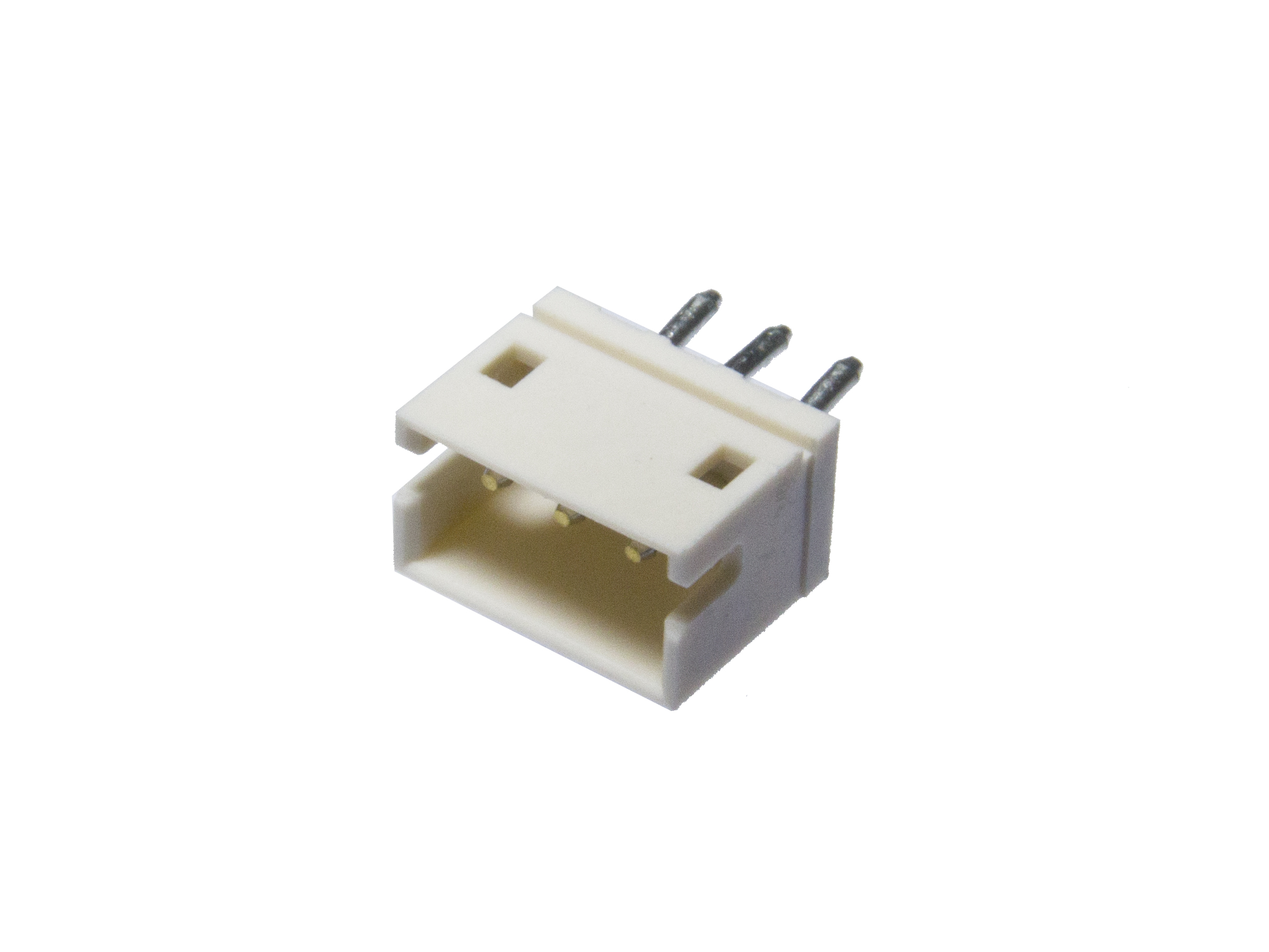

The cabling is made with JST 3 pin connectors from a servomotor to another.

Here is a link on amazon to order some : https://www.amazon.fr/ensembles-Micro-connecteur-Fiche-150mm/dp/B01DU9OY40/ref=sr_1_2?ie=UTF8&qid=1525997056&sr=8-2&keywords=jst+connecteur+3+pin&dpID=51oVa4jux4L&preST=SY300_QL70&dpSrc=srch

The Dynamixels have 2 locations for these connectors because it is possible to connect several servomotors in series and to control them with an addressing. These adresses are represented by unique ID for every dynamixel and it is possible to check with the software Dynamixel Wizard of Roboplus and a USB2Dynamixel.

Thanks to this software, it is also possible to configurate the dynamixels (registers) like, among others, the baudrate of the servomotor and also to access a serie of informations in real time like the speed, the position, etc.

Description

Dynamixels are servomotors with a working angle of 300° dispatched on values 0 to 1023.

They also have the particularity of beeing able to be used as DC motor. They have a very good motor torque what makes them efficient for a big number of applications. In our robots, we used them for the tasks the robots had to realise during the competition as :

- Sort balls of different colors

- Deploy an arm to push an object on wheels

- Deploy a platform on multiple floors to liberate cubic blocks

- Maintaining the blocks on every floor or not

- Actionate a gear to move blocks

The cabling is made with JST 3 pin connectors from a servomotor to another.

Here is a link on amazon to order some : https://www.amazon.fr/ensembles-Micro-connecteur-Fiche-150mm/dp/B01DU9OY40/ref=sr_1_2?ie=UTF8&qid=1525997056&sr=8-2&keywords=jst+connecteur+3+pin&dpID=51oVa4jux4L&preST=SY300_QL70&dpSrc=srch

The Dynamixels have 2 locations for these connectors because it is possible to connect several servomotors in series and to control them with an addressing. These adresses are represented by unique ID for every dynamixel and it is possible to check with the software Dynamixel Wizard of Roboplus and a USB2Dynamixel.

Thanks to this software, it is also possible to configurate the dynamixels (registers) like, among others, the baudrate of the servomotor and also to access a serie of informations in real time like the speed, the position, etc.

Specifications

- Weight : 53.5g (AX-12/AX-12+), 54.6g (AX-12A)

- Dimension : 32mm * 50mm * 40mm

- Resolution : 0.29°

- Gear Reduction Ratio : 254 : 1

- Stall Torque : 1.5N.m (at 12.0V, 1.5A)

- No load speed : 59rpm (at 12V)

- Running Degree : 0° ~ 300° or Endless Turn

- Running Temperature : -5℃ ~ +70℃

- Voltage : 9 ~ 12V (Recommended Voltage 11.1V)

- Command Signal : Digital Packet

- Protocol Type : Half duplex Asynchronous Serial Communication (8bit,1stop,No Parity)

- Link (Physical) : TTL Level Multi Drop (daisy chain type Connector)

- ID : 254 ID (0~253)

- Communication Speed : 7343bps ~ 1 Mbps

- Feedback : Position, Temperature, Load, Input Voltage, etc.

- Material : Engineering Plastic

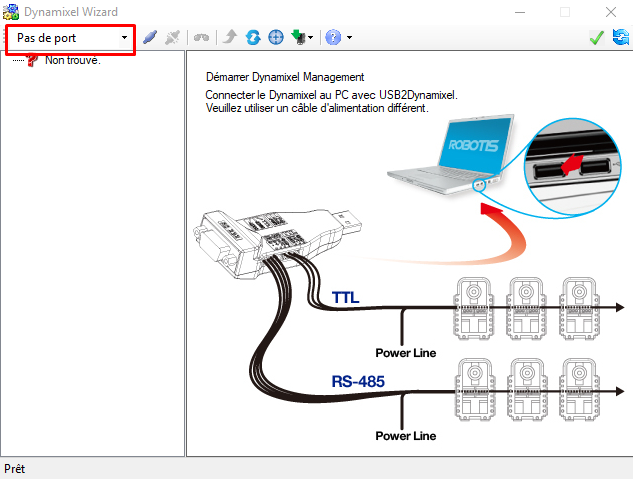

Dynamixel Wizard

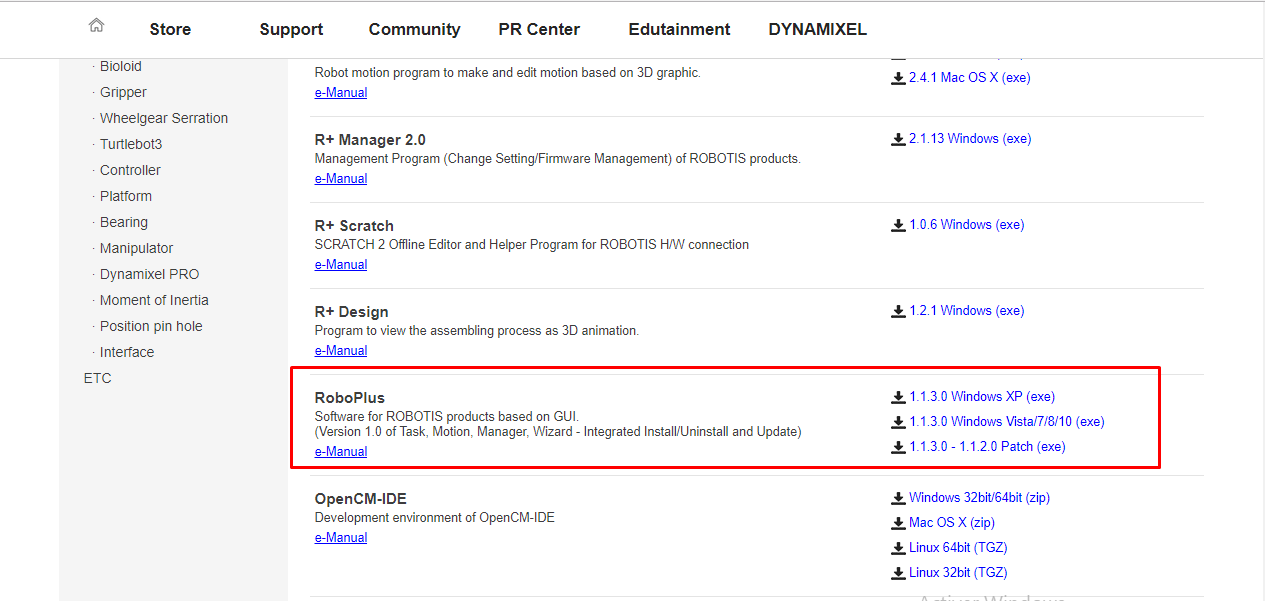

- Download and install the software "Roboplus" on the website www.robotis.com when going in Support>Download>Software>Roboplus

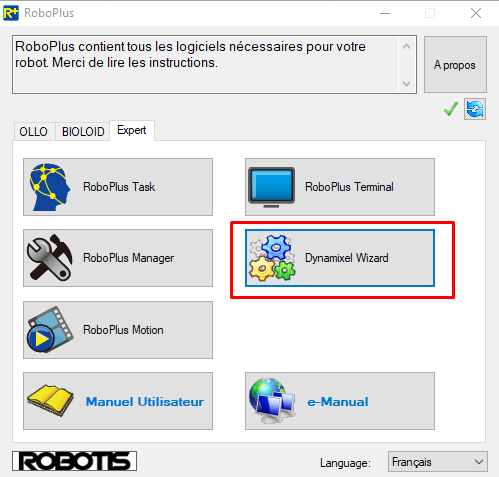

- Launch the software and clic on Dynamixel Wizard

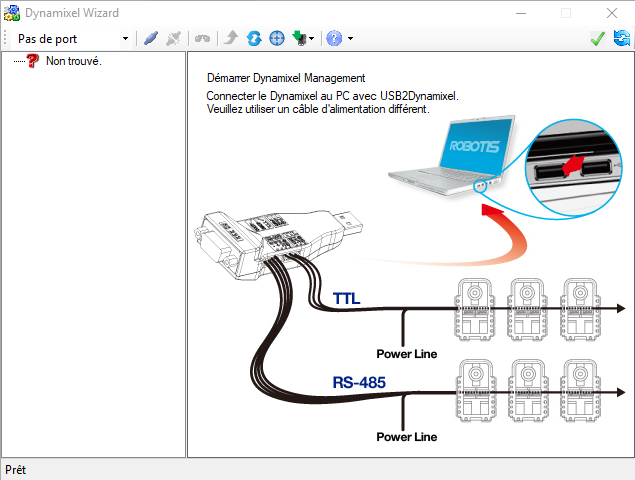

- Insert the USB2Dynamixel in the USB port of the computer

- Connect the 3 pins JST connector in the USB2Dynamixel (TTL side) ansd the dynamixel to verifie or configure

- Select « TTL » with the switch on the USB2Dynamixel

- Supply the dynamixel separately in its working voltage (9-12V, recommanded 11,1V) with the second port of the dynamixel

- Select the port of your computer where the USB2Dynamixel is connected

- Clic on "Open Port"

- Make a basic research of the dynamixel to find its ID

-

It is also possible to make advanced research on other baudrates in case of the basic research is not working

-

Once the dynamixel found, selct it on the left side of the window

-

The details of the informations of the dynamixel appears

-

in these details, it is possible to modify the configuration of the dynamixel like its ID, its communication speed (baudrate), its working speed, etc, or also to control it in real time.

Examples of use

To use the dynamixels, it is necessary to download first the library "AX_12A_servo_library" that you can find on the github of eurobot here : https://github.com/Ecam-Eurobot/Tutorials/tree/master/src/electronics/actuators/Dynamixels_SRC

You'll have to extract it and place it in Documents/Arduino/libraries.

To configure the dynamixels, we'll use the Arduino software app.

This library possess 4 exemples of use of the dynamixel :

- Blink : example of control of the red led you can find in the back of every dynamixel

- Move : example of control of the dynamixel in servomotor mode by giving it a position

- EndlessTurn : example of use in DC motor mode (or wheel mode)

- ReadRegister : usefull to dispaly the contents of the registers of the dynamixel

These examples are located in Fichier>Exemples>AX-12A on the Arduino app on your computer.

After selecting one of the examples, you have to include the library AX-12A without declaring a specific path because the library is located in the fold "libraries" of the fold "Arduino".

After that you have to configure 3 lines in the code that respond to the needs of the configuration of the connected dynamixel you want to configure :

#define DirectionPin (10u)

#define BaudRate (1000000ul)

#define ID (1u)

"DirectionPin" is used to indicate the communication direction of the dynamixel. 10u is for writing in the registers so you don't have to change the value.

"BaudRate" defines the communication speed used ( and configurate before with the Dynamixel Wizard)

"ID" represents the ID of the dynamixel that you checked or configured before for the addressing.

Application with ROSserial

As explained in the section "Ball Mechanism", one dynamixel was used to control the separation of coloured balls (one colour representing dirty water and the other clean water). This dynamixel has three main positions:

- Initial_pos_purifier (blocked or closed) position

- Clean ball position (opens trap for green balls as in our earlier example)

- Dirty ball position (Open trap for orange balls as in our earluer example)

Another task that Cortex robot had was to push a bee for the foraging task. This meant we needed a mechanical hand that extended from the robot in order to push the bee. We used a dynamixel for this action as well. This dynamixel has two main positions:

- initial_pos_bee (embedded inside robot)

- push_pos (extended from robot)

We calibrated these positions using the angle diagrams supplied in the data sheet and the good old "trial and error method".

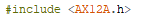

Schematic block Diagram

The communication between the ROS board (Rasberry pi with ROS installed) and the Arduino Uno board that controls the tasks of the Cortex robot takes place over a USB serial communication better known as ROSserial. The concepts behind ROSserial are explored in detail in the chapter "Software" of this document. I personally recommend reading that section to better understand the code presented here.

The three main actions of the Arduino board are:

- Separate dirty balls from clean balls (without colour detection and pusher in qualifying stages)

- Push bee

- Drive DC motor to shoot clean balls into home tank.

These actions are activated and controlled fully by the ROS board. That is, if the ROS board wants to push the bee, the Arduino board must be ready to receive the message and activate the right actuators in order to push the bee.

! Attention: It is imperative to program the dynamixels to the right baudrate first! This can be done using the USB2Dynamixel and Dynamixel Wizard software as explained earlier. We had problems controlling the dynamixels via the ROS board at the default baudrate of 1000000 BPS. The communication speed that worked best was the default baudrate used by ROS on the Raspberry pi, 57600 BPS. After setting the dynamixel in the wizard, all you have to do is change the baudrate in the code from 1000000ul to 57600ul. (Note: 1000000ul works fine when controlling the dynamixels with only the Arduino board, hmm).

! Attention: These dynamixels use UART to communicate, if you use the Arduino Uno which only has one on board UART module then you will not be able to use the serial monitor at the same time! DO NOT PUT SERIAL.BEGIN IN SETUP when you want to work with the dynamixels on an Arduino Uno. The best case would be to use a board with more than one UART module, allowing you to control the dynamixels independent of the serial monitor.

Code

#include <ros.h>

#include <std_msgs/Bool.h>

#include <std_msgs/Int16.h>

#include <AX12A.h>

//Ax-12A IDs and baudrate

#define DirectionPin (10u)

#define BaudRate (57600ul)

#define ID1 (7u) //water purification

#define ID2 (1u) //bee

//Gun pin definitions

#define i1 5

#define i2 4

#define ena_pwm 9 //PWM pin at 490Hz

//Water purification definitions

#define clean_ball_position 90

#define dirty_ball_position 916

#define initial_pos_purifier 512

//int initial_pos_purifier = 512;

//water purification declarations

int servo_speed = 500; //speed for ax-12a movement

//Dynamixel AX-12A definitions and global variables

//for control of valve used to separate/purify balls/water.

//@param valve_pos is controlled by ROS board.

int initial_pos_bee = 552;

int valve_pos;

//Start ROS handle.

ros::NodeHandle nh;

void moveBee( const std_msgs::Bool & position_msg){

// Bool variable decides whether to push bee

// or return to initial position. False = initial position

// True = push bee position

bool pushbee = false;

int pushbee_pos = 30; // initial/push position for bee still needs to be calibrated

pushbee = position_msg.data;

if(pushbee){

//ax12Move(ID2, pushbee_pos, servo_speed);

ax12a.moveSpeed(ID2, pushbee_pos, servo_speed);

}

else {

//ax12Move(ID2, initialpos, servo_speed);

ax12a.moveSpeed(ID2, initial_pos_bee, servo_speed);

}

}

void moveValve(const std_msgs::Int16 & pos_msg){

valve_pos = pos_msg.data;

if(valve_pos == 1){

ax12a.moveSpeed(ID1, clean_ball_position, servo_speed);

}

else if (valve_pos == 2){

ax12a.moveSpeed(ID1, dirty_ball_position, servo_speed);

}

else if(valve_pos == 3){

ax12a.moveSpeed(ID1, initial_pos_purifier, servo_speed);

}

}

void shootGun( const std_msgs::Int16 & dutycycle_msg){

//Gun declarations. @param dutycycle (0-255) is controlled

//by ROS board.

int dutycycle = 0;

dutycycle = dutycycle_msg.data;

//direction

digitalWrite(i1, LOW);

digitalWrite(i2, HIGH);

//Drive

analogWrite(ena_pwm, dutycycle);

}

//Move purifier to and fro in order to make

//sure all balls enter compartment

void shake(void);

ros::Subscriber<std_msgs::Bool> bee_ctrl("bee_control", &moveBee);

ros::Subscriber<std_msgs::Int16> ballseparator_ctrl("water_purification", &moveValve);

ros::Subscriber<std_msgs::Int16> gun_ctrl("gun_control", &shootGun);

void setup() {

pinMode(ena_pwm , OUTPUT);

pinMode(i1, OUTPUT);

pinMode(i2, OUTPUT);

//Start-up

ax12a.begin(BaudRate, DirectionPin, &Serial);

//Remove endless rotation

ax12a.setEndless(ID1, OFF);

ax12a.setEndless(ID2, OFF);

//move into initial position

ax12a.moveSpeed(ID1, initial_pos_purifier, servo_speed);

ax12a.moveSpeed(ID2, initial_pos_bee, servo_speed);

nh.initNode();

nh.subscribe(bee_ctrl);

nh.subscribe(ballseparator_ctrl);

nh.subscribe(gun_ctrl);

}

//the loop contains is empty.

void loop() {

nh.spinOnce();

//delay(50);

//shake();

}

void shake(void)

{

int dir = 0;

int current_pos = ax12a.readPosition(ID1);

if (valve_pos == 1){

if (dir == 0){

if (current_pos != clean_ball_position + 200){

ax12a.moveSpeed(ID1, clean_ball_position + 200, servo_speed);

}

else {

dir = 1;

}

}

else if (dir == 1){

if (current_pos != clean_ball_position){

ax12a.moveSpeed(ID1, clean_ball_position - 200, servo_speed);

}

else {

dir = 0;

}

}

}

if (valve_pos == 2){

if (dir == 0){

if (ax12a.readPosition(ID1) != dirty_ball_position + 200){

ax12a.moveSpeed(ID1, dirty_ball_position - 200, servo_speed);

}

else {

dir = 1;

}

}

else if (dir == 1){

if (ax12a.readPosition(ID1) != dirty_ball_position){

ax12a.moveSpeed(ID1, dirty_ball_position + 200, servo_speed);

}

else {

dir = 0;

}

}

}

}

Note: ROS library packages are bulky and can get very big, adding more #includes or libraries to your code will mean more global variables to your overall project. Make sure that your board, Uno, Nano etc. has enough memory space) for the large amount of global variables. I invite you to compile this code and load it on an Arduino board. Check the memory details after loading, you will see that we're already almost at the limit ! Think about this for the future.

How it works

Libraries

Include all libraries that are necessary for the application but be sure to include ros.h first! Here we will need the AX12A library to control the dynamixel servo motor. We also need certain source code from the ROSserial std_msgs (allows for communication over ROSserial) package. These source code files that we include will determine the type (int, foat64, String etc..) of the messages that will be exchanged between the Arduino board and the ROS board.

To control the position of the "bee dynamixel" we only need a true or false signal from ROS but for the "water purifier" we need three positions so we'll rather go for the type int here. The choice is yours.

Note: We had difficulties working with the std_msgs: Int8 and String when programming with the dynamixels so we settled with Int16 and Bool.

#include <ros.h> //ROS packages

#include <std_msgs/Bool.h> //ROS std messages needed for com

#include <std_msgs/Int16.h>

#include <AX12A.h> //Dynamixel control

Declarations and pin definitions

Declare as many variables as possible through the #define method in order to save global variable space on the Arduino Uno, for example:

//Gun pin definitions

#define i1 5

#define i2 4

#define ena_pwm 9 //PWM pin at 490Hz

//water purification declarations

int servo_speed = 500; //speed for ax-12a movement

Don't forget to create the ROS node!

//Start ROS handle.

ros::NodeHandle nh; //Create a ROS node

Create callback function

The Arduino board is seen as a node by the ROS board. In order to receive commands from it we need to subscribe to a topic to see what the ROS board has sent us. This is how we create a topic and a callback function:

//For ROS, the name of the topic is gun_control and the ROS board can send

//messages only of type Int16. The name of the function in Arduino that needs

//to be called every time we receive a message is shootGun

ros::Subscriber<std_msgs::Int16> gun_ctrl("gun_control, &shootGun);

Now we need to implement the call back function, for example the callback function for the water_purification topic:

void moveValve(const std_msgs::Int16 & pos_msg){

valve_pos = pos_msg.data; //Get data sent from ROS

if(valve_pos == 1){

ax12a.moveSpeed(ID1, clean_ball_position, servo_speed); //cross-reference library for more info

}

else if (valve_pos == 2){

ax12a.moveSpeed(ID1, dirty_ball_position, servo_speed);

}

else if(valve_pos == 3){

ax12a.moveSpeed(ID1, initial_pos_purifier, servo_speed);

}

}

Set-up

We need to setup the dynamixel, subscribe to the our topics and we need to initialise the ROS node we created.

//Start-up

ax12a.begin(BaudRate, DirectionPin, &Serial);

//Remove endless rotation

ax12a.setEndless(ID1, OFF);

ax12a.setEndless(ID2, OFF);

//move into initial position

ax12a.moveSpeed(ID1, initial_pos_purifier, servo_speed);

ax12a.moveSpeed(ID2, initial_pos_bee, servo_speed);

nh.initNode();

nh.subscribe(bee_ctrl);

nh.subscribe(ballseparator_ctrl);

nh.subscribe(gun_ctrl);

loop

Keep it simple. Do not over load the loop. We want to nh.spinOnce to to be called as often as possible without interruption.

nh.spinOnce(); //Checks topics that we subscribed to and calls callback function if ROS board has published something correctly.

What ROS needs to send

To properly implement this code, you will need a ROS board and an Arduino board. The default baudrate is 57600 with ROS. ROS needs to publish:

- true or false to the topic "bee_ctrl" to position dynamixel

- 1, 2 or 3 to the topic "ballseparator_ctrl" to position dynamixel

- 0-255 to set the duty cycle of the PWM signal at pin 9 of the Arduino.

References

-

e-manual : http://support.robotis.com/en/

-

youtube vidéo for all the steps of the use of the Dynamixel Wizard : https://www.youtube.com/watch?v=YJ9b68hx5Qc&version=3&hl=ko_KR

-

website of the manufacturer : http://en.robotis.com

-

AX-12A library : https://github.com/ThingType/AX-12A-servo-library

Sonar

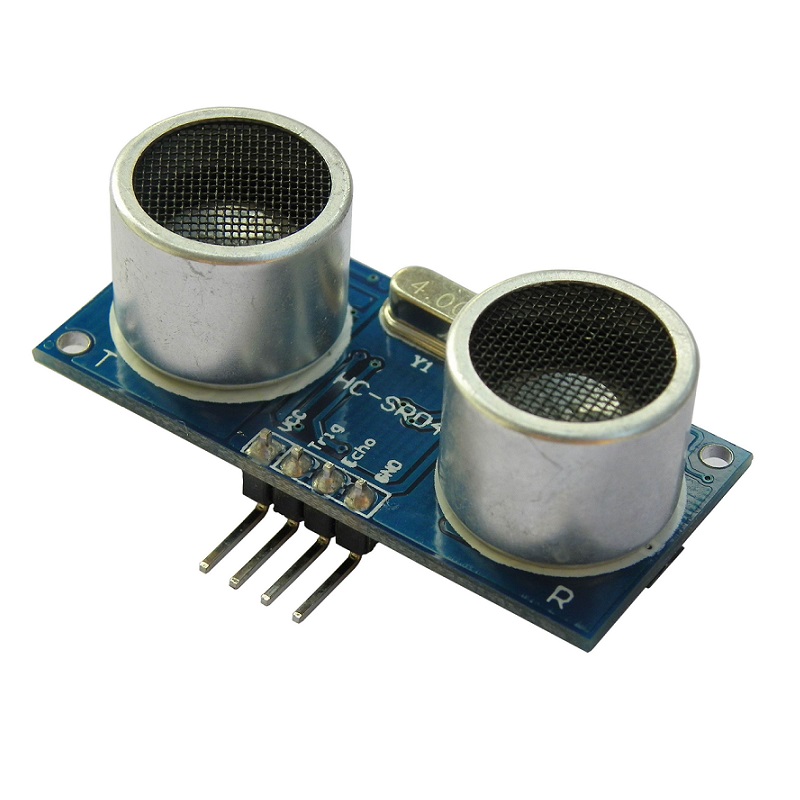

A sonar is a sensor allowing you to measure the distance to an obstacle thanks to high frequency waves. To keep correct measured values it is better to use the sensor we chose between 2cm and 400cm. The model of our sonar is HC-SR04. There are 4 pins on this sensor : TRIG, ECHO, VCC and GND (as you can see on the picture below).

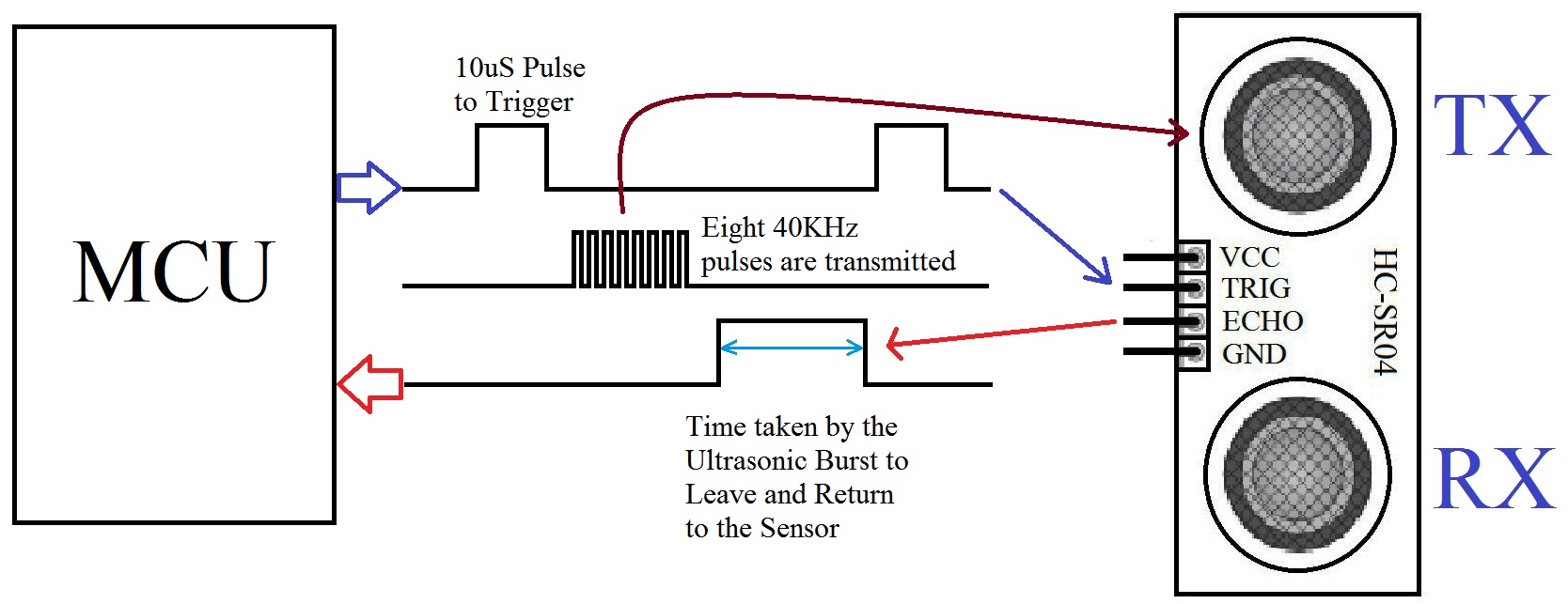

It contains a transmitter and a receiver. The distance measure is pretty simple. Firstly, you have to send a signal on the TRIG pin so the sonar emits a wave of 8 pulses at 40kHz. Then the ECHO pin is set to the «HIGH» level until the emitted signal goes to the obstacle and comes back to the sensor (as you can see on the following picture).

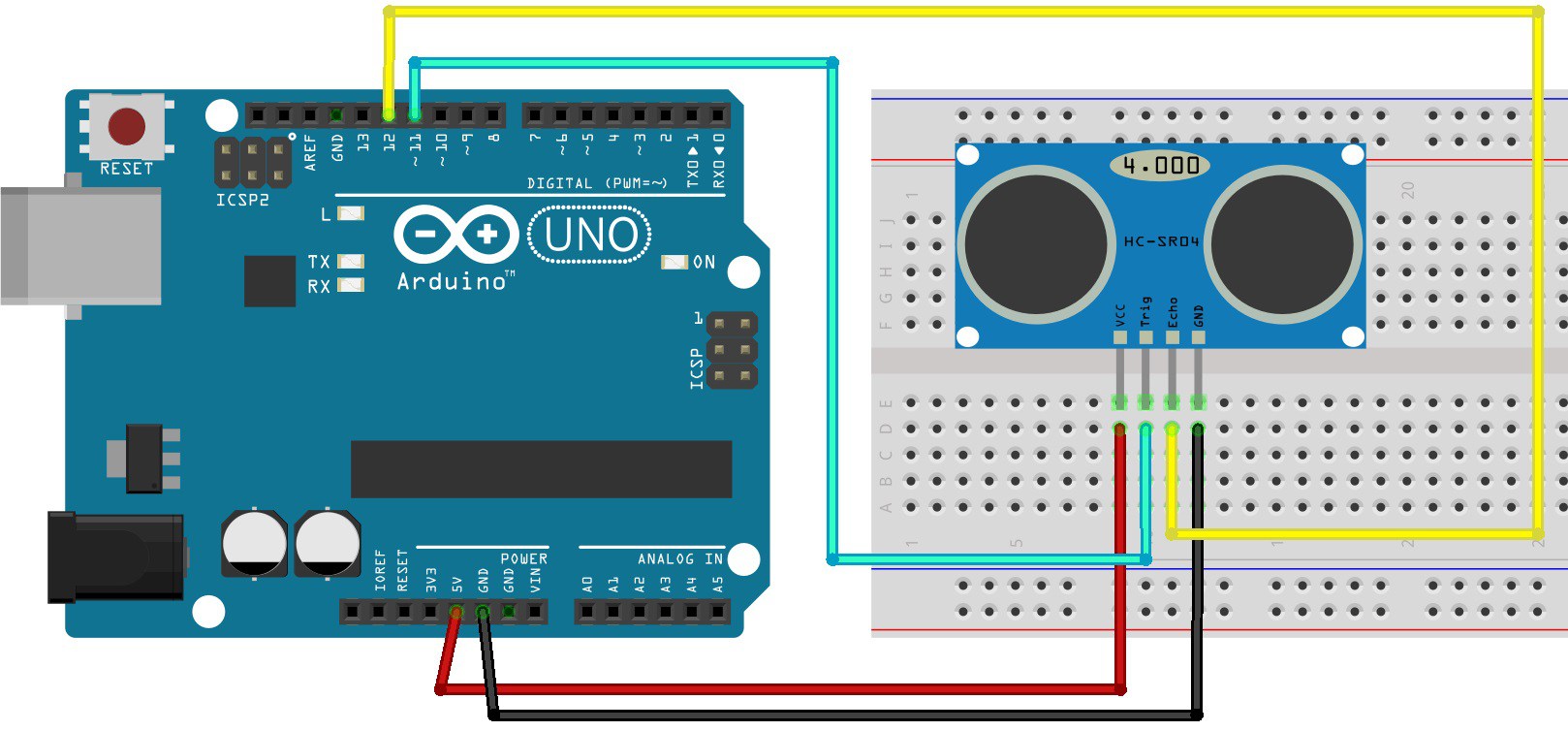

Of course, you have to connect the sensor to a microcontroller. You can connect the VCC to the 5V pin of your board, the GND to the ground pin and the TRIG and ECHO to digital pins of your controller as illustrated on the picture below.

Finally it is also important to know that the measuring angle with the HC-SR04 sonar is 30 degrees. Which is short, so the sonar can only see in front of him

All these information are also explained in the following websites :

https://www.gotronic.fr/pj2-hc-sr04-utilisation-avec-picaxe-1343.pdf

https://wiki.mchobby.be/index.php?title=HC-SR04

http://web.eece.maine.edu/~zhu/book/lab/HC-SR04%20User%20Manual.pdf

Here is an online store where you can buy this sensor :

https://shop.mchobby.be/proximite/561-senseur-ultrason-hc-sr04-3232100005617.html

Images references :

http://www.instructables.com/id/HC-SR04-Ultrasonic-Sensor-With-Raspberry-Pi-2/

https://randomnerdtutorials.com/complete-guide-for-ultrasonic-sensor-hc-sr04/

Tutorial

Simple Arduino code

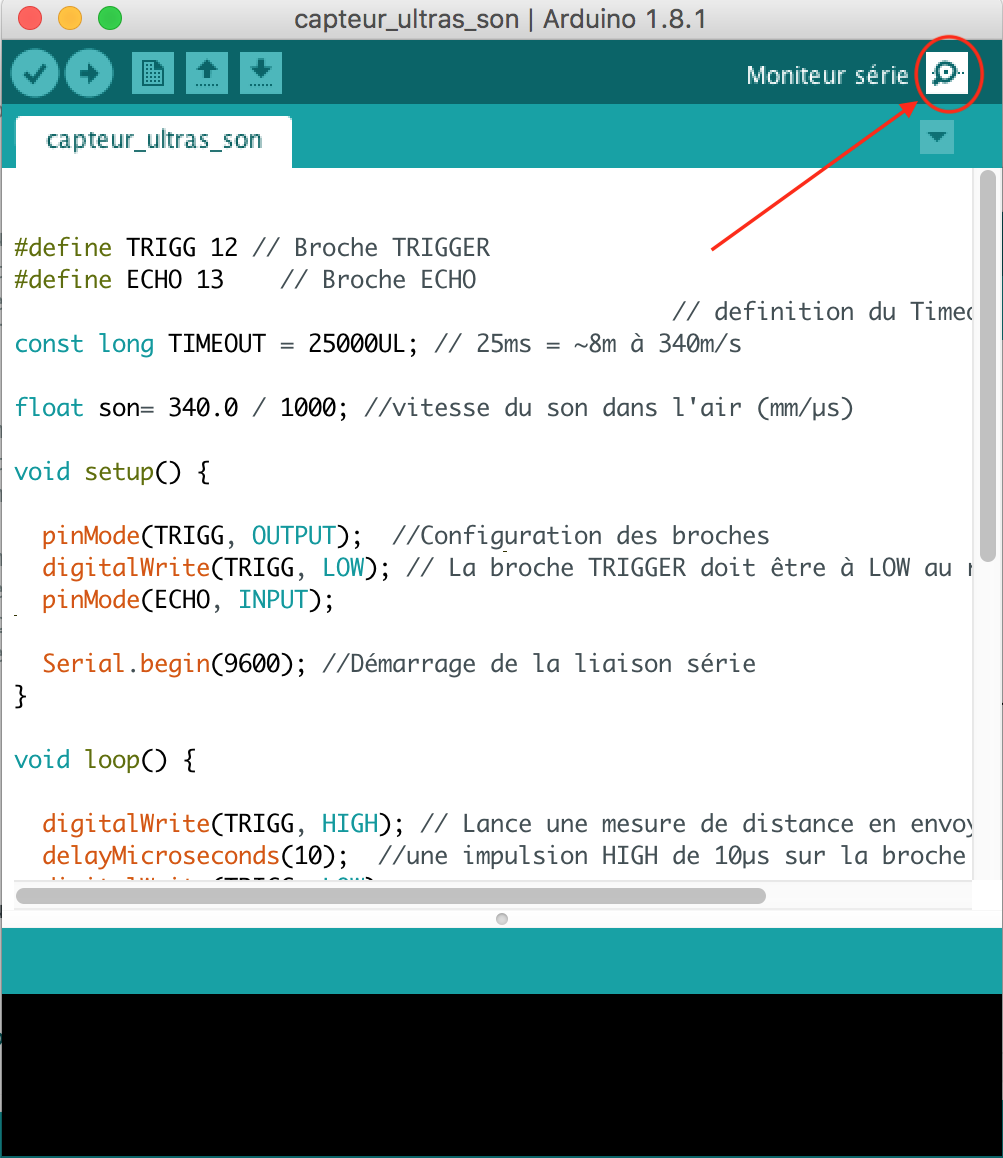

To be able to test the simple code showed in this part you have to connect the sonar sensor to your Arduino Uno board as showed on the third picture hereinabove. You also have to connect the TRIGG pin of the sonar to the pin 12 on your Arduino board and the ECHO pin of the sonar to the pin 13 on the Arduino board. Of course you can change these values on the following code if needed.

You are now ready to upload the code :

#define TRIGG 12 // Broche TRIGGER

#define ECHO 13 // Broche ECHO

// definition du Timeout

const long TIMEOUT = 25000UL; // 25ms = ~8m à 340m/s

float son= 340.0 / 1000; //vitesse du son dans l'air (mm/µs)

void setup() {

pinMode(TRIGG, OUTPUT); //Configuration des broches

digitalWrite(TRIGG, LOW); // La broche TRIGGER doit être à LOW au repos

pinMode(ECHO, INPUT);

Serial.begin(9600); //Démarrage de la liaison série

}

void loop() {

digitalWrite(TRIGG, HIGH); // Lance une mesure de distance en envoyant